Check out the leading manufacturer for professional coil packing solutions here:

---

Title: Enhance Efficiency and Safety with Collision Guard Software for Industrial Automation Robots

Introduction:

In today's fast-paced industrial landscape, automation has become a necessity for businesses seeking to improve productivity and reduce costs. FANUC Robotics, Inc., a market leader in Industrial Automation Robots, offers a comprehensive range of cutting-edge solutions to streamline operations. One such solution is their Collision Guard software, designed to ensure enhanced safety and efficiency in robot applications. In this article, we will delve into the features and benefits of Collision Guard software, highlighting its role in revolutionizing the industrial automation industry.

Section 1: The Need for Industrial Automation Robots

Industrial automation robots have become indispensable in various sectors, including manufacturing, logistics, and automotive. These robots offer increased precision, speed, and reliability, leading to improved productivity and reduced human error. With the rising demand for flexible and automated production processes, the need for robust and reliable collision detection and prevention technology has become critical.

Section 2: Introducing FANUC Robotics and Collision Guard Software

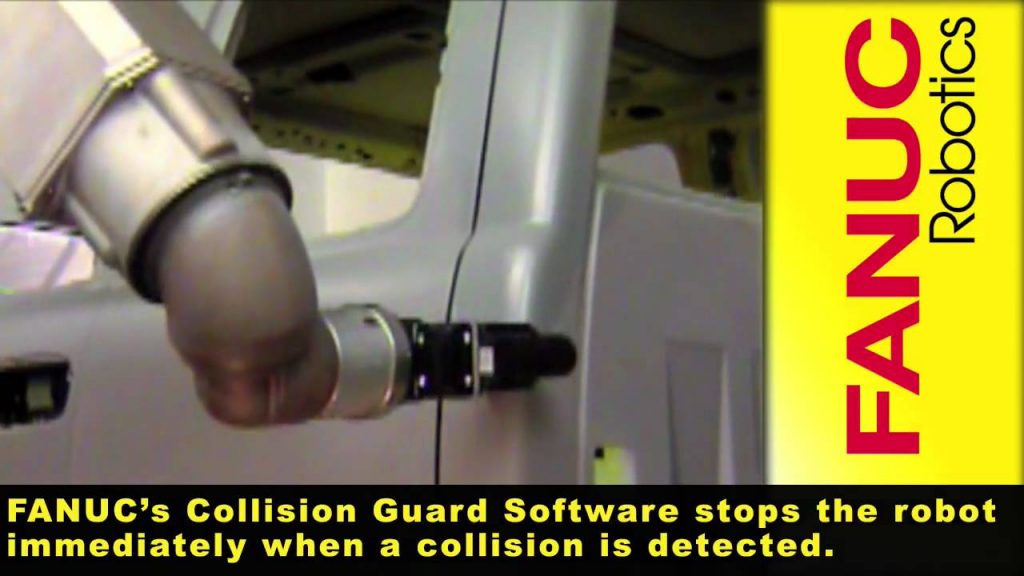

FANUC Robotics, Inc. is renowned for its expertise in developing advanced automation solutions. Their Collision Guard software is specifically designed to minimize the risk of collisions between robots, workpieces, and peripheral equipment. By combining state-of-the-art vision technology and intelligent algorithms, Collision Guard ensures a safe and efficient working environment for automated systems.

Section 3: Features and Benefits of Collision Guard Software

3.1 Advanced Vision-Based Collision Detection:

Collision Guard software utilizes advanced vision-based algorithms to detect potential collisions accurately. By analyzing real-time images captured by cameras integrated into the robot system, Collision Guard can identify any impending collision and trigger immediate corrective actions.

3.2 Real-Time Monitoring and Response:

With Collision Guard, operators can monitor the entire robot system in real-time. The software continuously evaluates the robot's position, speed, and trajectory, comparing them with predefined safety parameters. If an anomaly or potential collision is detected, Collision Guard instantly initiates safety measures, such as reducing robot speed or bringing the robot to a complete stop.

3.3 Flexibility and Customization:

Collision Guard software is highly versatile and can be tailored to specific industrial automation applications. Users can define their own safety zones, establish speed limits, and customize response actions according to their unique requirements. This flexibility ensures seamless integration of Collision Guard into existing automation systems.

Section 4: Case Study: Enhancing Safety and Efficiency with Collision Guard

To illustrate the practical benefits of Collision Guard software, let's consider a case study involving a manufacturing facility. Company XYZ, a leading automotive component manufacturer, implemented FANUC Robotics' Collision Guard software in their production line. The software enabled real-time collision detection and prevention, significantly reducing the risk of accidents and equipment damage. As a result, XYZ experienced a 20% increase in productivity and a notable decrease in downtime.

Section 5: The Future of Collision Guard and Industrial Automation Robots

As the industrial automation industry continues to evolve, Collision Guard software is expected to play a pivotal role in ensuring safe and efficient robot applications. Advancements in artificial intelligence and machine learning will further enhance the capabilities of Collision Guard, enabling even more accurate collision detection and preventive measures. With ongoing research and development, FANUC Robotics remains committed to pushing the boundaries of industrial automation safety.

Conclusion:

Collision Guard software from FANUC Robotics is revolutionizing the way industrial automation robots operate. By providing advanced collision detection and prevention capabilities, this software ensures a safe and efficient working environment. Whether it's in manufacturing, logistics, or automotive industries, Collision Guard enhances productivity, minimizes downtime, and safeguards valuable assets. Embrace the future of industrial automation with Collision Guard software and experience the transformative power it brings to your operations.

---

Check out the leading manufacturer for professional coil packing solutions here: [Insert URL] Industrial Robot

"Maximizing Safety and Efficiency with P-200 Collision Guard: Unleashing the Power of Industrial Automation Robots"