If you're interested in learning about automated wheel hub production lines and the use of QJAR robots in the process, you've come to the right place. In this article, we will explore the fascinating world of industrial robot manufacturers and their role in the wheel hub handling industry. We'll also delve into the concept of industry 4.0 and how it has transformed the manufacturing landscape.

Title: Enhancing Efficiency in Wheel Hub Production with QJAR Robots: A Closer Look at Industrial Robot Manufacturers

Introduction:

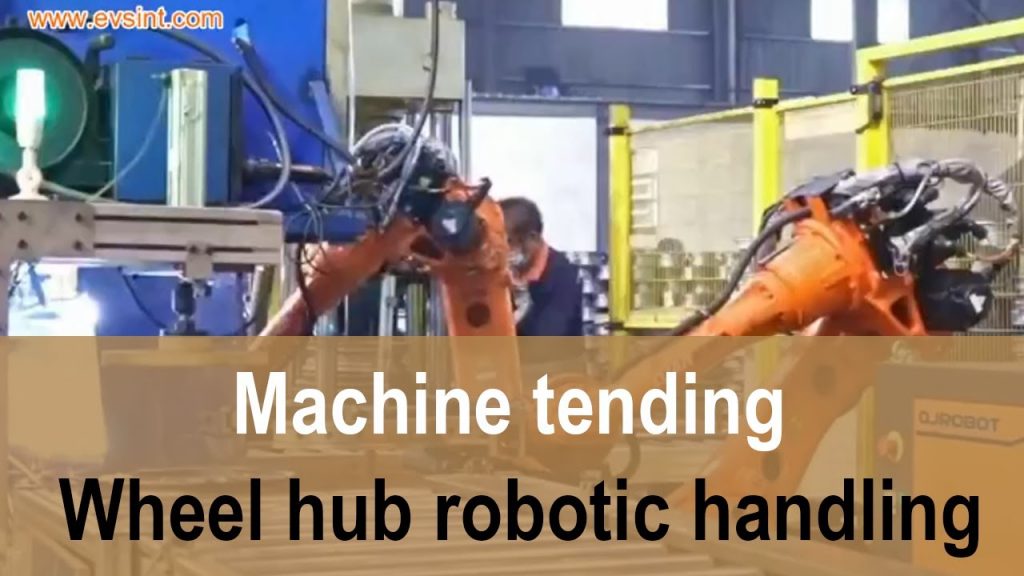

In the ever-evolving world of manufacturing, automation has become a key driver of efficiency and productivity. One area where automation has made a significant impact is in the production of wheel hubs. This article will take you behind the scenes of an automated wheel hub production line, where QJAR robots play a vital role in streamlining processes and maximizing output.

Section 1: The Evolution of Industrial Robot Manufacturers:

To understand the significance of QJAR robots in the wheel hub handling industry, it is important to explore the evolution of industrial robot manufacturers. Over the years, these manufacturers have continually pushed the boundaries of automation technology, resulting in more advanced and capable robots. From early mechanical arms to the sophisticated robots of today, industrial robot manufacturers have revolutionized the manufacturing landscape.

Section 2: The Automated Wheel Hub Production Line:

In this section, we will dive into the specifics of an automated wheel hub production line. With a payload capacity of 50kg and an impressive reaching distance of 2012mm, QJAR robots provide the perfect solution for handling wheel hubs efficiently and effectively. These robots are equipped with state-of-the-art technology that enables them to perform tasks with precision and speed, ensuring an uninterrupted production process.

Section 3: Industry 4.0 and Its Impact:

Industry 4.0, also known as the Fourth Industrial Revolution, has brought about a paradigm shift in manufacturing. It involves the integration of digital technologies, such as artificial intelligence and the Internet of Things, with traditional manufacturing processes. This section will explore how QJAR robots and the automated wheel hub production line align with the principles of industry 4.0, resulting in a more connected and intelligent manufacturing environment.

Section 4: Case Study: Maximizing Efficiency with QJAR Robots:

To provide a real-world perspective, we will discuss a case study where a manufacturing company implemented QJAR robots in their wheel hub production line. By doing so, they were able to achieve significant improvements in efficiency, reduce downtime, and enhance overall product quality. This case study serves as a testament to the effectiveness of QJAR robots in the wheel hub handling industry.

Section 5: The Future of Industrial Robot Manufacturers:

As technology continues to advance at a rapid pace, the future of industrial robot manufacturers looks promising. This section will explore the potential advancements and innovations that we can expect to see in the coming years. From enhanced sensor technology to collaborative robots, the possibilities are endless.

Conclusion:

In conclusion, the integration of QJAR robots in automated wheel hub production lines has revolutionized the manufacturing process. Industrial robot manufacturers have played a pivotal role in driving this transformation, and their continuous innovation has paved the way for increased efficiency and productivity. As we move further into the era of industry 4.0, the importance of automation and intelligent manufacturing will only continue to grow.

Check the coil packing solution with leading manufacturers for professional solutions in the industry. Industrial Robot

"Revolutionizing Robotic Machine Tending and Wheel Hub Handling in the Industry 4.0 Era: Discover Top Industrial Robot Manufacturers"