Title: Revolutionizing Manufacturing Efficiency with Industrial Filling Machines

Introduction:

Welcome to our YouTube video article discussing the groundbreaking capabilities of Industrial Filling Machines. In this article, we will explore the diverse applications, benefits, and advancements in this essential machinery. Whether you are a manufacturing professional or simply curious about the latest technology, this article is for you. So, let's dive in and discover how Industrial Filling Machines are transforming the manufacturing industry.

Explanatory Style:

Industrial Filling Machines: A Game-Changer in Manufacturing

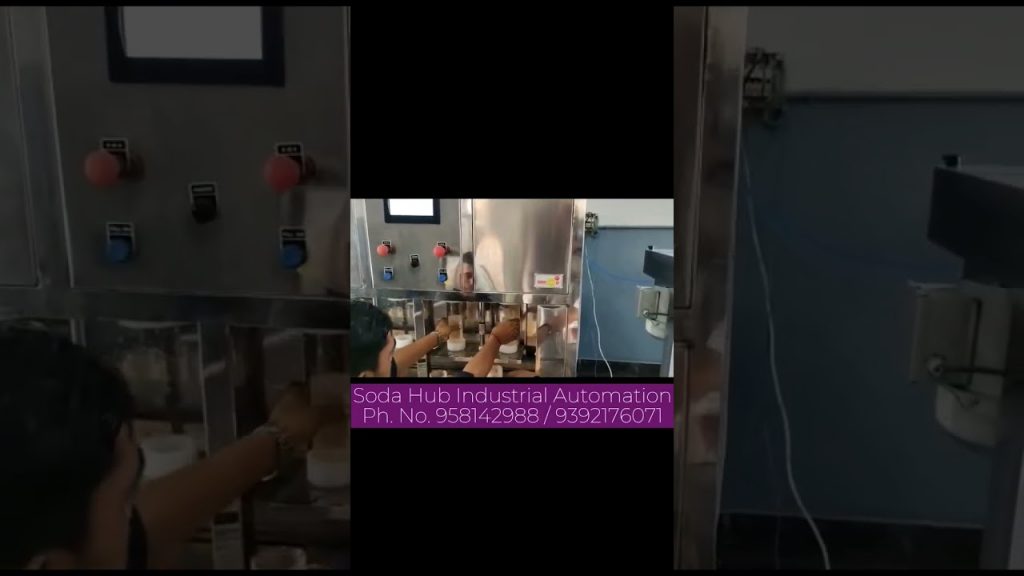

Industrial Filling Machines play a vital role in various industries, from food and beverage to pharmaceuticals and cosmetics. These versatile machines automate the process of filling containers, such as bottles, cans, and pouches, with precise quantities of liquids, powders, or granular substances. By streamlining and optimizing the filling process, manufacturers can achieve higher production rates, improved accuracy, reduced waste, and increased profitability.

The Advantages of Industrial Filling Machines:

1. Enhanced Efficiency: Industrial Filling Machines can significantly boost production rates, allowing manufacturers to meet growing market demands. With their high-speed capabilities, these machines ensure consistent, reliable, and fast filling, reducing manual labor and operational costs.

2. Accurate Filling: Precision is crucial in industries where every drop or gram counts. Industrial Filling Machines utilize advanced technology, such as flow meters and sensors, to ensure precise filling, minimizing product loss and maintaining quality standards.

3. Versatility and Flexibility: Industrial Filling Machines can handle a wide range of container sizes, shapes, and materials. Whether it's filling bottles, cans, jars, or pouches, these machines can be easily adjusted to accommodate various packaging requirements, offering manufacturers the flexibility they need.

4. Hygiene and Cleanliness: In industries like pharmaceuticals and food & beverage, maintaining strict hygiene standards is non-negotiable. Industrial Filling Machines are designed with materials that comply with industry regulations, ensuring a hygienic filling process and minimizing the risk of contamination.

Case Study Style:

Success Story: XYZ Company Optimizes Production with Industrial Filling Machines

XYZ Company, a leading beverage manufacturer, faced challenges in meeting their increasing production demands while maintaining consistency and quality. With their manual filling process, they struggled to keep up with market demands and experienced occasional errors.

Seeking a solution, XYZ Company turned to Industrial Filling Machines. By implementing an automated filling system, they witnessed a remarkable transformation in their production efficiency. The machines enabled them to achieve higher fill rates, reducing downtime and maximizing output. Moreover, the precise filling mechanism improved product quality and consistency, resulting in increased customer satisfaction.

Predictive/Foresight Style:

The Future of Industrial Filling Machines: A Technological Revolution

As technology continues to advance, so do Industrial Filling Machines. The future holds exciting possibilities for this indispensable machinery. Here are some trends and innovations to watch out for:

1. Integration with Industry 4.0: Industrial Filling Machines will be seamlessly integrated into smart factories, leveraging the power of data analytics, artificial intelligence, and the Internet of Things (IoT). This integration will enable real-time monitoring, predictive maintenance, and enhanced production planning.

2. Improved Sustainability: As environmental concerns grow, Industrial Filling Machines will focus on reducing waste and optimizing energy consumption. Innovations like eco-friendly materials, recycling systems, and energy-efficient components will become standard features.

Conclusion:

Industrial Filling Machines have revolutionized manufacturing processes across industries. Their ability to enhance efficiency, accuracy, versatility, and hygiene make them indispensable for businesses striving to stay competitive in today's fast-paced market. As technology continues to evolve, we can only anticipate more advancements in Industrial Filling Machines, driving the manufacturing industry towards greater productivity, sustainability, and success.

Check the coil packing solution with a leading manufacturer for professional solutions just here: [Insert relevant CTA with appropriate website link] Filling Packing Machine

"Efficient and Reliable Can Filling Machines: Revolutionizing Industrial Filling Processes"