Check out our website for more details on how to contact us: www.haloblaze.com. We are excited to introduce our Heat Shrinking Machine, an innovative solution for heat shrink tube applications. In this article, we will provide an in-depth analysis of the MTP-4 Heavy Duty XL Heat Shrinking Machine and its features. Whether you are a sales engineer or simply interested in learning more about this technology, this article is for you.

Heat Shrinking Machine: An Overview

Heat shrinking machines are widely used in various industries for packaging and sealing purposes. They utilize heat to shrink plastic films or tubes around a product, providing a secure and protective wrap. This process not only enhances the product's appearance but also ensures its integrity during transportation and storage.

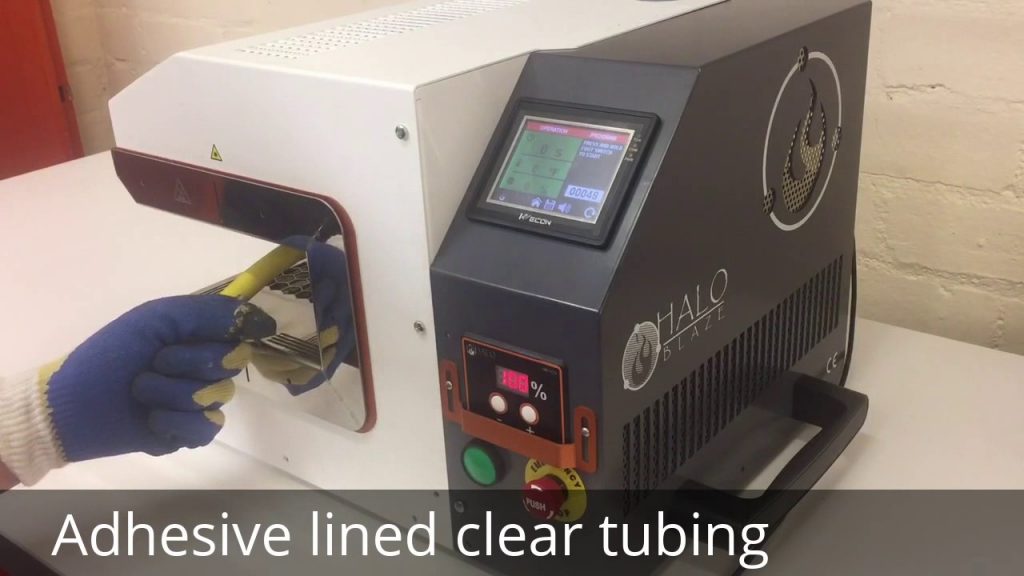

Introducing the MTP-4 Heavy Duty XL Heat Shrinking Machine

The MTP-4 Heavy Duty XL Heat Shrinking Machine is a high-performance solution designed for heat shrink tube applications. Its advanced features make it suitable for a wide range of industries, including manufacturing, logistics, and electronics.

Key Features of the MTP-4 Heavy Duty XL Heat Shrinking Machine

1. Robust Construction: The machine is built to withstand heavy-duty usage, ensuring durability and longevity.

2. Adjustable Conveyor Speed: Users can easily adjust the conveyor speed to match their specific requirements, improving efficiency and productivity.

3. Precise Temperature Control: The machine offers precise temperature control, allowing users to achieve optimal shrink results consistently.

4. User-Friendly Interface: With an intuitive interface, the MTP-4 Heavy Duty XL Heat Shrinking Machine is easy to operate, minimizing the learning curve for users.

5. Versatile Application: This machine can handle various heat shrink tube sizes, making it a versatile solution for different packaging needs.

Benefits of Using the MTP-4 Heavy Duty XL Heat Shrinking Machine

1. Enhanced Product Presentation: The heat shrinking process adds a professional touch to the product, enhancing its visual appeal.

2. Improved Protection: By tightly wrapping the product, the machine provides an additional layer of protection against dust, moisture, and other external factors.

3. Time and Cost Efficiency: With adjustable conveyor speed and precise temperature control, the machine optimizes production time and reduces material waste, resulting in cost savings for businesses.

4. Increased Productivity: The user-friendly interface and versatile application of the machine contribute to increased productivity and streamlined operations.

5. Reliable Performance: The robust construction of the machine ensures reliable and consistent performance, minimizing downtime.

In Conclusion

The MTP-4 Heavy Duty XL Heat Shrinking Machine is a game-changer in the heat shrink tube industry. Its advanced features, user-friendly interface, and versatile application make it a top choice for businesses across various sectors. Whether you are packaging electronic components, industrial goods, or consumer products, this machine guarantees superior shrink results and improved product presentation.

Check out our website for more information on the MTP-4 Heavy Duty XL Heat Shrinking Machine and other innovative solutions. We are committed to providing the best coil packing solutions to meet your specific needs. Visit our website today and discover how our products can revolutionize your packaging process. Shrinking Machine

"Heat Shrink Tube Applications Simplified: Discover the MTP-4 Heavy Duty XL Heat Shrinking Machine"