Check out the leading manufacturer for professional solutions in coil packing: [company name].

Title: Automation in the Automotive Industry: Revolutionizing Production Lines with Industrial Robotic Arms

Introduction:

In today's fast-paced world, the automotive industry is constantly evolving to meet the demands of consumers. One of the key drivers of this evolution is automation, which has transformed the manufacturing processes and production lines. Industrial robotic arms have become an indispensable tool in the automotive industry, revolutionizing the way cars are built. In this article, we will explore the role of industrial robotic arms in the automotive industry and how they have reshaped the production lines.

Explanatory Style:

1. What are Industrial Robotic Arms?

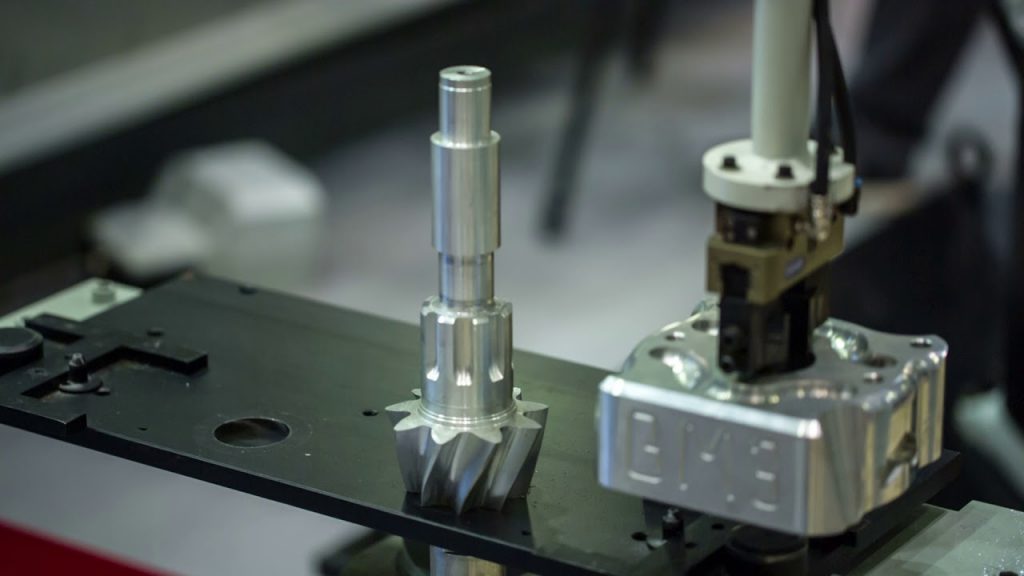

Industrial robotic arms, also known as robotic manipulators, are highly advanced machines designed to perform tasks with precision, speed, and accuracy. These robotic arms consist of multiple joints and links that mimic the movements of human arms, allowing them to perform a wide range of activities. Equipped with sensors, actuators, and controllers, these robotic arms can be programmed to perform complex tasks autonomously.

2. Industrial Robotic Arms in the Automotive Industry:

The automotive industry has embraced automation to enhance efficiency, productivity, and quality control. Industrial robotic arms have played a pivotal role in this transformation. These robotic arms are utilized in various stages of the production line, from assembling parts to painting and welding car bodies.

3. Streamlining Production Lines:

By integrating industrial robotic arms into the production lines, automakers have achieved significant improvements in efficiency and productivity. These robotic arms can perform repetitive tasks with consistent precision, eliminating human errors and reducing the risk of accidents. Moreover, they can work continuously without breaks, ensuring uninterrupted production.

4. Enhancing Quality Control:

Industrial robotic arms have revolutionized quality control in the automotive industry. Equipped with advanced sensors and cameras, these robotic arms can inspect parts and components at a microscopic level, detecting even the smallest defects. This ensures that only flawless products reach the market, enhancing customer satisfaction and brand reputation.

5. Increased Flexibility:

Industrial robotic arms offer unparalleled flexibility in the production lines. They can be easily reprogrammed and reconfigured to adapt to new product designs and specifications. This enables automakers to quickly respond to market demands and produce a wide range of vehicle models without significant retooling or reconfiguration.

6. Collaborative Robots:

Collaborative robots, or cobots, are a recent development in the field of industrial robotics. These robots are designed to work alongside human operators, enhancing productivity and safety. In the automotive industry, cobots are often used for tasks that require human dexterity and decision-making, while the heavy lifting and repetitive tasks are handled by the industrial robotic arms.

Conclusion:

Industrial robotic arms have transformed the automotive industry, revolutionizing the production lines and enhancing efficiency, productivity, and quality control. These advanced machines have streamlined the manufacturing processes, ensuring faster production, higher precision, and improved product quality. As the automotive industry continues to evolve, industrial robotic arms will play an increasingly crucial role in shaping the future of car manufacturing.

Check out the leading manufacturer for professional solutions in coil packing: [company name]. Industrial Robot

"Optimizing Efficiency: Streamlining Robotic Arm Production Lines in the Automotive Industry"