Labeling Machine is an essential tool in the packaging industry that helps businesses streamline their labeling process and improve efficiency. In this YouTube video, we will guide you on how to use the Manual Round Labeling Machine MT30 effectively. Whether you are a small business owner or a packaging professional, this step-by-step guide will provide you with valuable insights on maximizing the potential of your labeling machine.

Before we dive into the details, let's take a moment to understand the importance of labeling in the packaging industry. Labels not only provide crucial information about a product but also serve as a branding tool. A well-designed and correctly applied label can attract customers, enhance brand recognition, and ensure regulatory compliance.

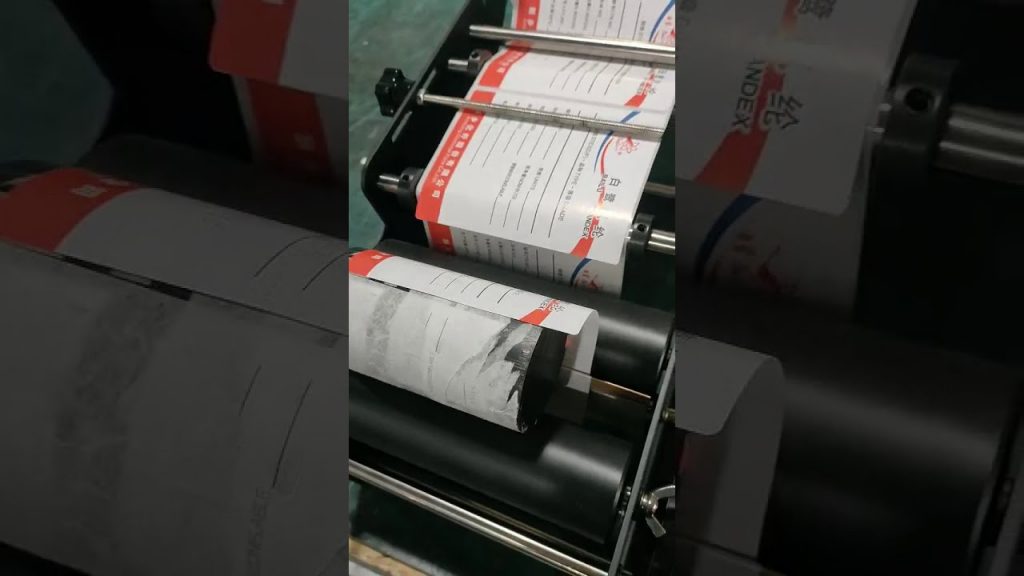

Now, let's get started with the basics of the Manual Round Labeling Machine MT30. This versatile machine is designed specifically for round containers such as bottles, jars, and tubes. Its manual operation allows for precise and efficient labeling, making it an ideal choice for small to medium-scale production.

Step 1: Set up the Machine

Begin by placing the Manual Round Labeling Machine MT30 on a stable surface. Make sure it is securely positioned to prevent any accidents during operation. Ensure that the labeling machine is properly aligned and leveled.

Step 2: Adjust the Labeling Parameters

The Manual Round Labeling Machine MT30 offers flexibility in adjusting various parameters to suit different labeling needs. These parameters include label size, label position, and label speed. Refer to the machine's user manual to understand the adjustments required for your specific labeling requirements.

Step 3: Prepare the Labels

Load the labels onto the labeling machine's label holder. Make sure the labels are neatly stacked and positioned correctly to avoid any misalignment during the labeling process. Adjust the tension on the label holder to ensure smooth label feed.

Step 4: Load the Containers

Place the round containers to be labeled in the machine's container holder. Ensure that the containers are positioned securely to prevent any movement during the labeling process. The Manual Round Labeling Machine MT30 can handle various sizes of round containers, making it a versatile option for different packaging needs.

Step 5: Start the Labeling Process

Once everything is set up, it's time to start the labeling process. Turn on the machine and activate the labeling mechanism. The Manual Round Labeling Machine MT30 will automatically apply the labels onto the round containers as they pass through the labeling area. Ensure that the labels are applied accurately and without any wrinkles or bubbles.

Step 6: Inspect and Verify

After the labeling process is complete, carefully inspect the labeled containers to ensure that the labels are properly applied. Look for any defects or inconsistencies that may affect the overall quality of the labeled products. Make any necessary adjustments to the machine or labeling parameters if required.

By following these steps, you can effectively utilize the Manual Round Labeling Machine MT30 and enhance your packaging process. This machine offers a cost-effective solution for small to medium-scale labeling needs, providing businesses with increased efficiency and accuracy.

In conclusion, the Manual Round Labeling Machine MT30 is a valuable asset for businesses in the packaging industry. Its user-friendly design and versatility make it an ideal choice for labeling round containers. By understanding the proper usage and following the step-by-step guide provided in this video, you can harness the full potential of this labeling machine and optimize your packaging process.

Check the coil packing solution with leading manufacturers for professional solutions just here. Labeling Machine

"Efficient Labeling Techniques: A Step-by-Step Guide to Using Manual Round Labeling Machines and Labeling Machines"