Title: The Ultimate Guide to Industrial Packing Line: Highly Automated Packaging and Palletizing for Efficient Material Workflow

Description:

Introduction:

Welcome to our comprehensive guide on Industrial Packing Line – a highly automated packaging and palletizing solution that ensures an efficient material workflow while providing a compact line. In this video, we will explore the key features, benefits, and operation steps of this innovative system.

Video Content:

1. Understanding Industrial Packing Line:

- Discover the concept behind Industrial Packing Line and how it revolutionizes the packaging industry.

- Learn about its advanced automation capabilities and how it streamlines the packaging process.

2. Key Features of Highly Automated Packaging and Palletizing Line:

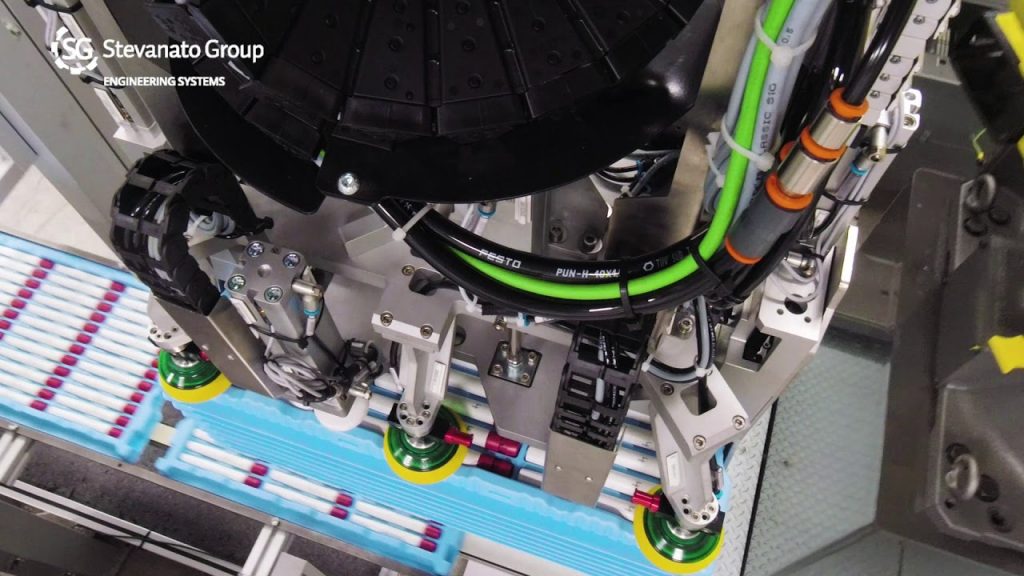

- Explore the various components and machinery involved in the packing line, including conveyors, robotic arms, and packaging equipment.

- Understand how these components work seamlessly together to optimize the packaging process, improving efficiency and productivity.

3. Ensuring Product Integrity:

- Discover how the Industrial Packing Line takes care of your products throughout the packaging journey until the final packaging stage.

- Learn about the measures implemented to ensure product integrity, including quality control checks and monitoring systems.

4. Operation Steps:

- Step-by-step guide on how to operate the Industrial Packing Line, from initial setup to final packaging.

- Gain insights into the programming and customization options available to tailor the system to specific product requirements.

5. Benefits of Industrial Packing Line:

- Explore the advantages of implementing a highly automated packaging and palletizing line, such as increased productivity, reduced labor costs, and improved product consistency.

- Understand how the compact design of the system optimizes floor space utilization without compromising performance.

Call to Action:

If you found this video informative and insightful, don't forget to hit the like button, subscribe to our channel for more industry-related content, and share this video with others who might benefit from it.

Additional Tags and Keywords:

Industrial packing, automated packaging, palletizing line, efficient material workflow, compact line, packaging process, product integrity, productivity, customization options.

Hashtags:

#IndustrialPackingLine #AutomatedPackaging #EfficientMaterialWorkflow #PalletizingLine #ProductIntegrity

Here's a tilter for a Highly Automated Packaging and Palletizing Line:

Title: Highly Automated Packaging and Palletizing Line Tilter

Introduction:

In a highly automated packaging and palletizing line, the tilter plays a crucial role in optimizing the packaging and palletizing process. This tilter is designed to efficiently handle and rotate products, ensuring they are properly positioned for packaging and palletizing. By automating this task, the tilter enhances productivity, reduces labor costs, and improves overall efficiency. This article will discuss the key features and benefits of the Highly Automated Packaging and Palletizing Line Tilter.

1. Automated Rotation:

The tilter incorporates advanced automation technology to rotate products in the desired orientation. With precise control and adjustable settings, it can rotate products at different angles to ensure proper packaging and palletizing. This automation eliminates the need for manual handling, reducing the risk of injuries and improving operational safety.

2. Versatile Handling:

The tilter is designed to handle various types of products, including boxes, bags, containers, and more. Its adjustable gripping mechanism securely holds the products during rotation, preventing any damage or slipping. The versatility of the tilter allows it to accommodate different shapes, sizes, and weights of products, making it suitable for a wide range of industries.

3. Integration with Packaging and Palletizing Systems:

The tilter seamlessly integrates with the packaging and palletizing systems in the production line. It is equipped with sensors and interfaces that enable communication and synchronization with other automated machinery. This integration ensures smooth operation and eliminates bottlenecks, maximizing throughput and minimizing downtime.

4. Precise Positioning:

With its accurate positioning capabilities, the tilter ensures that products are precisely aligned before packaging and palletizing. This feature improves the quality of packaging, enhances stackability, and reduces the risk of product damage during transportation. The precise positioning also optimizes space utilization on pallets, increasing the number of products that can be stacked efficiently.

5. User-Friendly Interface:

The tilter features a user-friendly interface that allows operators to easily control and monitor its functions. The interface provides real-time feedback on rotation angles, status, and alarms, enabling operators to make necessary adjustments quickly. Intuitive controls and visual indicators simplify operation and reduce the learning curve for new users.

6. Maintenance and Safety:

The tilter is designed for minimal maintenance requirements, ensuring continuous operation and reducing downtime. It is equipped with safety features such as emergency stop buttons, safety interlocks, and overload protection systems. These safety measures protect both operators and products, ensuring a safe working environment.

Conclusion:

The Highly Automated Packaging and Palletizing Line Tilter is an essential component in optimizing the packaging and palletizing process. Its automated rotation, versatile handling, integration capabilities, precise positioning, user-friendly interface, and maintenance and safety features make it a valuable asset in highly automated production lines. By incorporating this tilter, businesses can enhance productivity, reduce costs, and improve overall efficiency in their packaging and palletizing operations. Automatic Packing Line

#Highly #automated #packaging #palletizing #line