Looking for a reliable and efficient strapping machine? Look no further! In this YouTube video article, we will discuss everything you need to know about strapping machines, their prices, and how to use a pneumatic strapping tool.

Strapping machines are essential equipment for various industries, including packaging, logistics, and manufacturing. They help secure packages, bundles, and pallet loads, ensuring safe transportation and storage. If you are in the market for a strapping machine, it is crucial to understand its price range and functionality to make an informed decision.

First, let's dive into the topic of strapping machine prices. The cost of a strapping machine can vary depending on several factors, including its type, model, features, and brand. Typically, strapping machines can range from $500 to $1000, providing you with various options to choose from based on your budget and requirements. It is important to note that investing in a high-quality strapping machine can greatly improve efficiency and save costs in the long run.

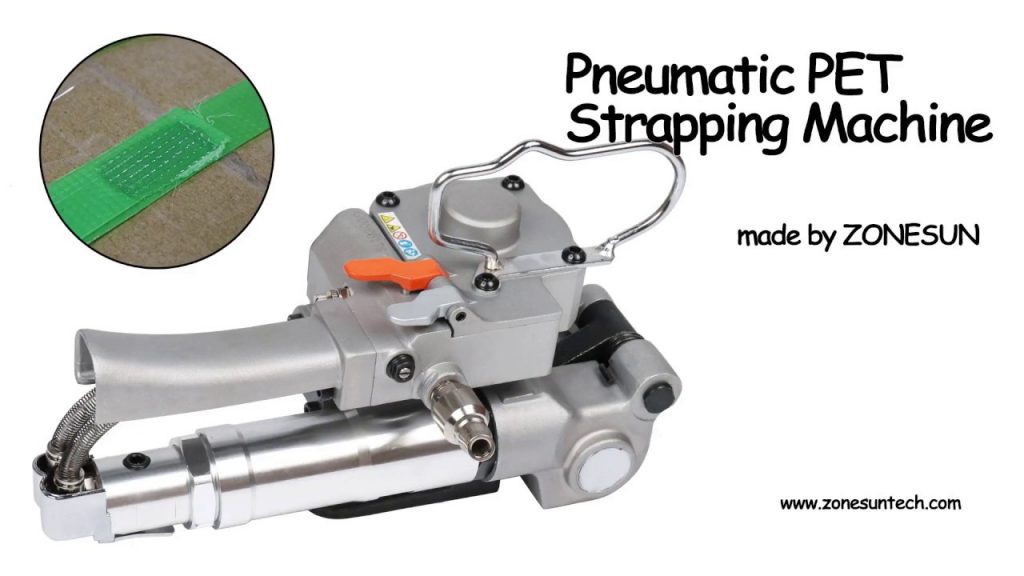

Now, let's move on to understanding how to use a pneumatic strapping tool, which is a popular type of strapping machine. Pneumatic strapping machines utilize compressed air to tension and seal straps quickly and effectively. The process involves a few simple steps:

1. Prepare the strapping material: Choose the appropriate strapping material, whether it's plastic, polyester, or steel. Ensure that the strapping material is of the correct width and thickness for your application.

2. Load the strapping material: Load the strapping material onto the dispenser or strapping machine, ensuring it is properly threaded through the machine's guides and tensioning system.

3. Position the package: Position the package or bundle that needs to be strapped securely. Make sure it is properly aligned and organized to ensure a tight and stable strap.

4. Tension the strap: Activate the pneumatic strapping machine by pressing the appropriate button or trigger. The machine will automatically tension the strap around the package, providing the desired level of tightness.

5. Seal the strap: Once the strap is tensioned, the pneumatic strapping tool will seal the strap using heat or friction welding, depending on the machine's mechanism. This creates a strong and secure seal.

6. Trim the excess strap: After sealing the strap, trim any excess material using a strap cutter or scissors, ensuring a neat and professional finish.

Using a pneumatic strapping tool offers numerous advantages, including speed, efficiency, and consistent tensioning. It is an excellent choice for industries that require high-volume strapping operations.

In conclusion, strapping machines are crucial equipment for securing packages and bundles during transportation and storage. When considering a strapping machine, it is essential to understand its price range, features, and functionality. Additionally, knowing how to use a pneumatic strapping tool can greatly enhance your strapping process.

So, if you are looking for a reliable and professional strapping machine solution, look no further! Check out leading manufacturers in the market who offer a wide range of strapping machines at competitive prices. Their expertise and quality products will ensure you find the perfect strapping machine for your specific needs.

Check the coil packing solution with a leading manufacturer for a professional solution just here: [Link to the leading manufacturer's website]

Remember, investing in a high-quality strapping machine is a long-term investment that will not only improve your packaging process but also save costs and ensure customer satisfaction. Strapping Machines

"Mastering the Pneumatic Strapping Tool: A Comprehensive Guide to Efficient Strapping with the Pneumatic Strapping Machine at an Affordable Price"