Title: Orbital Stretch Wrapper - The Ultimate Solution for Efficient Pallet Wrapping

Description:

Welcome to our informative video on the revolutionary Orbital Stretch Wrapper and its role in pallet wrapping using stretch film machines. In this comprehensive guide, we will provide you with a detailed overview of the Orbital Stretch Wrapper, explain what a stretch film machine is, and highlight key points about stretch film machines and their pallet wrapping capabilities.

Introduction:

In this video, we delve into the world of efficient pallet wrapping with the remarkable Orbital Stretch Wrapper. Discover how this cutting-edge technology simplifies and streamlines the process of wrapping pallets of products with stretch film, also known as pallet wrapping. Whether you are a warehouse manager, logistics professional, or simply curious about the latest advancements in packaging, this video is tailored for you.

Video Content:

1. What is an Orbital Stretch Wrapper:

- Uncover the concept and functionality of the Orbital Stretch Wrapper.

- Explore how it optimizes pallet wrapping efficiency and ensures product stability during transportation.

- Learn about the various components and features that make the Orbital Stretch Wrapper a game-changer in the industry.

2. Understanding Stretch Film Machines:

- Gain insights into the purpose and benefits of stretch film machines.

- Discover how stretch film machines contribute to secure pallet wrapping and prevent product damage.

- Learn about the different types and configurations of stretch film machines available.

3. Key Points about Stretch Film Machines:

- Delve into the specifics of using stretch film machines for pallet wrapping.

- Explore the advantages of utilizing stretch film machines in terms of cost savings, labor efficiency, and load stability.

- Understand the importance of selecting the right stretch film machine for your specific packaging needs.

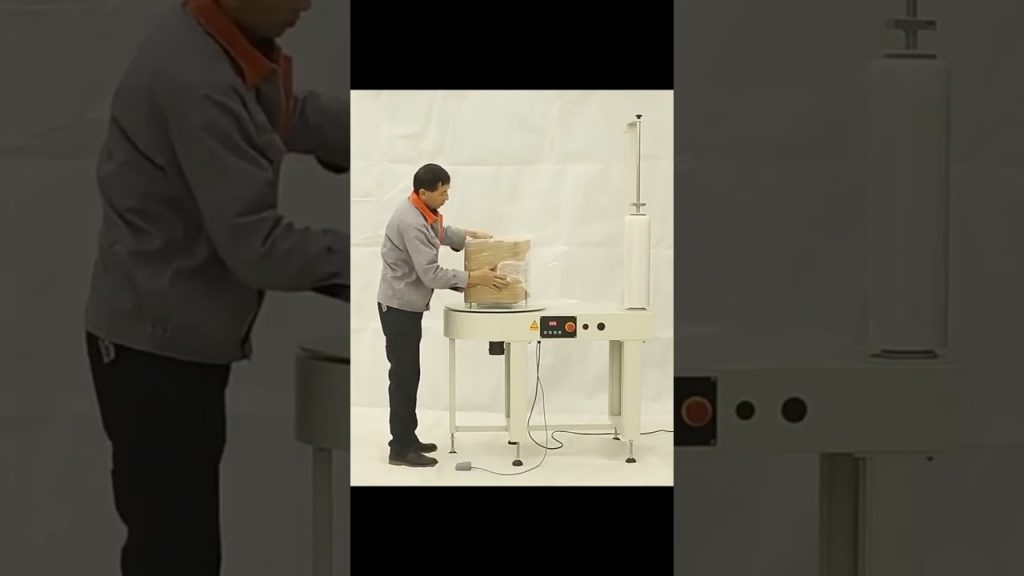

4. Operation Steps:

- Step-by-step breakdown of the operational process involved in using a stretch film machine for pallet wrapping.

- Detailed instructions on how to set up, load, and operate the Orbital Stretch Wrapper effectively.

- Expert tips and best practices for ensuring optimal results and maximizing efficiency.

Call to Action:

If you found this video informative and valuable, don't forget to hit the like button, subscribe to our channel for more insightful content, and share this video with others who may benefit from learning about the Orbital Stretch Wrapper and stretch film machines. Feel free to leave any questions or comments below, and we'll be delighted to engage with you.

Additional Tags and Keywords:

Orbital Stretch Wrapper, stretch film machine, pallet wrapping, packaging technology, efficient pallet wrapping, stretch film machines benefits, secure load stability, cost-effective packaging, labor efficiency, packaging solutions, pallet wrapping process, logistics optimization, stretch film configuration, operational guide.

Hashtags:

#OrbitalStretchWrapper #StretchFilmMachine #PalletWrapping #PackagingTechnology #EfficientWrapping #LogisticsOptimization #SecureLoadStability #PackagingSolutions #OperationalGuide

A tilter for "What is stretch film machine":

Stretch film machines, also referred to as stretch wrap machines, are automated devices designed to efficiently wrap pallets or large objects with stretch film. These machines provide a secure and tight packaging solution for transportation and storage purposes.

The main function of a stretch film machine is to stretch the film around the object, creating tension and securing the load. This is done by rotating the object on a turntable or conveyor while the film is dispensed from a roll. The film is stretched as it passes through various components of the machine, including rollers, tensioning devices, and pre-stretch units.

The tilter in a stretch film machine plays a crucial role in the wrapping process. It is responsible for tilting the object, allowing the machine to wrap the film around all sides of the load. This is especially important for irregularly shaped objects or those with protruding parts.

The tilter operates by using hydraulic, pneumatic, or electric systems to tilt the object to a certain angle. This can be adjusted according to the specific requirements of the load. Once the object is tilted, the stretch film machine continues to wrap the film around the load, ensuring it is tightly secured from all angles.

The tilter in a stretch film machine enhances the efficiency and effectiveness of the wrapping process. It ensures that the film reaches all sides of the load, providing maximum stability and protection. This is particularly useful in industries such as logistics, warehousing, and manufacturing, where the safe transportation of goods is of utmost importance.

In conclusion, a tilter is an integral component of a stretch film machine. Its purpose is to tilt the object, enabling the machine to wrap the stretch film around all sides of the load. This enhances the efficiency and effectiveness of the wrapping process, ensuring maximum stability and protection during transportation and storage.Orbital Stretch Wrapper

#stretch #film #machine