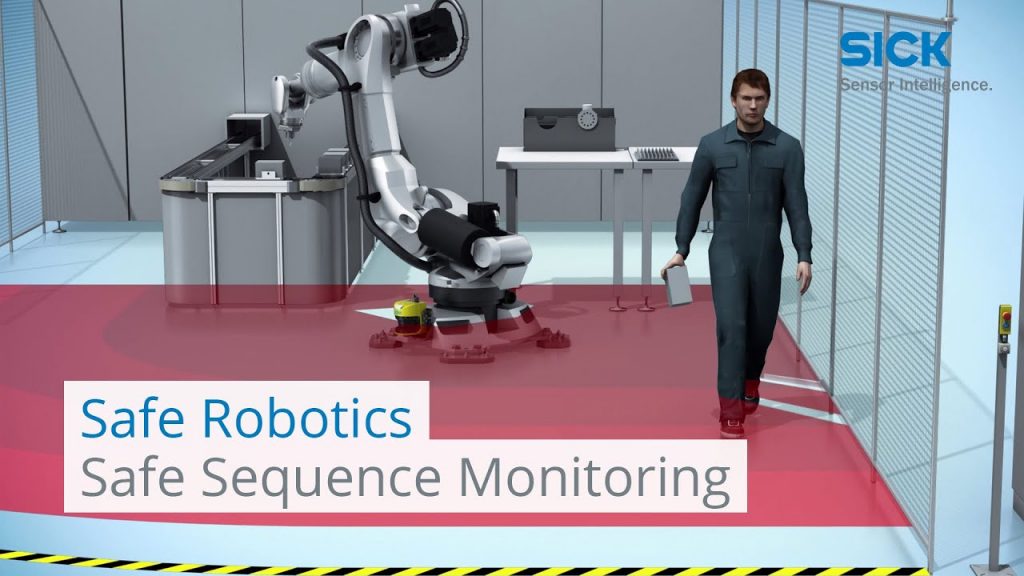

In this YouTube video article, we will delve into the realm of Industrial Robot Safety and specifically focus on Safe Sequence Monitoring, a groundbreaking innovation from SICK AG. With a flexible and efficient approach, Safe Sequence Monitoring ensures a secure collaboration between humans and robots in various industrial settings.

Industrial Robot Safety has always been a paramount concern in the manufacturing industry. The integration of robots into the production process offers numerous benefits, such as increased efficiency and productivity. However, it also poses potential risks to human workers. To address this challenge, SICK has developed Safe Sequence Monitoring, a comprehensive solution that ensures the safety of both humans and robots working side by side.

Safe Sequence Monitoring employs advanced technology to monitor and control the movement of robots in real-time. By continuously analyzing the sequence of operations, this innovative system can detect any deviations or anomalies that might jeopardize the safety of the human operators. In such cases, the system intervenes to halt the robot's movement immediately, preventing any potential accidents or injuries.

One of the key advantages of Safe Sequence Monitoring is its flexibility. The system can be easily customized to suit the specific requirements of different industrial applications. Whether it's a high-speed production line or a collaborative workspace, Safe Sequence Monitoring adapts effortlessly to ensure optimal safety standards are maintained at all times.

The implementation of Safe Sequence Monitoring not only protects human workers but also enhances the overall efficiency of the production process. With the confidence that their safety is assured, employees can work more effectively alongside robots, leading to improved productivity and output. Furthermore, the reduction in accidents and downtime results in significant cost savings for the company.

Safe Robotics is an essential aspect of the future of manufacturing. As automation continues to evolve, it is crucial to prioritize the safety of human workers. SICK AG's Safe Sequence Monitoring system stands at the forefront of this development, providing a reliable and efficient solution for Industrial Robot Safety.

In conclusion, Safe Sequence Monitoring from SICK AG offers a revolutionary approach to Industrial Robot Safety. By ensuring a secure collaboration between humans and robots, this innovative system enhances productivity while safeguarding the well-being of workers. As automation becomes increasingly prevalent in the manufacturing industry, investing in advanced safety measures like Safe Sequence Monitoring is essential for a successful and secure future.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

"Enhancing Safety in Robotics: Ensuring Secure Sequence Monitoring and Industrial Robot Safety"