Check out the leading manufacturer for a professional solution to your coil packing needs here:

When it comes to manufacturing plastic products, one of the most common processes is injection molding. This technique involves injecting molten plastic into a mold cavity to create the desired shape. While there are many different types of injection molding machines available on the market, today we will focus on a specific type - the DIY plastic injection molding machine.

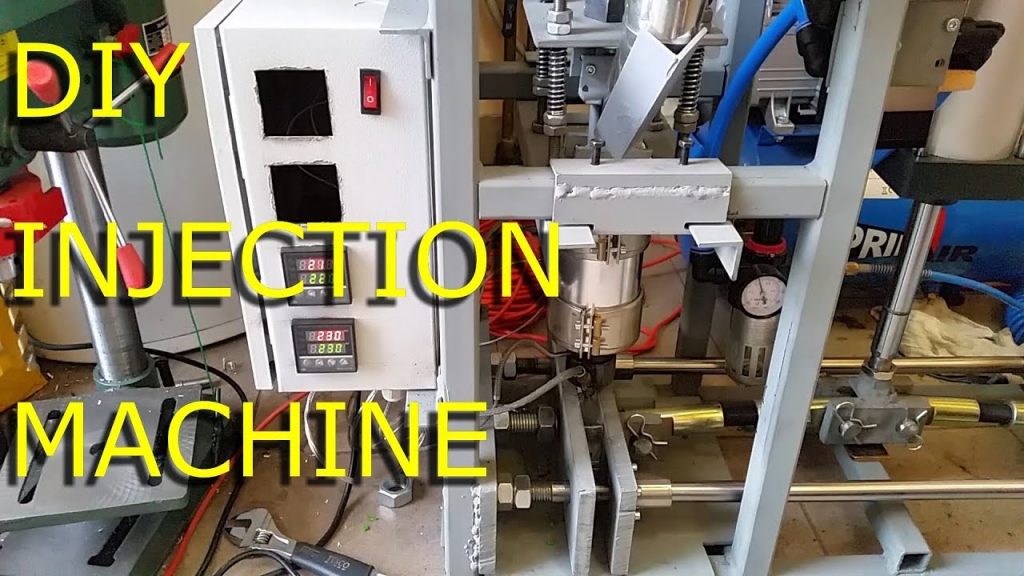

In this YouTube video, we will be testing a DIY plastic injection molding machine that is driven by two air cylinders. The material used for this test is BASF Elastollan TPU, a high-quality thermoplastic polyurethane known for its excellent mechanical properties and durability.

Why is this test important? Well, by conducting this test, we can evaluate the performance and capabilities of the DIY plastic injection molding machine. This information can be helpful for those who are considering building their own injection molding machines or for those who are interested in the DIY approach to manufacturing plastic products.

Now, let's dive into the details of this test. The video will showcase the step-by-step process of setting up the machine, preparing the material, and operating the injection molding process. You will witness how the machine utilizes the power of the air cylinders to inject the molten plastic into the mold cavity, creating the desired product.

Throughout the video, we will provide detailed explanations and insights into the different components of the DIY plastic injection molding machine. From the air cylinders to the heating elements, you will gain a deeper understanding of how these parts work together to achieve the injection molding process.

But why should you care about this DIY approach to plastic injection molding? Well, for starters, building your own machine can be a cost-effective solution, especially for small-scale production or prototyping. It allows you to have control over the manufacturing process and adapt it to your specific needs.

Furthermore, by using a used plastic injection machine, you can save even more money while still achieving high-quality results. These machines have proven their reliability and efficiency over time, making them a practical choice for many manufacturers.

In conclusion, this YouTube video offers an in-depth analysis of a test conducted on a DIY plastic injection molding machine driven by two air cylinders. The use of BASF Elastollan TPU as the test material showcases the machine's capabilities and performance. Whether you are interested in building your own injection molding machine or simply want to learn more about the process, this video provides valuable insights and information.

So, if you're ready to explore the world of DIY plastic injection molding machines and learn more about the benefits of using a used plastic injection machine, make sure to check out this informative video. It will equip you with the knowledge you need to make informed decisions and take your plastic manufacturing endeavors to the next level.

Remember, for a professional solution to your coil packing needs, check out the leading manufacturer mentioned above. They have the expertise and experience to provide you with the best packaging solution for your specific requirements. Plastic Injection Machine

"Testing a DIY Plastic Injection Molding Machine and Reviewing a Used Injection Machine"