Title:

"Boost Your Packaging Efficiency with the Cutting-Edge Automatic Packaging Line by FROMM Packaging Australia"

Description:

Introduction:

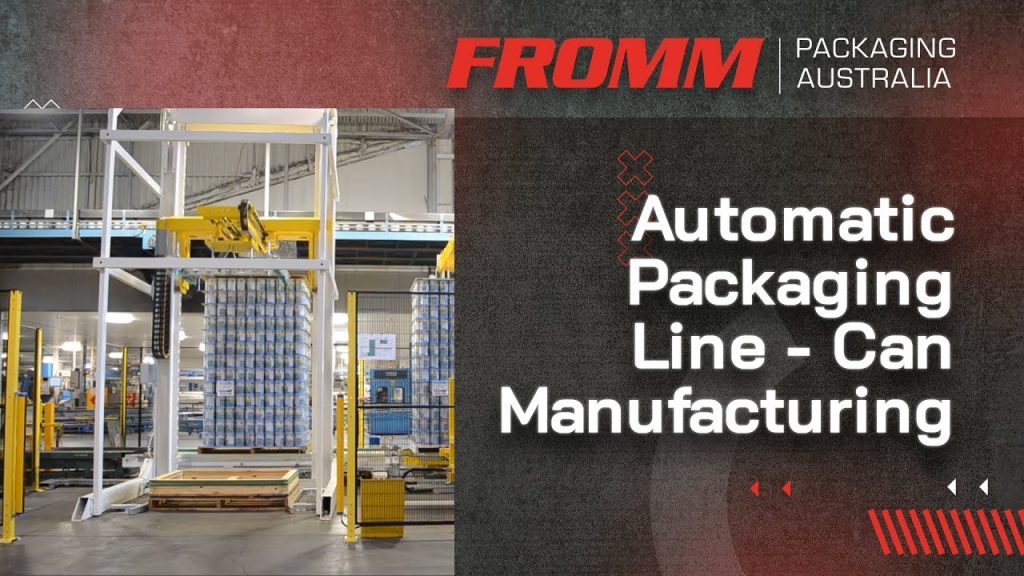

Welcome to our powerful and innovative Automatic Packaging Line, brought to you by FROMM Packaging Australia. As a renowned leader in engineering and manufacturing high-quality strapping and wrapping solutions, we are thrilled to present this video showcasing the exceptional capabilities of our state-of-the-art packaging line. Join us as we delve into the world of can manufacturing and witness how our advanced technology revolutionizes the packaging process.

Video Content:

In this comprehensive video, we will provide you with a detailed overview of our Automatic Packaging Line, highlighting its numerous advantages and features. From enhancing productivity and efficiency to ensuring the utmost safety and quality, our cutting-edge system is designed to meet the diverse packaging needs of various industries.

H1: Unleashing the Potential of the Automatic Packaging Line

Discover how our Automatic Packaging Line can streamline your packaging operations, saving you valuable time and resources. With its automated processes and intelligent control systems, our line ensures consistent and accurate packaging, minimizing errors and maximizing output.

H2: Elevating Can Manufacturing Efficiency

Learn how our Automatic Packaging Line seamlessly integrates into can manufacturing processes, optimizing the packaging of cans with precision and speed. From can loading and alignment to sealing and strapping, our system guarantees a seamless workflow, reducing manual labor and increasing overall efficiency.

H3: Unmatched Quality and Durability

Explore the exceptional quality of our strapping and wrapping solutions, meticulously engineered to withstand the rigors of transportation and storage. Our Automatic Packaging Line offers superior strength and reliability, ensuring your products remain secure and intact throughout their journey.

H3: Innovative Features and Operation Steps

Uncover the innovative features of our Automatic Packaging Line, including user-friendly controls, customizable settings, and advanced sensors for precise packaging. We will guide you through the step-by-step operation process, showcasing how easily our line can be set up and adjusted to meet your specific packaging requirements.

Call to Action:

If you found this video informative and insightful, we encourage you to hit the like button, subscribe to our channel for more industry-leading content, and share this video with your colleagues and friends. Experience the transformative power of our Automatic Packaging Line and revolutionize your packaging operations today.

Additional Tags and Keywords:

Automatic Packaging Line, Packaging Efficiency, Can Manufacturing, FROMM Packaging Australia, Strapping and Wrapping Solutions, Advanced Technology, Streamline Packaging Operations, Consistent Packaging, Can Loading, Sealing and Strapping, Quality and Durability, Innovative Features, Step-by-Step Operation, Increase Efficiency, Improve Productivity.

Hashtags:

#AutomaticPackagingLine #PackagingEfficiency #CanManufacturing #FROMMPackagingAustralia #StrappingandWrappingSolutions #AdvancedTechnology #QualityandDurability #IncreaseEfficiency #StepbyStepOperation #RevolutionizePackaging

Title: Streamlining Efficiency: An Automatic Packaging Line Tilter for Can Manufacturing

Introduction:

In today's fast-paced manufacturing industry, it is crucial to optimize efficiency and productivity. This tilter proposal aims to introduce an automatic packaging line tilter for can manufacturing, offering a solution to enhance the packaging process. By automating the tilting process, this technology will minimize manual labor, reduce production time, and improve overall efficiency.

1. Tilter Technology Overview:

The automatic packaging line tilter is a mechanical device designed to tilt cans during the packaging process. It consists of a conveyor belt system that transports cans to a tilting mechanism, which gently rotates the cans to the desired angle before they are packaged. This technology is integrated into the existing packaging line and can be customized to accommodate various can sizes and specifications.

2. Benefits and Advantages:

a. Increased Efficiency: The tilter reduces the need for manual labor by automating the tilting process, allowing for a faster and more streamlined packaging operation.

b. Enhanced Product Quality: By ensuring precise and controlled tilting, the tilter prevents damage to cans, ensuring that they remain in optimal condition during the packaging process.

c. Time and Cost Savings: With faster production cycles and reduced manual labor, the tilter contributes to overall cost savings and increased profitability.

d. Flexibility and Customization: The tilter can be adjusted to accommodate various can sizes, shapes, and packaging requirements, providing flexibility to adapt to changing market demands.

e. Improved Workplace Safety: By minimizing manual handling of cans, the tilter reduces the risk of injuries associated with repetitive lifting and twisting motions.

3. Integration and Compatibility:

The automatic packaging line tilter is designed to seamlessly integrate into existing can manufacturing and packaging lines. It can be installed at any suitable point in the packaging process, such as after the filling and sealing operations, ensuring compatibility with the existing infrastructure and machinery.

4. Operational Process:

a. Can feeding: Cans are fed onto the conveyor belt system, which transports them to the tilting mechanism.

b. Tilting operation: The tilter gently rotates the cans to the desired angle, which can be adjusted according to the packaging requirements.

c. Packaging: After tilting, the cans are directed to the subsequent packaging stage, where they are boxed, labeled, or palletized as per the production line configuration.

d. Continuous operation: The tilter operates continuously, providing a steady flow of tilted cans for efficient packaging.

Conclusion:

The automatic packaging line tilter for can manufacturing offers an innovative solution to optimize efficiency and productivity in the packaging process. By automating the tilting operation, this technology minimizes manual labor, reduces production time, and ensures the integrity of the cans. With its numerous benefits and compatibility with existing infrastructure, the tilter is an invaluable addition to any can manufacturing facility, enhancing overall productivity and profitability. Automatic Packing Line

#Automatic #Packaging #Line #Manufacturing