Title: Streamline Your Packaging Process with the Pack Feeder 5 and Pack 202

Description:

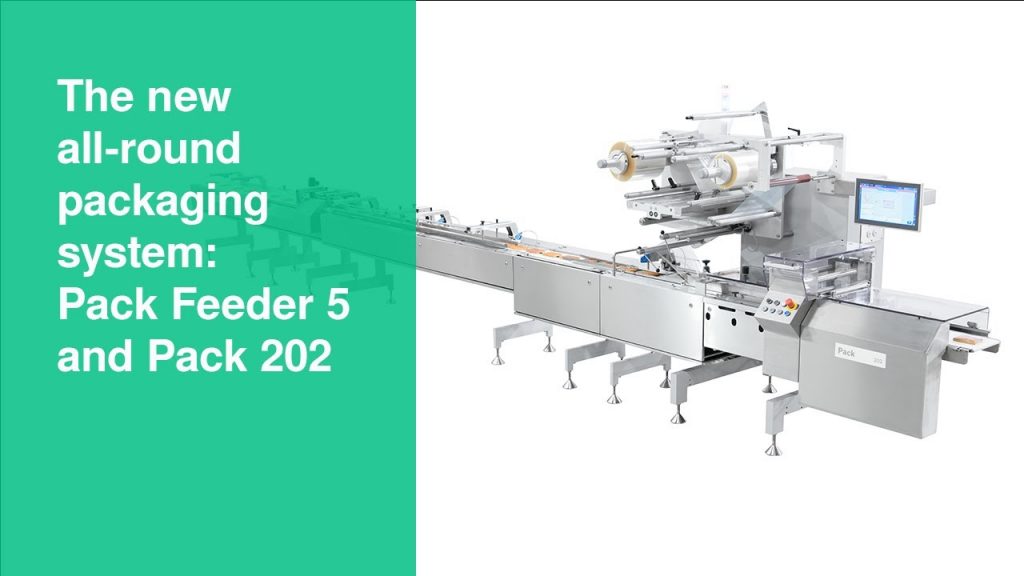

Welcome to our informative video showcasing the revolutionary Automated Packing Systems – the Pack Feeder 5 and Pack 202. These state-of-the-art automated horizontal flow wrapping machines are the new all-round packaging system that will transform your packaging operations.

The Pack 202 is a versatile solution suitable for a wide range of products, including bars, bakery items, cookies, crackers, and even non-food applications. Manufacturers across various industries can benefit from its exceptional capabilities and efficiency.

In this video, we provide a comprehensive overview of the Automated Packing Systems Pack Feeder 5 and Pack 202. Our expert team walks you through the key features, operation steps, and highlights of these cutting-edge machines.

Key Takeaways:

1. Enhanced Efficiency: Discover how the Pack Feeder 5 and Pack 202 streamline your packaging process, significantly reducing labor and time requirements.

2. Versatile Packaging: Learn how the Pack 202 caters to a multitude of products, both food and non-food, ensuring maximum flexibility for manufacturers.

3. Precise Wrapping: Explore the advanced horizontal flow wrapping technology that guarantees a superior packaging finish and product presentation.

4. Reliable Performance: Uncover the robust construction and durability of these automated systems, ensuring long-term efficiency and minimal downtime.

5. Cost Savings: Understand how the Pack Feeder 5 and Pack 202 contribute to cost reduction through increased productivity and minimized material wastage.

Whether you are a bakery, confectionery, or non-food manufacturer, the Pack Feeder 5 and Pack 202 offer a game-changing solution to optimize your packaging operations. Experience the future of automated packing and revolutionize your production line today.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with others in your industry. Stay updated with the latest advancements in automated packaging systems by joining our community.

Additional Tags and Keywords: automated packing systems, flow wrapping machines, Pack Feeder 5, Pack 202, packaging efficiency, versatile packaging, horizontal flow wrapping technology, cost-effective packaging, bakery packaging, confectionery packaging, non-food packaging

Hashtags: #automatedpacking #flowwrapping #packfeeder5 #pack202 #packagingsystems #efficiency #versatilepackaging #costsavings #bakerypackaging #confectionerypackaging #nonfoodpackaging

Title: Revolutionizing Packaging Efficiency: Introducing the Pack Feeder 5 and Pack 202 Tilter

Introduction:

In the fast-paced world of automated packaging, efficiency and versatility are paramount. Meet the all-new Pack Feeder 5 and Pack 202 Tilter, a groundbreaking packaging system that promises to revolutionize horizontal flow wrapping. With its cutting-edge technology and unparalleled performance, this dynamic duo guarantees improved productivity and reduced downtime, catering to the diverse needs of modern packaging operations.

Enhanced Automation:

The Pack Feeder 5 and Pack 202 Tilter boast state-of-the-art automation features that streamline the packaging process. By automating the feeding and tilting stages, these machines eliminate the need for manual intervention, boosting overall productivity. Through precise synchronization and advanced sensors, the system ensures seamless transitions, minimizing errors and maximizing throughput.

Flexible Packaging Solutions:

With its all-round capabilities, the Pack Feeder 5 and Pack 202 Tilter accommodate a wide range of packaging requirements. From delicate food items to sturdy industrial components, this system adapts to various product sizes, shapes, and weights with ease. Its adjustable settings allow for customizable packaging options, ensuring products are securely wrapped, regardless of their characteristics.

Optimized Workflow:

The Pack Feeder 5 and Pack 202 Tilter are designed to optimize workflow and minimize downtime. With quick changeover capabilities, the system efficiently switches between different products, reducing setup time and increasing operational efficiency. Its user-friendly interface simplifies operation, enabling operators to monitor and control the entire process effortlessly.

Advanced Safety Features:

Ensuring operator safety is a top priority, and the Pack Feeder 5 and Pack 202 Tilter excel in this aspect. Equipped with advanced safety mechanisms, including emergency stop functionality and protective barriers, operators can work confidently without compromising their well-being. The system adheres to strict safety standards, providing a secure working environment for all personnel involved.

Seamless Integration:

The Pack Feeder 5 and Pack 202 Tilter seamlessly integrate into existing packaging lines, making it an ideal choice for companies looking to upgrade their operations. These machines are designed to complement other equipment, ensuring smooth connectivity and enhancing overall system performance. The compatibility factor makes the transition to this all-round packaging system effortless and cost-effective.

Conclusion:

The Pack Feeder 5 and Pack 202 Tilter represent a significant leap forward in automated horizontal flow wrapping. Their innovative features, including enhanced automation, flexibility, optimized workflow, advanced safety measures, and seamless integration, make them the new all-round packaging system of choice. By investing in this dynamic duo, businesses can achieve higher productivity, reduced downtime, and ultimately, gain a competitive edge in the ever-evolving packaging industry. Automatic Packing Line

#Automated #horizontal #flow #wrapping #allround #packaging #system #Pack #Feeder #Pack