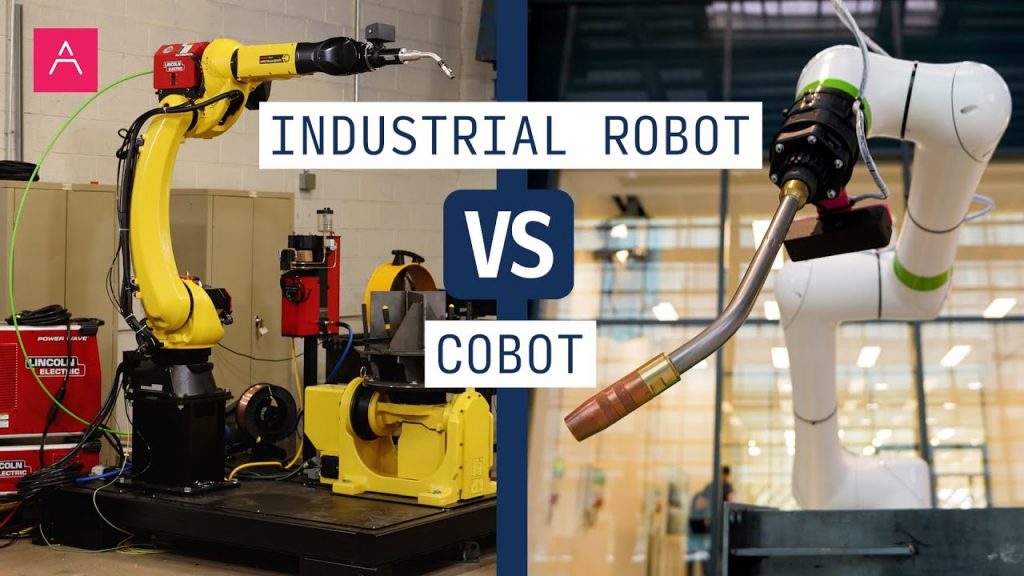

In this video, we explore the fascinating world of cobots and their comparison to industrial robots. If you're familiar with industrial robot programming, you may have heard about cobots and wondered how they differ. In this article, we'll delve into the details of cobot programming and highlight why it's not as easy as it may seem.

Cobots, or collaborative robots, are designed to work alongside humans in a shared workspace. Unlike traditional industrial robots, which are typically caged off and require specialized programming, cobots are designed to be user-friendly and easily programmable. They are built with advanced sensors and safety features that allow them to interact with humans safely and efficiently.

When it comes to programming cobots, there are a few key differences compared to industrial robots. One major distinction is the level of complexity. Industrial robots often require complex programming languages and extensive coding knowledge. On the other hand, cobots are designed to be intuitive and user-friendly, with programming interfaces that are accessible even to those without extensive technical backgrounds.

Cobot programming typically involves a combination of graphical user interfaces (GUIs), drag-and-drop programming, and pre-defined software modules. This makes it easier for operators to teach cobots specific tasks by simply guiding them through the desired movements. In contrast, industrial robot programming typically involves a more intricate process that requires specialized training and expertise.

While cobot programming may seem simpler on the surface, it still requires careful planning and consideration. Operators need to determine the appropriate tasks for the cobot, define the desired movements and sequences, and ensure the safety of both the cobot and the human workers. This requires a thorough understanding of the cobot's capabilities, as well as the specific requirements of the task at hand.

In addition to the programming aspect, it's important to consider the overall integration of cobots into the existing manufacturing processes. This includes ensuring compatibility with other machinery, optimizing workflow efficiency, and addressing any potential challenges that may arise during implementation. Proper planning and coordination are crucial to successfully incorporating cobots into the production line.

As cobots continue to gain popularity in various industries, it's important for manufacturers and operators to understand the nuances of cobot programming. While it may not be as complex as industrial robot programming, it still requires careful attention to detail and a solid understanding of the cobot's capabilities.

In conclusion, cobots offer a more accessible and user-friendly approach to automation in comparison to traditional industrial robots. Their programming interfaces and intuitive features make them easier to operate and integrate into existing manufacturing processes. However, it's important to recognize that cobot programming still requires careful planning and consideration to ensure optimal performance and safety.

Check the cobot programming solution with leading manufacturers for professional guidance and solutions in industrial robot programming. They can provide comprehensive support and expertise to help you effectively incorporate cobots into your production line. Industrial Robot

The Complexity of Cobot Programming: Unveiling the Challenges | Industrial Robot Programming Explored