Check out the leading manufacturer for professional coil packing solutions here:

Title: Demystifying Plastic Drying: A Comprehensive Guide for Industrial Plastic Injection Machine Operators

Introduction:

In the world of plastic injection molding, understanding the intricacies of plastic drying is essential for ensuring optimal production results. This training course aims to demystify the process of plastic drying by providing a comprehensive explanation of how it is done, how to check drying operations, and how it directly impacts the performance of an industrial plastic injection machine. Whether you are a beginner or an experienced operator, this video will equip you with the knowledge necessary to enhance your plastic drying techniques and improve overall production efficiency.

Keyword: Industrial Plastic Injection Machine

Section 1: Understanding Plastic Drying Technology

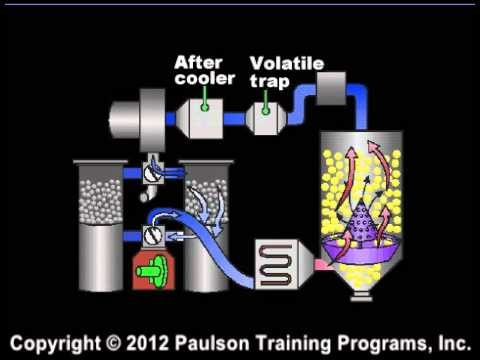

Plastic drying is a critical step in the injection molding process. Without proper drying, moisture can adversely affect the quality of the final product, leading to defects and inconsistencies. This section will delve into the fundamental principles of plastic drying, including the purpose of drying, types of drying methods, and the importance of moisture content control.

Section 2: Checking Drying Operations

To ensure the success of plastic drying, it is crucial to regularly monitor and evaluate the drying operations. In this section, we will explore various techniques and tools that can be utilized to assess the effectiveness of drying, such as moisture analyzers, drying time calculation, and visual inspection methods. By implementing these checks, operators can identify potential issues and make necessary adjustments to optimize drying performance.

Section 3: Best Practices for Plastic Drying

Achieving consistent and efficient plastic drying requires adherence to best practices. This section will discuss key considerations, including proper selection of drying equipment, temperature and airflow control, material-specific drying parameters, and troubleshooting common drying challenges. By following these guidelines, operators can minimize waste, reduce production downtime, and enhance the overall quality of the molded plastic products.

Section 4: Industrial Plastic Injection Machine Integration

Plastic drying technology is closely intertwined with the operation of an industrial plastic injection machine. This section will explore the relationship between plastic drying and the injection molding process, highlighting how effective drying can optimize machine performance, reduce cycle times, and minimize the risk of defects. We will also discuss the integration of drying technology into the injection molding workflow, emphasizing the importance of seamless coordination between these two critical components.

Conclusion:

Plastic drying is an indispensable aspect of the injection molding process. By understanding the principles behind plastic drying, regularly checking drying operations, and implementing best practices, operators can maximize the efficiency and quality of their industrial plastic injection machines. This training course video provides a comprehensive guide for operators at all levels, enabling them to demystify plastic drying and achieve superior production results.

Remember, for professional coil packing solutions, be sure to check out the leading manufacturer mentioned above. Plastic Injection Machine

"Optimizing Plastic Drying Technology for Extrusion and Injection Molding: Enhancing Efficiency in Industrial Plastic Injection Machines"