Welcome to Part 20 of our free YouTube lecture series, where we aim to educate you about the latest technologies. In this episode, we will delve into the fascinating world of industrial robots and explore the different types that exist.

Industrial robots have revolutionized the manufacturing industry, enabling faster production, improved efficiency, and increased precision. These robots are designed to perform repetitive tasks with high speed and accuracy, making them an invaluable asset in various industries.

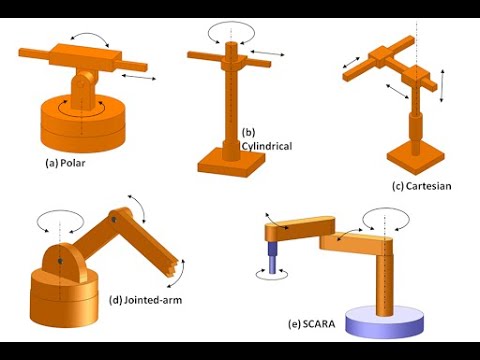

Types of Industrial Robots:

1. Articulated Robots: These robots have rotary joints, similar to a human arm, allowing them to move freely in multiple directions. Articulated robots are widely used in assembly lines, welding, material handling, and painting applications.

2. Cartesian Robots: Also known as gantry robots, Cartesian robots move in a three-dimensional rectangular coordinate system. They are often used for pick and place operations, packaging, and palletizing tasks.

3. SCARA Robots: SCARA stands for Selective Compliance Assembly Robot Arm. These robots have a rigid vertical arm and a horizontal arm with rotational joints. SCARA robots excel in tasks that require fast and accurate vertical and horizontal movements, such as assembly and material handling.

4. Delta Robots: Delta robots are known for their incredible speed and precision. They consist of three arms connected to a common base and are often used in applications that require high-speed pick and place operations, such as packaging and sorting.

5. Collaborative Robots (Cobots): Unlike traditional industrial robots, cobots are designed to work alongside humans. These robots have built-in sensors and safety features that allow them to operate safely in close proximity to human operators. Cobots are used in a wide range of tasks, including assembly, inspection, and material handling.

Classification of Industrial Robots:

Industrial robots can also be classified based on their functionality and application. Some common classifications include:

1. Material Handling Robots: These robots are primarily used for moving, storing, and retrieving materials within a manufacturing facility. They are often equipped with sensors and vision systems to ensure accurate and efficient handling of materials.

2. Welding Robots: Welding robots are specifically designed for automated welding processes. They can perform complex welding tasks with high precision, consistency, and speed, resulting in improved product quality and reduced production time.

3. Painting Robots: Painting robots are equipped with advanced spray guns and precision control systems, allowing them to apply paint or coatings with high accuracy and uniformity. These robots are extensively used in automotive and aerospace industries.

4. Assembly Robots: Assembly robots are used for assembling parts or components in a production line. They can handle delicate and intricate tasks, ensuring precise and efficient assembly processes.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Link to relevant manufacturer's website]

In conclusion, industrial robots have significantly transformed the manufacturing industry, offering increased productivity, efficiency, and precision. Understanding the different types and classifications of industrial robots is crucial for companies looking to optimize their production processes and stay competitive in today's fast-paced technological landscape.

Thank you for watching this lecture on industrial robots. Stay tuned for the next episode of our YouTube lecture series, where we will explore another exciting technology. Don't forget to subscribe to our channel for more educational content.

Note: This article is available in both English and Hindi. For the Hindi version, please refer to the corresponding video on our YouTube channel. Industrial Robot

Classification and Types of Industrial Robots: A Detailed Overview (Hindi & English)