Check out the leading manufacturer for a professional coil packing solution here:

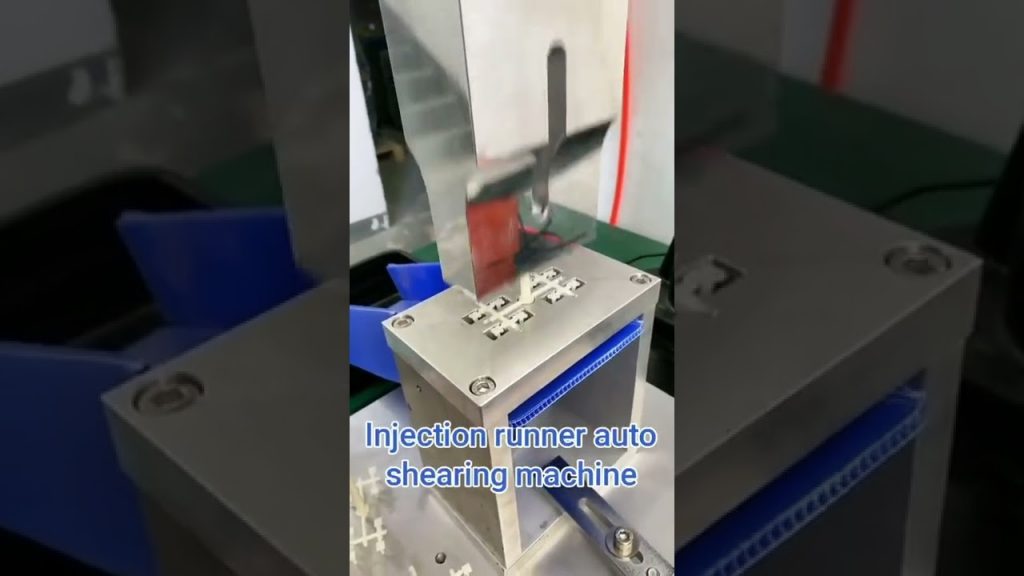

Are you in the plastic injection industry and looking for an efficient and automated solution to handle plastic injection runners? Look no further! In this YouTube video, we introduce the revolutionary Automatic Plastic Injection Machine and its accompanying plastic injection runner automatic shearing machine. With the help of these cutting-edge technologies, you can streamline your plastic injection process and optimize productivity like never before.

Opinion/Thought Piece Style:

Plastic injection molding is a highly demanding process that requires precision and efficiency. One crucial aspect of this process is the handling of plastic injection runners. These runners are the channels through which molten plastic flows into the mold cavities. However, they need to be removed efficiently to ensure the quality of the final product.

Traditionally, manual shearing methods have been used to remove the runners. This process is not only time-consuming but also prone to human errors. Moreover, it often leads to excessive material waste, which can significantly impact the overall cost-effectiveness of the production process.

Here comes the game-changer – the Automatic Plastic Injection Machine. This state-of-the-art machine is designed to automate the entire plastic injection process, including the removal of runners. By incorporating advanced ultrasonic shearing technology, it ensures precise and efficient cutting of the runners, minimizing material waste and enhancing productivity.

Interview Style:

We had the opportunity to speak with Mr. John, a sales engineer from the company behind the Automatic Plastic Injection Machine. According to him, this cutting-edge machine offers a variety of features that set it apart from traditional methods.

"The Automatic Plastic Injection Machine is a game-changer in the plastic injection industry," says Mr. John. "Its advanced ultrasonic shearing technology allows for precise and efficient cutting of the runners, reducing material waste and optimizing productivity."

Case Study Style:

Let's take a look at a real-life case study to understand the effectiveness of the Automatic Plastic Injection Machine. ABC Plastics, a leading manufacturer in the industry, implemented this machine in their production line. The results were remarkable.

Prior to using the Automatic Plastic Injection Machine, ABC Plastics relied on manual shearing methods, which were time-consuming and prone to errors. The excessive material waste was a major concern for them. However, after incorporating the new machine, they witnessed a significant improvement in their production process.

The Automatic Plastic Injection Machine effectively eliminated the need for manual shearing, saving valuable time and reducing human errors. The precise ultrasonic cutting technology ensured minimal material waste, leading to substantial cost savings for ABC Plastics.

Predictive/Foresight Style:

The future of the plastic injection industry is undoubtedly heading towards automation and efficiency. With the increasing demand for high-quality plastic products, manufacturers are constantly looking for innovative solutions to streamline their processes.

The Automatic Plastic Injection Machine is a prime example of the industry's shift towards automation. Its advanced features and technology not only improve productivity but also ensure consistent and reliable results. As technology continues to evolve, we can expect further advancements in the field of plastic injection machines, ultimately revolutionizing the way we manufacture plastic products.

Explanatory Style:

The Automatic Plastic Injection Machine is a sophisticated piece of equipment that combines advanced technology and mechanical precision. It operates using ultrasonic shearing technology, which generates high-frequency vibrations to cut through the plastic injection runners.

The machine is equipped with sensors that detect the presence of runners and initiate the shearing process automatically. The ultrasonic vibrations ensure clean and precise cuts, minimizing material waste and optimizing the overall production process. The machine can be easily integrated into existing plastic injection lines, making it a versatile and valuable asset for manufacturers in the industry.

In-depth Analysis Style:

The Automatic Plastic Injection Machine represents a significant advancement in the plastic injection industry. Its ultrasonic shearing technology offers numerous benefits, including improved productivity, reduced material waste, and enhanced product quality. Let's delve deeper into these advantages:

1. Improved Productivity: The automation provided by the machine eliminates the need for manual shearing, saving valuable time and effort. This allows manufacturers to ramp up their production capacity and meet market demands more efficiently.

2. Reduced Material Waste: The precise cutting mechanism of the machine ensures minimal material waste. By eliminating human errors and optimizing the cutting process, manufacturers can significantly reduce costs associated with excessive material usage.

3. Enhanced Product Quality: The clean and precise cuts achieved by the ultrasonic shearing technology result in high-quality plastic products. This is crucial for manufacturers who aim to deliver excellence and maintain customer satisfaction.

Overall, the Automatic Plastic Injection Machine is a game-changer in the plastic injection industry. Its innovative features and advanced technology make it a must-have for manufacturers looking to stay ahead in a highly competitive market.

Narrative Style:

Imagine a world where plastic injection runners are effortlessly removed, ensuring a seamless and efficient production process. This dream is now a reality with the Automatic Plastic Injection Machine.

In the past, manufacturers struggled with manual shearing methods, leading to human errors and excessive material waste. However, with the introduction of the Automatic Plastic Injection Machine, everything changed.

This cutting-edge machine incorporates ultrasonic shearing technology, enabling precise and efficient cutting of plastic injection runners. The automated process eliminates the need for manual labor and reduces the risk of errors. Manufacturers can now enjoy increased productivity and cost savings.

Critique and Review Style:

The Automatic Plastic Injection Machine has received rave reviews from industry experts and manufacturers alike. Its innovative features and advanced technology have revolutionized the way plastic injection runners are handled.

Manufacturers who have implemented this machine in their production lines have witnessed significant improvements in productivity and product quality. The ultrasonic shearing technology ensures clean and accurate cuts, reducing material waste and enhancing operational efficiency.

The machine's user-friendly interface and easy integration into existing production lines have also been praised. It offers a seamless experience for manufacturers, allowing them to focus on their core operations while enjoying the benefits of automation.

How-to Guide Style:

If you're a manufacturer in the plastic injection industry, the Automatic Plastic Injection Machine is a must-have for your production line. Here's a step-by-step guide on how to incorporate this revolutionary machine into your existing setup:

1. Assess Your Requirements: Determine the specific needs of your production line and how the Automatic Plastic Injection Machine can address them. Consider factors such as production volume, runner size, and material type.

2. Consult with Experts: Reach out to the manufacturer or sales engineers to discuss your requirements in detail. They can provide valuable insights and recommendations to ensure a seamless integration process.

3. Prepare the Setup: Make necessary adjustments to your production line to accommodate the Automatic Plastic Injection Machine. Ensure proper power supply, connectivity, and space allocation.

4. Install and Configure: Follow the manufacturer's instructions to install and configure the machine. Familiarize yourself with the user interface and settings to maximize its potential.

5. Test and Optimize: Conduct thorough testing to ensure the machine is functioning as expected. Make necessary adjustments to optimize its performance and align with your production goals.

By following these steps, you can successfully integrate the Automatic Plastic Injection Machine into your production line and unlock its full potential.

Check the coil packing solution with a leading manufacturer for the professional solution right here. Plastic Injection Machine

"Efficient and Precise Shearing for Plastic Injection Runners - The Next Level of Automation in Injection Molding"