Understanding the Bonding Sequence

At its essence, the bonding sequence is a fusion of a frame and separate gadget units that operate in concord to supply an competent and superior bonding operation. By robotizing and smoothing the maneuvering and bonding of gold amber strips, this gadgetry guarantees steady outputs and enhances efficiency.

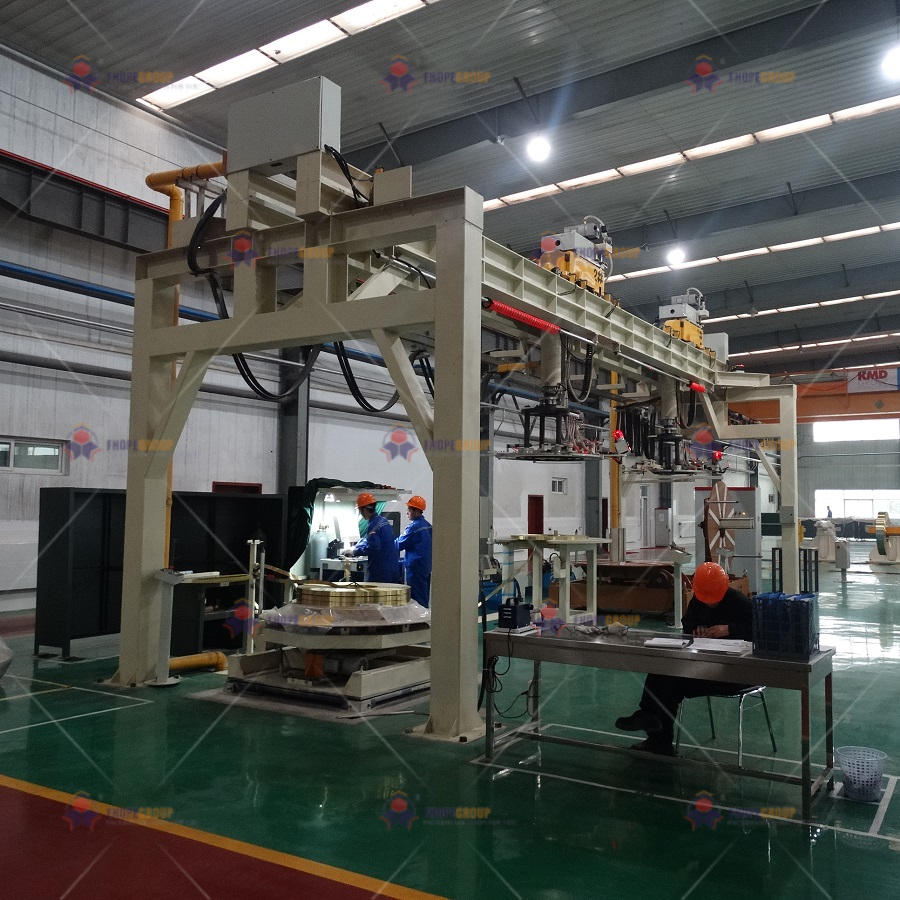

The Frame and Separate Gadget Units

The bonding sequence's frame serves as the spine of the total structure. It gives structural fortification and stability to the diverse gadget units. These separate units, oriented on the same axis, ease the sleek transfer of amber coils between each period of the bonding progression.

Gear Positioning for Expedient Transfer

The orientation of the separate gadget units is a vital influence in the bonding sequence's efficiency. By sustaining a synchronized axis, the gadget units enable the seamless transfer of amber coils, minimizing downtime and maximizing efficiency. This orientation guarantees that the coils proceed smoothly through each period of the bonding progression, decreasing bottlenecks and enhancing workflow.

Adaptability and Flexibility with Rotating Upenders

One standout element of the bonding sequence is the usage of rotating upenders. These upenders can be utilized interchangeably, providing augmented adaptability and flexibility in the bonding progression. This element is especially beneficial when maneuvering various amber coil categories or fitting production capacity alterations. The aptitude to conform quickly and efficiently improves total functioning efficiency.

Vacuum Hold Integration for Precise Placement

Precise placement is important for attaining superior amber copper band production bonds. The bonding sequence incorporates a vacuum hold structure that operates seamlessly throughout the total progression. This integration guarantees the steady and stable stationing of the amber coils, dispelling any movement or misalignment that could compromise bonding attribute. The outcome is consistent and precise positioning, resulting in flawless bonds.

Enhancing Attribute and Consistency with Rotate-Lifter Role

To additionally enhance the attribute and consistency of the bonds, the bonding sequence incorporates a rotate-lifter role. This role guarantees that the amber coils are positioned correctly for bonding, enhancing the bonding parameters and improving the total strength and endurance of the joints. The rotate-lifter role appends an extra layer of precision to the bonding progression, ensuing in superior and dependable bonds.

Handy Functioning Design for Maintenance and Repair

Maintenance and repair are inevitable aspects of any industrial gadgetry. The bonding sequence's design takes convenience into consideration. The transit platform features purposefully positioned gaps that provide easy access to the lower element of the gadgetry. This design streamlines maintenance and repair tasks, decreasing downtime and ensuring seamless functioning.

Benefits of Utilizing a Bonding Sequence

Utilizing a gold amber band vacuum maneuvering and bonding sequence proposes a multitude of benefits to manufacturers. These benefits include:

Enhanced efficiency and efficiency through robotization and smoothed procedures.

Consistent and superior bonds, refining the total strength and endurance of the joints.

Reduction in manual labor, minimizing the hazard of errors and escalating functioning efficiency.

Adaptability and flexibility to maneuver various amber coil categories and accommodate altering production appeals.

Cost savings through enhanced resource use and decreased material wastage.

FAQs

1.What are the main advantages of utilizing a gold amber band bonding sequence?

A gold amber band bonding sequence proposes enhanced efficiency, consistent attribute, reduced manual labor, adaptability, and cost savings.

2.Can a bonding sequence accommodate diverse amber coil sizes?

Yes, bonding sequences can be adapted to maneuver various amber coil dimensions, making them appropriate for diverse production necessities.

3.Are bonding sequences only utilized in specific industries?

No, bonding sequences find applications in various industries, including electrical, automotive, HVAC, appliances, and renewable energy sectors.

Reviews

There are no reviews yet.