Skip to content

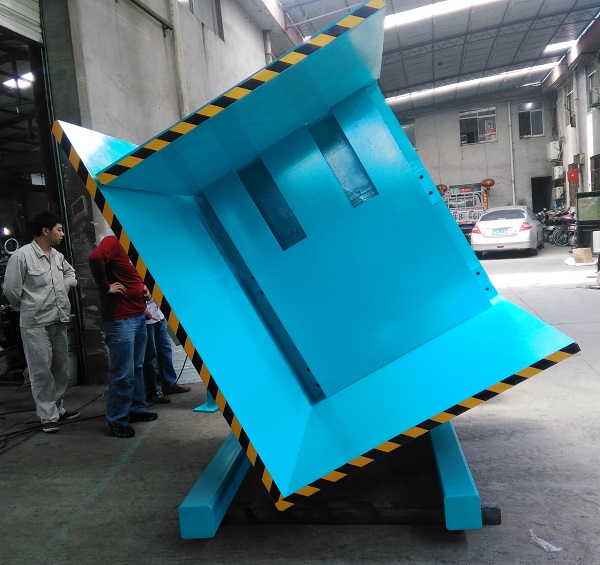

Ground loading pallet inverter

- Dual platen clamping and centralizing the pallet and goods

- Sensors are able to attached to stop clamping automatically, avoid damage to goods

- Floor level design for loading with pallet truck/jack and forklift

- More time are reduced for clamping and capacity grows

- No limit on pallet sizes and weights

- Smooth and stablized strokes

- Easy operation, both local and remote control are chooseable

- Fence is attached for work floor safety

- Specified functions and designs are acceptable

Online pallet inverter

- Rollers on the clamper for automatic loading

- Automatic pallet holding after machine turnover

- Reserved forklift groove for uploading the goods

- Machine works for both large and small pallets

- Different loads are covered

- Stationary movement, a dependable machinery for large warehouse and factory line

- Simplified operation panel with fewer buttons, convenient but functional

- Less defects and responsible aftersales service

- Customization is emphasized and needed for this pallet inverter

Dual clamper pallet inverter

- Double clampers clamping from both up and down directions

- Faster clamping speed and more balanced turnover position

- Large range for different sized pallets

- Maximum capacity depends on cutomer’s needs

- Remote switch is used, the whole operation can be down by just a forklift driver

- Multi-style, both mechanical and hydraulic types are designed to fit client’s actual situation

- Trouble shooting and maintenance are easy for non-skilled workers

- Other customization are allowed to make

Ramp loading pallet inverter

- Two clampers clamping from top and bottom sides

- Low level design with ramp attached for loading with pallet truck or pallet jack

- Mechanical inverter and hydraulic inverter

- No shaking or vibration when machine is turning over

- Heavy load capacity is able to customize

- Machine is stationary and reliable

- Romote and local control are free to switch, easy procedure to continue

- Malfunction is rare to see, fewer wearing parts need to replace

- Protective shield and fence are included

- Suitable equipment for industries such as pharmaceutical manufacturers