Title: Efficient Packaging Line Automation for Scarves | WIN-WIN PACK

Description:

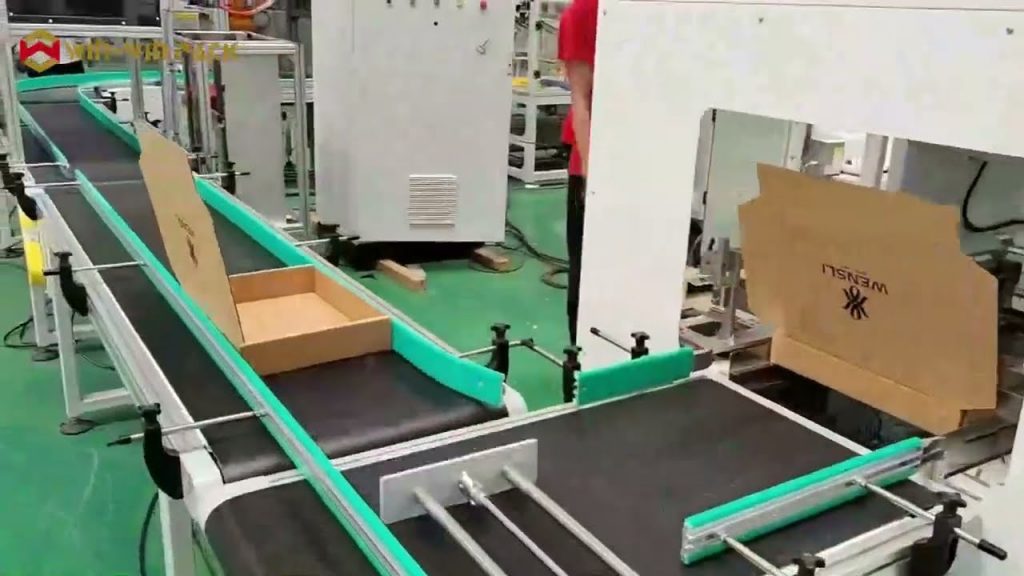

Welcome to WIN-WIN PACK, where we introduce you to our cutting-edge packaging line automation specially designed for scarves. From the initial tray forming to the final palletizing, our automatic packaging line ensures seamless and efficient packaging processes.

Tray Former:

Our state-of-the-art tray former utilizes corrugated trays, providing a sturdy and reliable packaging solution for scarves. With precision engineering, it forms trays with utmost accuracy, ensuring the safe transportation and storage of your valuable scarves.

Product Conveyance:

Efficiency is at the core of our packaging line automation. Our system includes a smooth and seamless product conveyance mechanism, optimizing the movement of scarves throughout the packaging process. This guarantees minimal downtime and maximizes productivity.

Packing and Sealing:

With advanced technology, our packaging line offers efficient and precise packing and sealing of scarves. It ensures that each scarf is perfectly packed and sealed, maintaining its quality and integrity during transportation and storage.

Quality Control:

We understand the importance of quality assurance. Our packaging line automation incorporates sophisticated quality control mechanisms, such as vision systems and sensors, to identify any defects or inconsistencies in scarf packaging. This ensures that only flawless scarves reach your customers.

Palletizing:

Effortlessly transforming the packaged scarves into pallets, our automated palletizing system optimizes stacking patterns, reducing space requirements and increasing stability during transportation. This eliminates the risk of damage and ensures efficient handling.

At WIN-WIN PACK, we prioritize customer satisfaction. By investing in our packaging line automation, you can significantly enhance your productivity, reduce labor costs, and improve overall efficiency. Don't miss out on the opportunity to revolutionize your scarf packaging processes.

Don't forget to like, subscribe, and share this video to help us reach more people in need of packaging line automation solutions. For additional information, please check the tags and keywords below, which will improve the visibility of this video in search results.

Tags: packaging line automation, scarf packaging, automated packaging, tray former, palletizing system, quality control, efficiency, productivity

Hashtags: #PackagingLineAutomation #Scarves #WINWINPACK #EfficientPackaging

Title: Streamlining Scarf Packaging with WIN-WIN PACK Automation

Introduction:

In the world of fashion, scarves are a popular accessory that requires efficient packaging solutions to meet consumer demands. To address this need, WIN-WIN PACK offers an advanced End-of-Line Packaging Automation system specifically designed for scarves. This innovative technology streamlines the packaging process, ensuring quick and accurate packaging while maximizing productivity and profitability for businesses. Let's explore the key features and benefits of the WIN-WIN PACK End-of-Line Packaging Automation for Scarves.

1. Enhanced Efficiency:

The WIN-WIN PACK system revolutionizes scarf packaging by automating various time-consuming tasks. From folding scarves to inserting them into individual packaging, this automation solution significantly reduces the overall packaging time. It eliminates the need for manual labor, allowing businesses to allocate their human resources to more value-added tasks.

2. Precise Packaging:

With its advanced sensors and cutting-edge technology, the WIN-WIN PACK Automation ensures precise and consistent packaging for every scarf. The system detects the size and shape of each scarf, adjusting the packaging process accordingly to provide a snug fit. This guarantees that scarves reach customers in impeccable condition, enhancing brand reputation and customer satisfaction.

3. Customization Options:

The WIN-WIN PACK system offers versatile packaging options that can be tailored to meet specific branding requirements. Businesses can customize packaging materials, insert promotional material, or include personalized messages, adding a touch of uniqueness to each scarf package. This level of customization helps to create a memorable unboxing experience for customers, fostering brand loyalty.

4. Cost-effective Solution:

Implementing the WIN-WIN PACK Automation minimizes packaging costs in the long run. By eliminating errors and reducing material waste, businesses can optimize their packaging process. Moreover, the system's energy-efficient design reduces electricity consumption, resulting in lower operational costs and improved sustainability.

5. Scalability and Flexibility:

WIN-WIN PACK understands the evolving needs of businesses. Their End-of-Line Packaging Automation system is designed to accommodate varying production volumes and adapt to changing packaging requirements. Whether a business is small-scale or large-scale, the WIN-WIN PACK system can be easily integrated into existing production lines or scaled up to meet growing demands.

Conclusion:

The WIN-WIN PACK End-of-Line Packaging Automation for Scarves revolutionizes the scarf packaging process by combining efficiency, precision, customization, cost-effectiveness, and scalability. By embracing this advanced automation technology, businesses can optimize their packaging operations, streamline production, and enhance customer satisfaction. Stay ahead in the competitive fashion industry by choosing WIN-WIN PACK as your trusted partner for scarf packaging automation. Automatic Packing Line

#WINWIN #PACK #EndofLine #Packaging #Automation #Scarves