Check out our website for more information on the leading manufacturer of coil packing solutions.

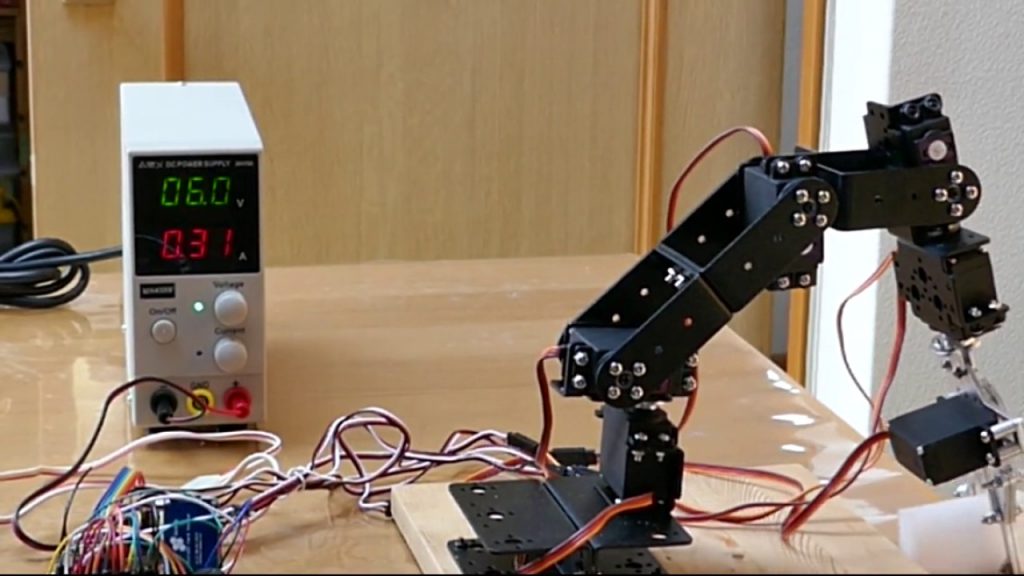

Title: Unlocking the Potential of Industrial Robotic Arms: This Robot Can Learn How to Move by Learning Mode

Introduction:

In the world of robotics, the capabilities of machines continue to evolve and push boundaries. One such innovation is the Industrial Robotic Arm, a cutting-edge technology that is revolutionizing the manufacturing industry. In this article, we will explore the incredible capabilities of a robot that can learn how to move through learning mode, thanks to the powerful Arduino-nano controller. Join us as we delve into the fascinating world of Industrial Robotic Arms and their potential for transforming the manufacturing landscape.

Section 1: The Power of Learning Mode

Imagine a robot that can adapt and learn new movements, no matter how complex or lengthy the process. This is made possible through learning mode, a feature that enables the Industrial Robotic Arm to acquire new skills and movements. With the assistance of an Arduino-nano controller, this robot can analyze and understand its surroundings, allowing it to perform tasks with precision and efficiency.

Section 2: Unleashing the Potential of the Arduino-nano Controller

The Arduino-nano controller serves as the brain behind the Industrial Robotic Arm. This powerful device enables the robot to process information, make decisions, and execute tasks seamlessly. By leveraging the capabilities of the Arduino-nano controller, the Industrial Robotic Arm becomes a versatile and adaptable machine, capable of performing a wide range of tasks with incredible accuracy.

Section 3: The Versatility of the Industrial Robotic Arm

One of the key features of the Industrial Robotic Arm is its flexibility and versatility. With its 6 degrees of freedom (DOF), this robot arm can move in any direction and perform complex tasks with ease. Whether it's picking and placing objects, assembling components, or performing intricate maneuvers, the Industrial Robotic Arm can handle it all.

Section 4: The Analytical Power of Industrial Robotic Arms

Industrial Robotic Arms are not just powerful tools for physical tasks; they also possess advanced analytical capabilities. These machines can gather data, analyze it in real-time, and make informed decisions based on the information collected. This analytical power allows the Industrial Robotic Arm to optimize its movements, improve efficiency, and enhance overall productivity.

Section 5: Transforming the Manufacturing Landscape

The integration of Industrial Robotic Arms into manufacturing processes has the potential to revolutionize the industry. These machines can significantly increase production speed, reduce errors, and improve overall efficiency. With their ability to learn and adapt, Industrial Robotic Arms can be programmed to perform complex tasks that were once only possible for human workers. This not only enhances productivity but also ensures worker safety by minimizing the risk of accidents in hazardous environments.

Conclusion:

The Industrial Robotic Arm, with its learning mode and Arduino-nano controller, exemplifies the cutting-edge capabilities of modern robotics. As we continue to explore the possibilities of this technology, it is clear that Industrial Robotic Arms have the potential to transform the manufacturing industry. With their analytical power, versatility, and adaptability, these machines are paving the way for a more efficient and productive future. Embrace the power of Industrial Robotic Arms and unlock new possibilities for your manufacturing processes.

Check out our website for more information on the leading manufacturer of coil packing solutions. Industrial Robot

"Optimizing Precision and Efficiency: Unleashing the Potential of 6 DOF and Industrial Robotic Arms"