Title: Automated Packing Systems 1390HCB - Automatic Mattress Packaging with Compression, Single Fold & Roll Pack | Perfect Solution for E-commerce Shipping

Description:

Introduction:

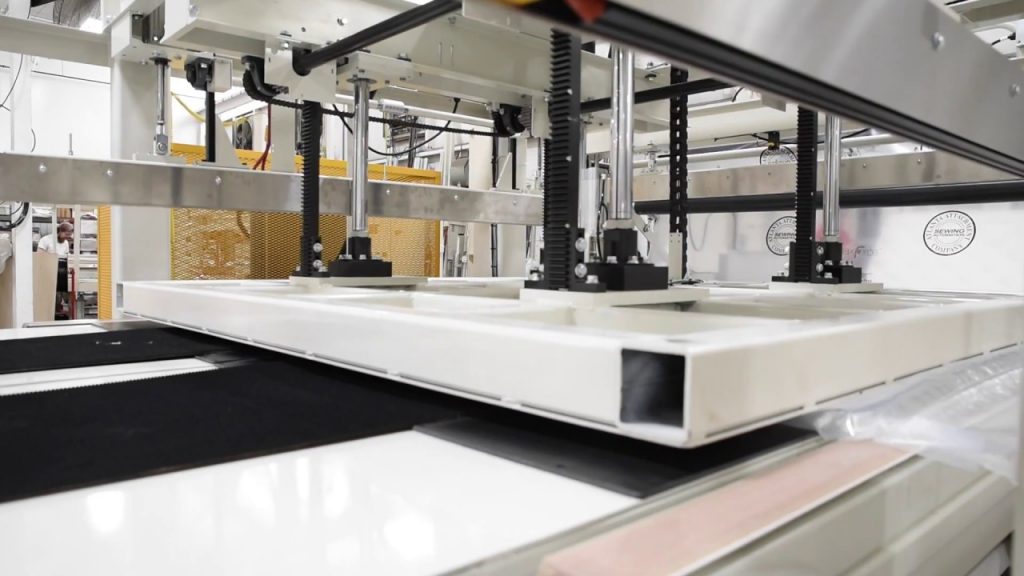

Welcome to our video showcasing the revolutionary Automated Packing Systems 1390HCB, an advanced and efficient solution for mattress packaging. In this video, we will explore the features and benefits of this innovative system, highlighting its capabilities in compressing, single folding, and roll packing mattresses for seamless e-commerce shipping.

Video Content:

Our Automated Packing System 1390HCB offers a comprehensive solution for efficiently packaging mattresses, ensuring convenient shipping and storage. With its state-of-the-art technology, this system automates the packaging process, saving time and effort for mattress manufacturers and e-commerce businesses alike.

Key Features:

1. Compression: The 1390HCB system utilizes compression technology to reduce the size of mattresses, optimizing storage space and minimizing shipping costs.

2. Single Fold & Roll Pack: This system enables the mattress to be folded and rolled into a compact form, ensuring easy handling and transportation. It streamlines the packaging process, making it ideal for e-commerce businesses.

3. Conventional Bagging (via Pass-through Mode): Our innovative system allows for automated wrapping of mattresses using conventional bagging techniques. This pass-through mode ensures seamless packaging, adding an extra layer of protection during shipping.

Benefits:

- Enhanced Efficiency: The 1390HCB system significantly reduces the time and effort required for mattress packaging, increasing productivity and streamlining operations.

- Cost Savings: By compressing mattresses and utilizing efficient packaging methods, businesses can save on storage space, shipping costs, and overall logistics expenses.

- Perfect for E-commerce: With the rise of online mattress sales, the 1390HCB system caters to the specific needs of e-commerce businesses, ensuring hassle-free packaging and seamless shipping to customers.

Call to Action:

If you found this video informative and useful, please consider liking, subscribing, and sharing it with others who may benefit from our Automated Packing System 1390HCB. Stay updated with the latest innovations in mattress packaging by subscribing to our channel.

Additional Tags and Keywords:

Automated Packing Systems, mattress packaging, compression technology, single fold and roll pack, e-commerce shipping, pass-through mode, innovative packaging solution, efficient mattress packaging, cost-effective, time-saving, enhanced productivity, online mattress sales.

Hashtags:

#AutomatedPackingSystems #MattressPackaging #EcommerceShipping #EfficientPackaging #CostSavings #InnovativeTechnology

Title: Advanced Tilter for 1390HCB - Automatic Mattress Packaging with Compression, Single Fold & Roll Pack

Introduction:

The 1390HCB Automatic Mattress Packaging machine revolutionizes the mattress packaging industry with its innovative features, including compression, single fold, and roll pack capabilities. To further enhance its functionality and efficiency, an advanced tilter is introduced. This tilter is designed to seamlessly integrate with the 1390HCB, offering enhanced control and precision during the packaging process.

Key Features and Benefits:

1. Enhanced Control: The advanced tilter provides precise control over the mattress positioning, ensuring accurate alignment for compression, folding, and rolling. This feature eliminates any potential misalignment issues that may affect the overall packaging quality.

2. Adjustable Tilt Angle: The tilter allows operators to adjust the tilt angle according to specific packaging requirements. This flexibility enables customization for different mattress sizes, shapes, and thicknesses, ensuring optimal packaging efficiency.

3. Smooth and Safe Operation: The tilter is equipped with advanced hydraulic or pneumatic systems that guarantee smooth and controlled tilting movements. This ensures the safety of both operators and the mattress, preventing any potential damage during the packaging process.

4. Integrated Sensor Technology: The tilter incorporates sensor technology to detect and adjust the tilt angle automatically. This feature eliminates the need for manual adjustments and ensures consistent packaging quality throughout the operation.

5. Easy Integration: The tilter is specifically designed to seamlessly integrate with the 1390HCB Automatic Mattress Packaging machine. Its compact design and easy installation process ensure minimal downtime during integration, maximizing productivity.

6. User-Friendly Interface: The tilter is equipped with a user-friendly interface that allows operators to monitor and adjust the tilting process effortlessly. The interface provides real-time feedback on the packaging progress, making it easy to identify and address any issues promptly.

Conclusion:

The advanced tilter for the 1390HCB Automatic Mattress Packaging machine enhances the packaging process by providing enhanced control, adjustable tilt angles, smooth operation, integrated sensor technology, easy integration, and a user-friendly interface. This tilter ensures precise alignment and efficient packaging, resulting in high-quality compressed, single fold, and roll packed mattresses. With this advanced tilter, the 1390HCB becomes an even more versatile and reliable solution for the mattress packaging industry. Automatic Packing Line

#1390HCB #Automatic #Mattress #Packaging #Compression #Single #Fold #Roll #Pack