Title: Mastering the Art of Natural Fiber Biodegradable Food Packaging with Innovative Equipment

Description:

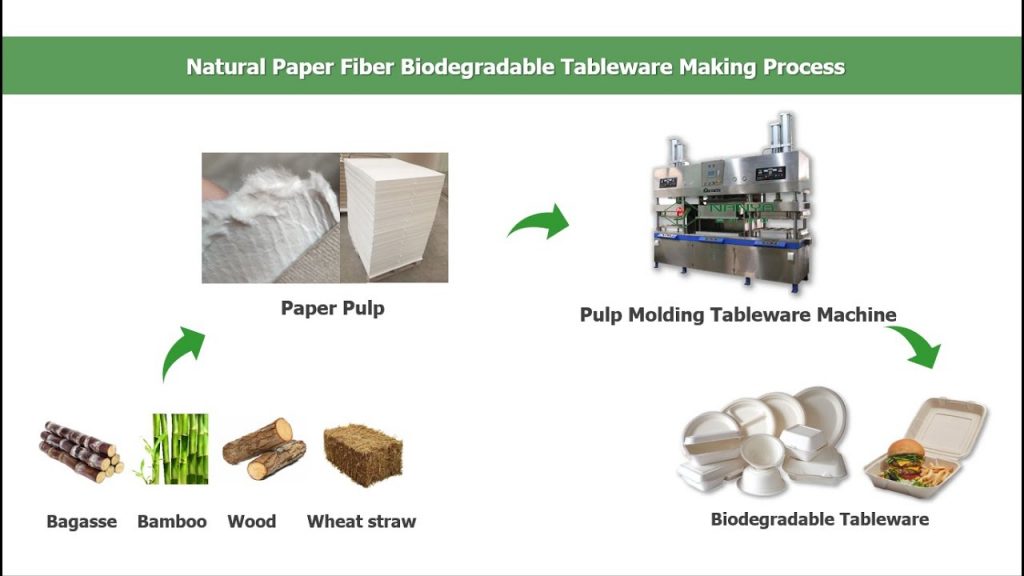

Welcome to our informative video on Food Packaging Equipment and the fascinating production process of natural paper molded fiber biodegradable food packaging. In this video, we will explore the step-by-step guide on how to produce eco-friendly food packaging using paper fiber as the raw material.

Introduction:

In today's world, where sustainability is a pressing concern, finding effective solutions for eco-friendly packaging is crucial. Our video delves into the realm of natural fiber biodegradable food packaging, highlighting its benefits and the innovative equipment used in its production.

Video Content:

1. Understanding Natural Fiber Biodegradable Food Packaging:

- Discover the concept behind natural fiber packaging and its significance in reducing environmental impact.

- Learn how this packaging solution embraces biodegradability by utilizing paper fiber as the main raw material.

2. Exploring Food Packaging Equipment:

- Uncover the cutting-edge machinery specifically designed for the production of natural fiber biodegradable food packaging.

- Witness the automated processes and advanced technology that streamline the manufacturing process.

3. Production Process of Natural Fiber Biodegradable Food Packaging:

- Dive into the step-by-step guide on how to produce this sustainable packaging, from raw material preparation to final product formation.

- Gain insights into the intricacies of the machinery and techniques employed to create sturdy and eco-friendly packaging solutions.

4. Key Highlights and Interesting Facts:

- Discover fascinating facts and insights about the benefits of natural paper molded fiber biodegradable food packaging.

- Learn about its exceptional strength, versatility, and compatibility with various food products.

Call to Action:

If you found this video informative and inspiring, please consider giving it a thumbs up, subscribing to our channel for more enlightening content, and sharing it with others who are passionate about sustainable packaging solutions.

Additional Tags and Keywords: food packaging, eco-friendly packaging, biodegradable packaging, sustainable packaging, natural fiber packaging, paper molded fiber, production process, packaging equipment, eco-friendly solutions, environmentally friendly packaging.

Hashtags: #FoodPackaging #EcoFriendlyPackaging #BiodegradableSolutions #SustainablePackaging #NaturalFiberPackaging #PackagingEquipment

Title: Optimizing the Natural Paper Molded Fiber Biodegradable Food Packaging Machine Production Process

Introduction:

The production of natural paper molded fiber biodegradable food packaging is an environmentally friendly alternative to traditional packaging materials. To ensure efficient and cost-effective production, the use of a tilter is proposed to enhance the overall production process. This article aims to outline the benefits of incorporating a tilter into the production line and its impact on improving productivity and quality.

1. Enhanced Material Handling:

The tilter can be used to efficiently handle and transport raw materials, such as natural paper fibers, throughout the production process. By automating the material handling process, the tilter reduces manual labor, minimizes the risk of injuries, and increases productivity.

2. Improved Mold Filling:

With the help of a tilter, the mold filling process can be optimized. The tilter can precisely control the angle and speed at which the natural paper fibers are deposited into the molds, ensuring consistent and uniform distribution. This leads to enhanced product quality and reduces the need for rework.

3. Reduced Drying Time:

By tilting the molds, excess moisture can be easily drained, significantly reducing the drying time required for the molded fiber products. This results in faster production cycles, increased output, and improved overall efficiency.

4. Enhanced Demolding Process:

The tilter plays a crucial role in the demolding process by carefully tilting the molds to release the formed natural paper molded fiber packaging. This automated demolding process reduces the risk of product damage and accelerates the overall production speed.

5. Flexibility in Mold Design:

The incorporation of a tilter allows for greater flexibility in mold design. The adjustable angles of the tilter enable the production of unique shapes and sizes of biodegradable food packaging, catering to various customer requirements. This versatility in design enhances product differentiation and market competitiveness.

6. Quality Control:

The tilter facilitates efficient quality control by ensuring consistent mold filling and demolding processes. This reduces the chances of defective products, improves the overall quality of the packaging, and enhances customer satisfaction.

Conclusion:

Incorporating a tilter into the natural paper molded fiber biodegradable food packaging machine production process offers numerous advantages, including enhanced material handling, improved mold filling, reduced drying time, streamlined demolding, flexibility in mold design, and efficient quality control. By optimizing these processes, manufacturers can achieve higher productivity, improved product quality, and contribute to a sustainable and eco-friendly packaging industry.Food Packing Machine

#Natural #paper #molded #fiber #biodegradable #food #packaging #machine #production #process