Title: Ultimate Automatic Handling Machine for Composite LPG Tanks | Mikrosam Automated Line

Description:

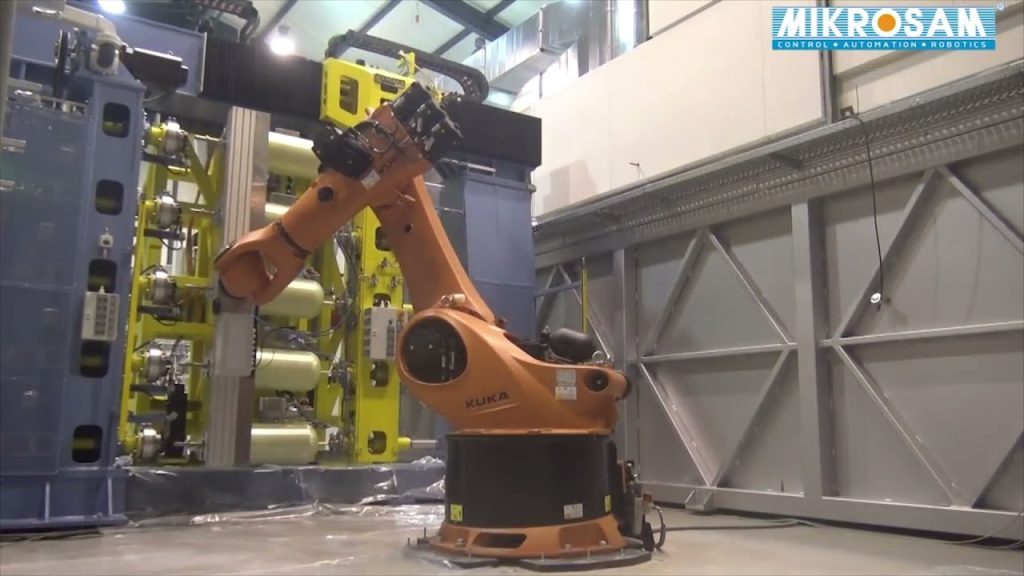

Welcome to the world of cutting-edge technology in composite LPG tank production! Discover the revolutionary Automatic Handling Machine by Mikrosam, designed to streamline the manufacturing process of composite LPG tanks. With advanced filament winding, handling, and curing capabilities, this automated line takes efficiency and precision to new heights!

As the demand for composite LPG cylinders continues to rise, it is crucial to stay ahead of the curve. This comprehensive video showcases the Mikrosam Automated Line, offering an in-depth exploration of its features, benefits, and operational steps. Join us as we delve into the world of composite LPG tank production and witness the possibilities this technology offers.

[Heading 1: Introduction]

In this video, we present the game-changing Automatic Handling Machine by Mikrosam, catering to the escalating demand for composite LPG tanks. Explore the power of automation and witness how this cutting-edge solution revolutionizes the manufacturing process.

[Heading 2: Video Content]

1. Filament Winding: Uncover the secrets of precise filament winding, allowing for superior strength and durability in composite LPG tanks. Witness the advanced machinery at work and understand the intricate process behind this essential manufacturing step.

2. Handling & Curing: Dive into the world of seamless handling and curing, ensuring optimal quality and consistency in every composite LPG tank produced. Discover how the Mikrosam Automated Line simplifies complex tasks, minimizing human intervention and maximizing efficiency.

3. Automated Filament Winding Lines: Witness the power of automation as we explore the automated filament winding lines incorporated in this revolutionary system. Experience unmatched precision and speed, resulting in enhanced productivity and reduced manufacturing time.

[Heading 3: Key Highlights]

- Unparalleled efficiency and accuracy in composite LPG tank production

- State-of-the-art filament winding technology

- Streamlined handling and curing processes

- Advanced automation for increased productivity

- Superior strength and durability of composite LPG tanks

[Heading 4: Call to Action]

If you found this video informative and inspiring, don't forget to hit the like button and subscribe to our channel for more exciting content on advanced manufacturing technologies. Share this video with fellow enthusiasts to spread the word about the Mikrosam Automated Line and its game-changing capabilities.

Additional Tags and Keywords: #AutomatedHandlingMachine #CompositeLPGTanks #MikrosamAutomatedLine #FilamentWinding #HandlingandCuring #AutomationInManufacturing

Hashtags: #CompositeLPG #AutomatedProduction #ManufacturingTechnology #EfficiencyInProduction #AdvancedHandlingMachine

Title: Mikrosam Automated Line Tilter for Composite LPG Tanks: Enhancing Filament Winding, Handling, and Curing Processes

Introduction:

Composite LPG tanks have gained significant popularity due to their lightweight, corrosion resistance, and high strength-to-weight ratio properties. To meet the growing demand for such tanks, Mikrosam introduces an innovative automated line tilter solution designed to optimize the filament winding, handling, and curing processes. This tilter aims to enhance productivity, reduce manual labor, improve quality control, and ensure the safe production of composite LPG tanks.

1. Improved Filament Winding:

The Mikrosam Automated Line Tilter streamlines the filament winding process by providing precise control over the winding angle and tension. This results in consistent fiber placement, minimizing fiber overlaps and voids within the tank structure. The tilter's advanced software allows for easy programming of winding patterns, ensuring optimal fiber orientation for enhanced mechanical properties and structural integrity.

2. Enhanced Handling Capabilities:

With its automated handling system, the tilter eliminates the need for manual material handling, reducing the risk of operator errors and fatigue. The tank molds can be automatically loaded and unloaded onto the tilter, streamlining the production line and minimizing downtime. The tilter's ergonomic design facilitates easy and safe access to the tanks during the handling process, further improving operational efficiency.

3. Efficient Curing Process:

The Mikrosam Automated Line Tilter incorporates an advanced curing system that ensures uniform heat distribution and precise temperature control throughout the tank. This results in consistent curing of the composite material, reducing the risk of delamination, voids, and other defects. The tilter's integrated monitoring system continuously monitors the curing process, enabling real-time adjustments to optimize curing parameters and ensure high-quality tank production.

4. Quality Control and Data Logging:

To ensure compliance with industry standards, the tilter is equipped with a comprehensive quality control system. This system performs real-time monitoring of critical parameters, such as winding tension, fiber placement, and curing temperature. Any deviations from the set specifications are flagged, and immediate corrective actions can be taken. Furthermore, the tilter automatically logs all relevant data, providing traceability and facilitating quality assurance audits.

5. Safety Features:

The Mikrosam Automated Line Tilter prioritizes operator safety with its robust safety features. These include safety interlocks, emergency stop buttons, and automated alarms for abnormal conditions. The tilter's design also minimizes physical strain on operators by reducing the need for manual lifting and repetitive motions.

Conclusion:

The Mikrosam Automated Line Tilter revolutionizes the production of composite LPG tanks by optimizing filament winding, handling, and curing processes. This advanced solution enhances productivity, ensures consistent quality, and improves workplace safety. With its precise control, automated handling, efficient curing, and comprehensive quality control system, the tilter sets a new standard for the composite LPG tank manufacturing industry.Handling Machine

#Mikrosam #Automated #Line #Composite #LPG #Tanks #Filament #Winding #Handling #Curing