Check out the top-notch coil packing solution with the leading manufacturer for a professional solution right here:

---

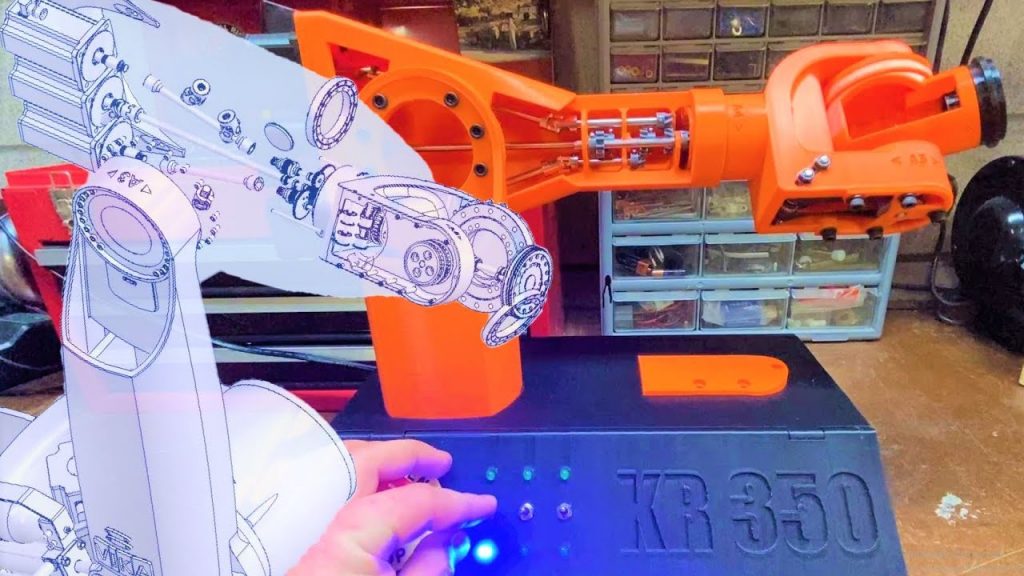

Title: Unveiling the Mastery of 3D Printing: The Functional KUKA KR350 Scale Model with an Industrial Robotic Arm

Introduction:

Countless hours spent in CAD, kilograms of filament utilized, and a multitude of trial and error experiments have finally led me to achieve a remarkable feat - a 1/4th scale model of the KUKA KR350 with an Industrial Robotic Arm. In this article, we delve into the world of 3D printing and explore the intricacies of this awe-inspiring creation. Join me as we uncover the immense potential and functionality of this scaled-down marvel.

Explanatory Style:

The advent of 3D printing has revolutionized the manufacturing industry, making it possible to bring intricate designs and ideas to life. The Functional KUKA KR350 Scale Model with an Industrial Robotic Arm is a prime example of this technological advancement. By harnessing the power of 3D printing, I have successfully replicated the capabilities of a full-sized industrial robotic arm in a compact form.

Narrative Structure:

Let me take you on a journey through the process of creating this impressive scale model. It all begins with countless hours spent meticulously designing the model using Computer-Aided Design (CAD) software. Every detail, from the arm's articulation to its range of motion, had to be carefully considered and accurately translated into the virtual world.

Once the design was finalized, it was time to bring it to life using 3D printing technology. Kilograms of filament were meticulously fed into the printer, layer by layer, as the intricate parts of the robotic arm gradually took shape. The precision and accuracy of the 3D printer ensured that each component fit seamlessly together, resulting in a fully functional model.

In-depth Analysis Style:

The Functional KUKA KR350 Scale Model with an Industrial Robotic Arm showcases the immense potential of 3D printing in the field of robotics. This scaled-down version accurately emulates the capabilities of its larger counterpart, making it an ideal tool for educational purposes or as a proof of concept.

The use of 3D printing technology allows for greater flexibility and customization in the design process. Modifications and improvements can be easily implemented, ensuring that the final product meets the specific requirements of the user. Additionally, the reduced size of the model makes it more accessible and affordable, opening doors for experimentation and innovation.

Argumentative Structure:

The Functional KUKA KR350 Scale Model with an Industrial Robotic Arm serves as a testament to the power of 3D printing in the manufacturing industry. Its intricate design and functionality showcase the potential for scaled-down robotic systems to revolutionize various sectors, including automation, healthcare, and even space exploration.

By harnessing the capabilities of 3D printing, we can create cost-effective and customizable robotic solutions that can be tailored to specific applications. This opens up a world of possibilities, allowing businesses and industries to streamline their operations and achieve greater efficiency.

Conclusion:

The Functional KUKA KR350 Scale Model with an Industrial Robotic Arm is a remarkable achievement, showcasing the immense potential of 3D printing in the field of robotics. This scaled-down marvel serves as a testament to the power of innovation and showcases the limitless possibilities that lie ahead.

So, if you're eager to witness the future of robotic technology, look no further. Check out the leading manufacturer's coil packing solution and explore the vast potential of this groundbreaking technology. Industrial Robot

"Exploring the Versatility of a 3D Printed Functional Scale Model Industrial Robotic Arm - KUKA KR350"