Today, the productivity rate of pick & place units in electronics and small-parts assembly is measured in cycle times ranging below what was once thought possible. With the advancement of Industrial Automation Robots, these units have become more efficient than ever before. In this article, we will delve into the world of Industrial Automation Robots and explore how they have revolutionized the field of factory automation and robotics.

Industrial Automation Robots have become indispensable in the manufacturing industry, particularly in electronics and small-parts assembly. These robots are designed to perform repetitive tasks with precision and speed, allowing for increased productivity and reduced labor costs. With their ability to handle delicate components and operate at high speeds, they have transformed the way products are assembled.

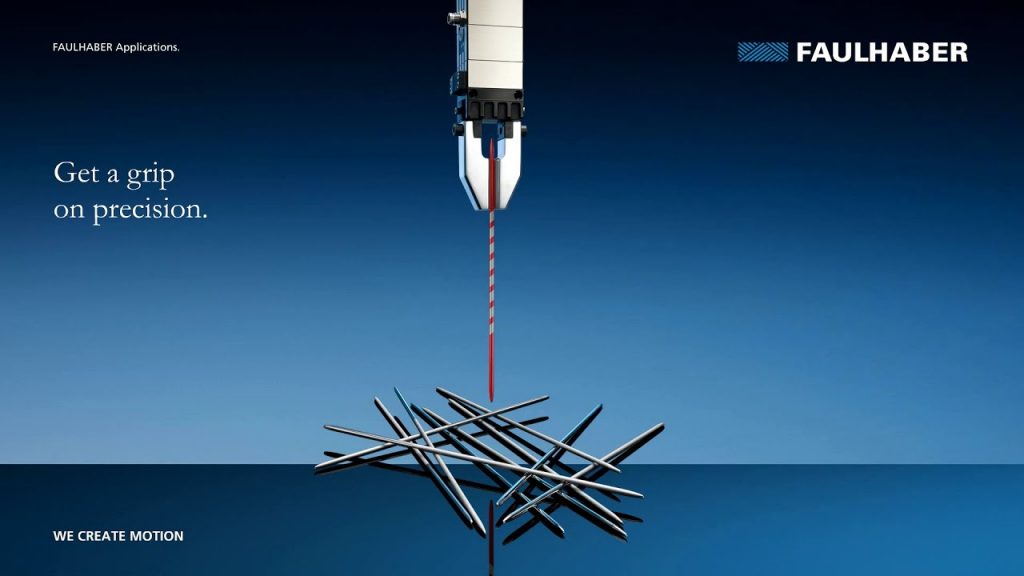

One of the key components of Industrial Automation Robots is the gripper. Grippers are designed to securely hold and manipulate objects during the assembly process. They come in various forms, such as vacuum grippers, magnetic grippers, and mechanical grippers. Each type of gripper is suited for different applications, depending on the size and fragility of the components being handled.

The use of Industrial Automation Robots and grippers has significantly improved the productivity rate of pick & place units. These robots can perform tasks at a much faster pace than human workers, greatly reducing cycle times. This means that products can be manufactured and assembled at a quicker rate, allowing for increased output and faster delivery times.

In addition to speed, Industrial Automation Robots also offer enhanced accuracy and precision. Their advanced sensors and programming capabilities ensure that components are placed in the correct position with minimal errors. This not only improves the quality of the final product but also reduces the need for rework or manual adjustments.

Furthermore, Industrial Automation Robots have proven to be cost-effective in the long run. While the initial investment may be higher compared to manual labor, these robots can work around the clock without the need for breaks or rest. This significantly reduces labor costs and increases overall production efficiency.

The integration of Industrial Automation Robots into the manufacturing process has also led to improved worker safety. By automating repetitive and potentially hazardous tasks, the risk of injuries and accidents is greatly reduced. This allows human workers to focus on more complex and value-added tasks, improving job satisfaction and overall well-being.

Looking ahead, the future of Industrial Automation Robots in electronics and small-parts assembly looks promising. With advancements in artificial intelligence and machine learning, these robots will become even smarter and more adaptable. They will be able to learn from past experiences and optimize their performance, further increasing productivity and efficiency.

In conclusion, Industrial Automation Robots have revolutionized the field of factory automation and robotics. Their ability to perform repetitive tasks with speed, precision, and accuracy has transformed the productivity rate of pick & place units in electronics and small-parts assembly. With their cost-effectiveness and enhanced worker safety, these robots have become an invaluable asset in the manufacturing industry. The future holds even more exciting possibilities as technology continues to advance.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

"Enhancing Industrial Efficiency: Exploring the Versatility of Gripper and Automation Robots for Factory Automation & Robotics"