Check out our website for more information on Industrial Robot Programming and how it can revolutionize your manufacturing process."

In the Laboratory for Computational Sensing and Robotics at Johns Hopkins University, our team of talented researchers and engineers have been hard at work developing a groundbreaking prototype system for Industrial Robot Programming. This innovative technology has the potential to transform the way industrial robots are programmed and operated, making them more efficient, flexible, and user-friendly than ever before.

Industrial robots have long been a vital part of the manufacturing industry, performing repetitive tasks with precision and speed. However, programming these robots has traditionally been a complex and time-consuming process, requiring specialized knowledge and skills. With our prototype system, we aim to simplify and streamline this process, making it accessible to a wider range of users.

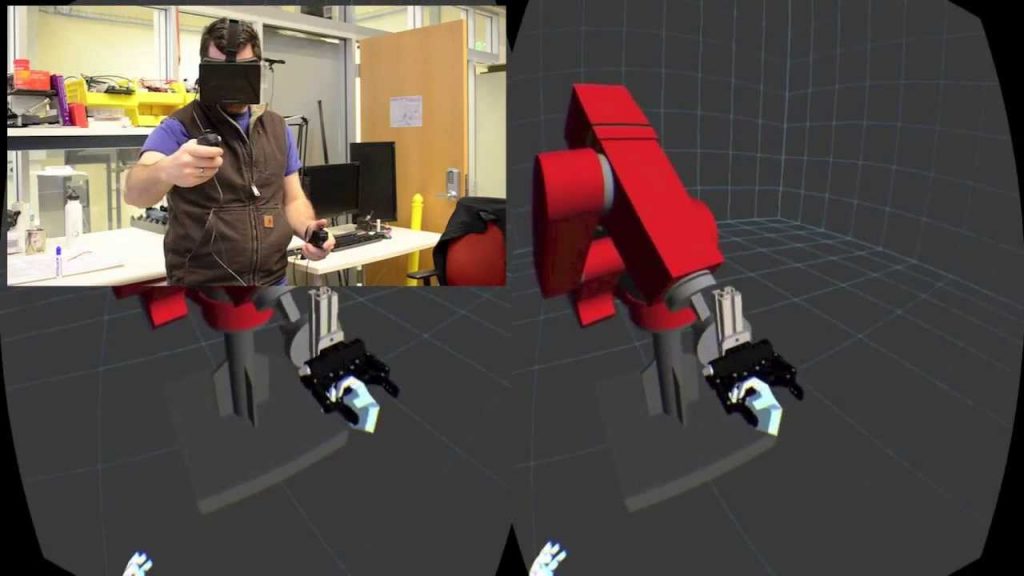

One of the key features of our system is its integration with the Oculus Rift, a virtual reality headset. By using this cutting-edge technology, operators can immerse themselves in a virtual environment and interact with the robot as if they were right there in the factory. This not only enhances the user experience but also allows for more intuitive and natural robot programming.

To demonstrate the capabilities of our prototype system, we conducted a case study with a leading manufacturer in the industry. The manufacturer was facing challenges in programming their industrial robot to handle a variety of tasks efficiently and accurately. By implementing our system, they were able to significantly reduce programming time and improve overall productivity.

In addition to its ease of use, our system offers advanced programming features that enable users to optimize robot performance. Through the use of algorithms and machine learning, the system can analyze and adapt to different manufacturing environments, making real-time adjustments to ensure optimal efficiency and quality.

The potential applications of Industrial Robot Programming are vast and diverse. From automotive assembly lines to food packaging, this technology has the power to revolutionize various industries. By automating repetitive tasks and increasing production efficiency, manufacturers can reduce costs, improve product quality, and ultimately gain a competitive edge in the market.

As we look to the future, we envision a world where Industrial Robot Programming is the norm rather than the exception. With advancements in technology and the increasing demand for automation, this field is poised for significant growth. By staying at the forefront of research and development, we aim to continue pushing the boundaries of what is possible in industrial robotics.

In conclusion, our prototype system for Industrial Robot Programming is a game-changer in the manufacturing industry. With its user-friendly interface, advanced programming features, and integration with virtual reality technology, it has the potential to revolutionize the way industrial robots are programmed and operated. By embracing this technology, manufacturers can unlock new levels of efficiency, productivity, and competitiveness. Check out our website for more information on Industrial Robot Programming and how it can transform your manufacturing process.

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert website link]. Industrial Robot

"Revolutionizing Industrial Robot Programming: Immersive Oculus Rift Integration Unlocks New Possibilities"