Check the coil packing solution with leading manufacturer for the professional solution just here: [Link to the manufacturer's website]

Title: How to Produce Sports Water Bottles using Injection Blow Molding Machine (IBM) with Automatic Labeling Machine

Introduction:

In today's fast-paced world, staying hydrated is essential, especially for athletes and sports enthusiasts. And what better way to quench your thirst than with a sports water bottle? These bottles not only keep your drink cool but also offer convenience on the go. Have you ever wondered how these bottles are made? In this article, we will explore the process of producing sports water bottles using the Injection Blow Molding Machine (IBM) and the role of an Automatic Labeling Machine in the production line.

I. Understanding Injection Blow Molding Machine (IBM):

The Injection Blow Molding Machine (IBM) is a versatile manufacturing tool used to produce hollow plastic parts, including sports water bottles. The machine consists of three main components: the injection unit, the mold, and the blow molding unit. The process begins with the injection unit melting plastic resin and injecting it into a preform mold, creating a hollow tube called a preform. The preform is then transferred to the blow molding unit, where it is inflated and molded into the desired shape.

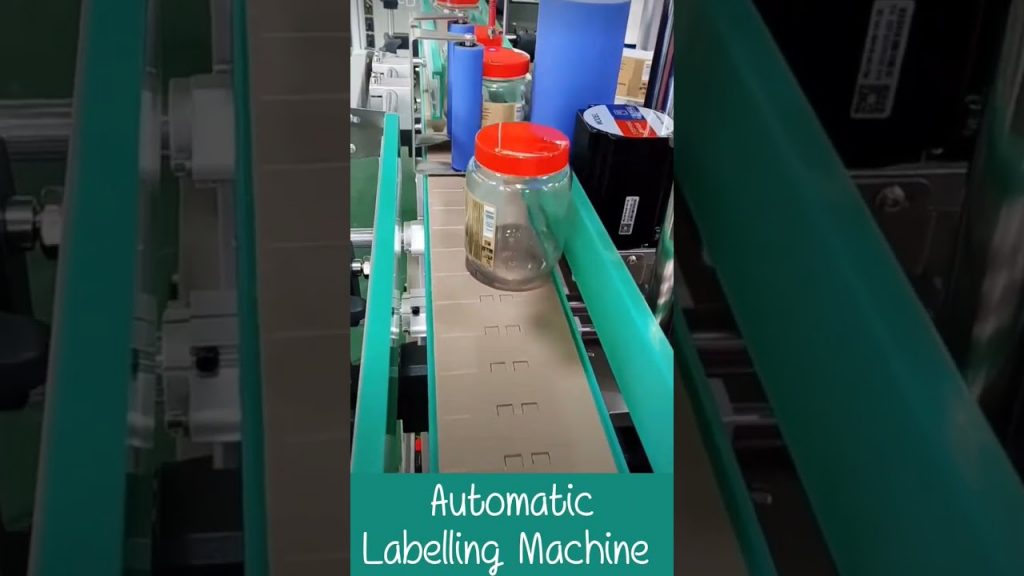

II. The Role of Automatic Labeling Machine:

Once the sports water bottles are molded, the next step is to label them. This is where the Automatic Labeling Machine comes into play. This machine automates the labeling process, ensuring accurate and efficient application of labels onto the bottles. The machine can handle various label types, such as adhesive labels or shrink sleeves, and can be customized to meet specific labeling requirements. With its high-speed operation and precise label placement, the Automatic Labeling Machine significantly improves productivity and reduces labor costs.

III. Benefits of Using Automatic Labeling Machine:

1. Efficiency: The Automatic Labeling Machine can label a high volume of sports water bottles in a short amount of time, ensuring a smooth production line and meeting customer demands.

2. Accuracy: With its precise label placement mechanism, the machine ensures that labels are applied correctly and uniformly on each bottle, enhancing product aesthetics and brand consistency.

3. Flexibility: The machine can handle different bottle shapes and sizes, making it suitable for a wide range of sports water bottle designs. This flexibility enables manufacturers to cater to diverse customer preferences.

4. Cost Savings: By automating the labeling process, manufacturers can reduce labor costs and minimize human errors. The Automatic Labeling Machine also eliminates the need for manual label application, freeing up resources for other production tasks.

IV. Automatic Labeling Machine in Action: A Case Study

To better understand the benefits of the Automatic Labeling Machine, let's look at a real-life scenario. ABC Sports Bottle Manufacturing Company recently incorporated an Automatic Labeling Machine into their production line. Before using the machine, they relied on manual labeling, which was time-consuming and prone to errors. However, with the new machine, they experienced a significant increase in labeling efficiency and accuracy. This improvement not only boosted their overall productivity but also enhanced their brand image, resulting in increased customer satisfaction and repeat business.

V. Conclusion:

The Injection Blow Molding Machine (IBM) with the Automatic Labeling Machine plays a vital role in the production of sports water bottles. The IBM ensures the bottles are molded with precision and consistency, while the Automatic Labeling Machine automates the labeling process, saving time and improving productivity. By incorporating these machines into their production lines, manufacturers can produce high-quality sports water bottles efficiently and meet the growing demand of consumers.

In summary, the combination of Injection Blow Molding Machine (IBM) and Automatic Labeling Machine offers a reliable and efficient solution for producing sports water bottles. With their advanced technology and automation capabilities, manufacturers can streamline their production processes and deliver top-notch products to customers. Labeling Machine

"Effortless Labeling for Pet Jars: The Ultimate Automatic Labelling Machine Solution!"