If you are looking for a versatile and efficient solution for case packing, then look no further. This robotic case packing work cell combines the benefits of ergonomic hand packing with the convenience of automatic robotic pick and place technology. In this YouTube video, we will explore the features and advantages of this innovative solution.

Case packing is a critical process in many industries, ensuring that products are securely and efficiently packaged for transportation and storage. Traditional methods of case packing often involve manual labor, which can be time-consuming and prone to human error. However, with the integration of robotics, this work cell offers a game-changing solution.

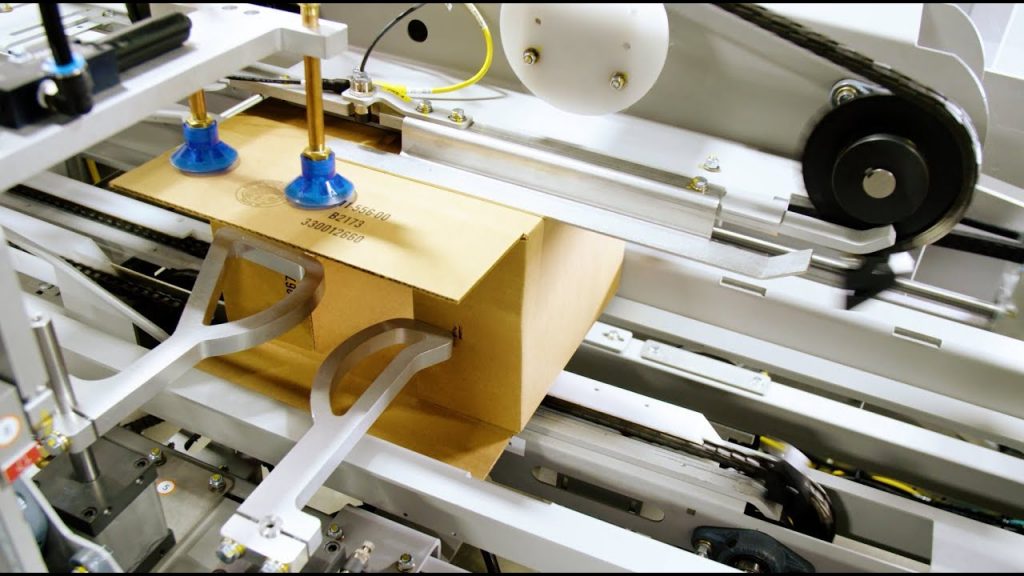

The robotic pick and place technology of this case packing machine allows for precise and efficient handling of products. With its advanced sensors and programming, the robot can accurately identify and pick up items, ensuring they are properly placed in the cases. This eliminates the risk of damage and improves overall productivity.

One of the key benefits of this work cell is its flexibility. It can be easily programmed to handle a wide range of products and packaging configurations. This means that whether you need to pack bottles, cans, boxes, or other items, this machine can adapt to your specific requirements. The flexibility also extends to the size and shape of the cases, allowing for customization based on your needs.

In addition to its flexibility, this robotic case packing work cell offers ergonomic advantages. By combining manual hand packing with robotic assistance, the machine takes into account the comfort and safety of the operator. Tasks that require repetitive motion or heavy lifting can be automated, reducing the risk of injuries and improving the overall working conditions.

The integration of robotics into the case packing process also brings significant efficiency gains. The machine operates at high speeds, ensuring a rapid and continuous flow of products. This not only increases productivity but also allows for better utilization of resources and reduced labor costs.

Furthermore, the robotic pick and place technology provides accurate and consistent packing results. This leads to improved product quality and customer satisfaction. By minimizing errors and ensuring proper packaging, you can enhance your brand reputation and minimize returns or damages during transportation.

In conclusion, this robotic case packing work cell offers a comprehensive solution for efficient and ergonomic case packing. With its advanced robotics technology, it combines the benefits of manual hand packing with the precision and speed of automated pick and place functionality. Whether you are in the food and beverage industry, pharmaceuticals, or any other sector requiring case packing, this machine can cater to your specific needs.

Check out the video to see the case packing machine in action and witness its numerous advantages. Don't miss out on the opportunity to optimize your packaging process and improve your overall operational efficiency. Invest in the leading manufacturer's coil packing solution today!

(Note: The video does not contain any company-specific information or contact details. For more information, please refer to the leading manufacturer's website or contact them directly.) Case Packing Machine

"Efficient Robotic Pick and Place for Case Packing: Streamlining Packaging Processes with Advanced Automation Technology"