Check out our video on Paulson Training Programs, Inc. Lesson #1 - Molding Machine Parts and Operation-The Technology of Injection Molding – Level ... with Used Plastic Injection Machine. In this article, we will provide you with an SEO-friendly summary of the video, along with a reference to the Used Plastic Injection Machine and Lesson 1-HD - Molding Machine Parts and Operation - Technology of Injection Molding. We will present the information in an explanatory style, focusing on the keywords "Used Plastic Injection Machine."

Introduction:

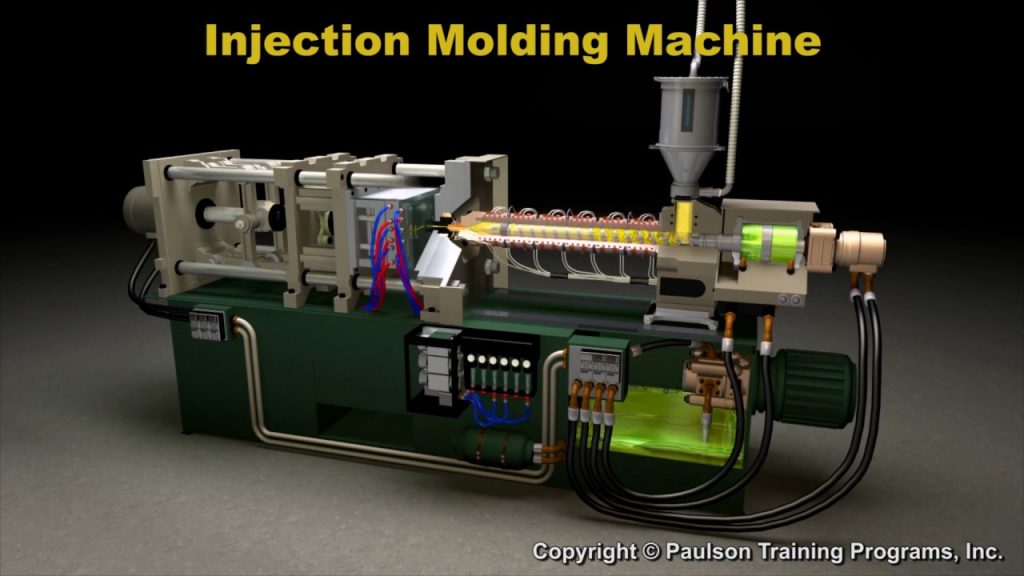

In the world of manufacturing, injection molding is a widely used technique for creating plastic parts. It involves melting plastic pellets and injecting the molten material into a mold to form the desired shape. To understand the technology behind injection molding, it is essential to have a good grasp of the various parts and operation of molding machines. This is where Paulson Training Programs, Inc. comes in. They offer comprehensive training courses that cover the fundamentals of injection molding, including Lesson #1 - Molding Machine Parts and Operation-The Technology of Injection Molding.

Lesson #1 - Molding Machine Parts and Operation:

This lesson is an excellent starting point for anyone interested in learning about injection molding. It provides a detailed overview of the different components of a molding machine and explains their functions. From the injection unit to the clamping unit, each part plays a crucial role in the injection molding process. By understanding how these components interact, operators can optimize machine performance and troubleshoot any issues that may arise.

The Technology of Injection Molding:

Injection molding has evolved significantly over the years, thanks to advancements in technology. This video sheds light on the latest innovations in the industry, such as the integration of sensors and automation systems. These technological advancements have improved the accuracy, efficiency, and reliability of molding machines, resulting in higher-quality plastic parts. By staying up-to-date with the latest technology, manufacturers can enhance their production processes and stay competitive in the market.

Used Plastic Injection Machine:

If you're considering investing in a plastic injection machine, you may want to explore the option of purchasing a used machine. Used plastic injection machines offer a cost-effective solution for manufacturers looking to expand their production capabilities. However, it is crucial to ensure that the used machine is in good working condition and meets your specific requirements. By partnering with a trusted supplier, you can find a high-quality used plastic injection machine that suits your needs.

Conclusion:

Paulson Training Programs, Inc. Lesson #1 - Molding Machine Parts and Operation-The Technology of Injection Molding is a valuable resource for individuals and businesses involved in the injection molding industry. By understanding the different parts and operation of molding machines, operators can optimize their production processes and troubleshoot any issues that may arise. Additionally, staying updated with the latest technology and considering the option of a used plastic injection machine can help manufacturers enhance their capabilities while maintaining cost-efficiency.

Check out the video to learn more about Paulson Training Programs, Inc. Lesson #1 - Molding Machine Parts and Operation-The Technology of Injection Molding – Level ... with Used Plastic Injection Machine! Plastic Injection Machine

"Molding Machine Parts and Operation: Understanding the Technology of Injection Molding and Used Plastic Injection Machines"