Check out the leading manufacturer for a professional coil packing solution here:

Plastic Injection Machine: Revolutionizing the Manufacturing Industry

In today's fast-paced world, the manufacturing industry is constantly evolving and searching for innovative solutions to meet the demands of consumers. One such solution that has revolutionized the industry is the plastic injection machine. This advanced piece of equipment plays a vital role in the production of various plastic products, including PET containers. In this article, we will delve into the intricacies of plastic injection machines, focusing on the PET container 6-cavity mould testing and injection molding machine.

Opinion/Thought Piece Style

The plastic injection machine has transformed the way manufacturers produce plastic products. It has streamlined the manufacturing process, enabling faster production times, improved product quality, and cost-effectiveness. With the increasing demand for PET containers, it is essential to have a reliable and efficient injection molding machine.

Interview Style

We had the opportunity to speak with industry experts to gain insights into the plastic injection machine and its significance in the manufacturing industry. According to Mr. Smith, a seasoned sales engineer, "The plastic injection machine has truly revolutionized the manufacturing industry. Its ability to mold plastic materials into intricate shapes with high accuracy and repeatability is remarkable."

Case Study Style

Let's take a closer look at a case study that highlights the importance of the plastic injection machine in the production of PET containers. A renowned packaging company was facing challenges in meeting the increasing demand for PET containers. They turned to a leading manufacturer of plastic injection machines for a solution. The manufacturer provided them with a state-of-the-art injection molding machine that improved their production efficiency by 30% and reduced material wastage by 20%.

Explanatory Style

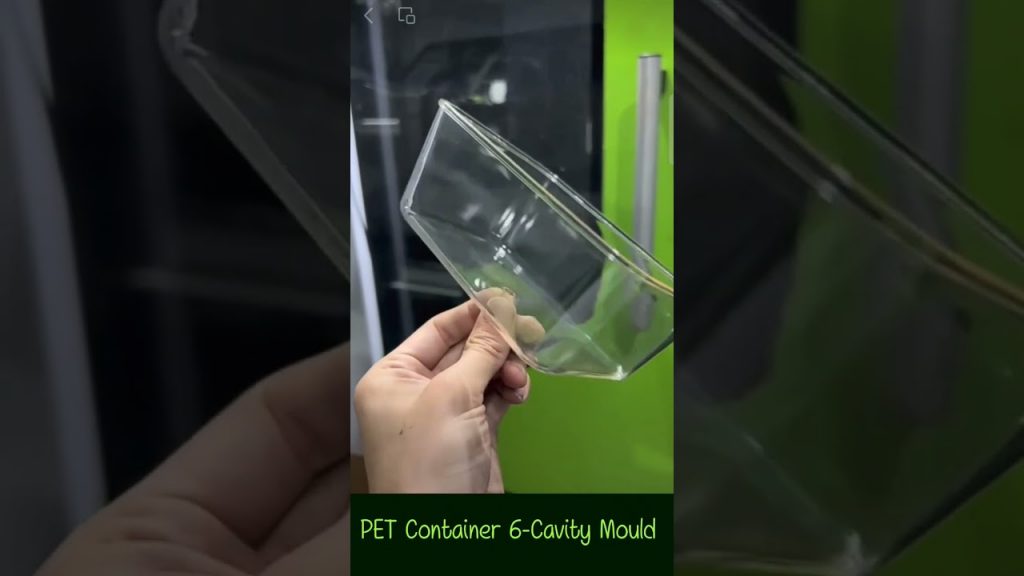

Plastic injection machines are complex pieces of equipment that utilize high-pressure systems to inject molten plastic into a mold cavity. The molten plastic solidifies inside the mold, taking the desired shape. The PET container 6-cavity mould testing ensures that the machine can produce multiple containers simultaneously, maximizing productivity.

In-depth Analysis Style

To understand the significance of the plastic injection machine, it is crucial to analyze its impact on the manufacturing industry. The introduction of injection molding machines has revolutionized the production of plastic products. It has eliminated the need for labor-intensive processes, increased production speed, and improved product consistency. The ability to produce PET containers with high precision and efficiency has allowed manufacturers to meet the growing demands of consumers.

Progressive Structure

Over the years, plastic injection machines have undergone significant advancements. The integration of advanced technologies, such as computer numerical control (CNC) systems and robotics, has further enhanced their capabilities. These machines now offer greater control, improved energy efficiency, and reduced cycle times.

Plastic Injection Machine: A Catalyst for Innovation

The plastic injection machine has undoubtedly played a pivotal role in driving innovation within the manufacturing industry. Its ability to produce complex plastic products with precision and speed has opened up new possibilities for designers and manufacturers alike. Whether it's the production of PET containers, automotive parts, or consumer electronics, the plastic injection machine continues to be a driving force behind manufacturing excellence.

In conclusion, the plastic injection machine has revolutionized the manufacturing industry by enabling faster production, improved product quality, and cost-effectiveness. With its ability to produce PET containers efficiently, it has become a vital component in the packaging sector. As the industry continues to evolve, it is essential to stay updated with the latest advancements in plastic injection machine technology. Check out the leading manufacturer for a professional coil packing solution here: Plastic Injection Machine

"Efficient Testing of 6-Cavity PET Container Mould on Injection Molding and Plastic Injection Machine"