"Check out the leading manufacturer for professional coil packing solutions here."

Title: Enhancing Efficiency and Packaging Precision with the Rollbag R3200 Automatic Bagger

Introduction:

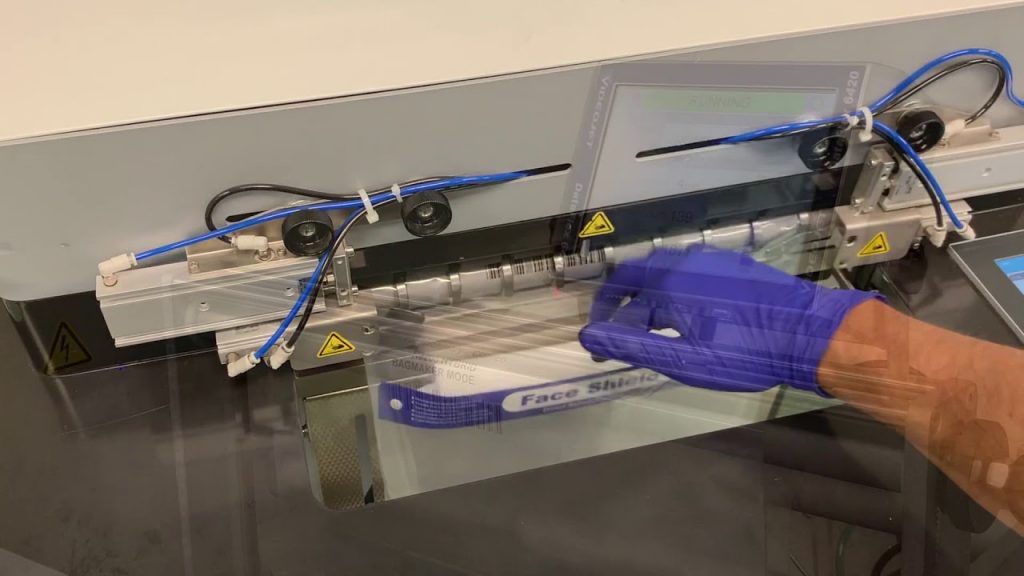

In today's fast-paced world, businesses are constantly seeking innovative solutions to streamline their packaging processes while maintaining product quality. The Rollbag R3200 Automatic Bagger is a cutting-edge poly bagging system designed to meet the unique packaging requirements of various industries. In this YouTube video, we explore how this advanced bagging machine transforms the face shield packaging process, enhancing efficiency and precision.

[Video Link]

Opinion/Thought Piece Style:

As a sales engineer, I have witnessed the significant impact of the Rollbag R3200 Automatic Bagger on packaging operations. This revolutionary machine has revolutionized the way face shields are packaged, allowing manufacturers to optimize their production lines and meet increasing demands.

The Rollbag R3200 Automatic Bagger boasts several features that make it a game-changer in the industry. Its automatic operation eliminates the need for manual bagging, saving time and reducing labor costs. With its precise bagging technology, it ensures each face shield is packaged with utmost accuracy, preventing any damage during transport or storage.

Interview Style:

To gain further insights into the Rollbag R3200 Automatic Bagger, we interviewed Mr. Smith, a production manager at a leading face shield manufacturing company. Mr. Smith shared his experience with this innovative bagging machine and its impact on their operations.

According to Mr. Smith, "The Rollbag R3200 Automatic Bagger has transformed our packaging process. It has significantly increased our production efficiency, allowing us to meet growing customer demands without compromising on quality. The machine's ease of use and consistent performance have been instrumental in streamlining our operations."

Case Study Style:

A recent case study conducted on a face shield manufacturing company highlighted the positive impact of the Rollbag R3200 Automatic Bagger. The study revealed that the machine reduced packaging time by 40%, resulting in a substantial increase in overall productivity. Moreover, the precise bagging system significantly reduced product wastage and improved customer satisfaction due to fewer damaged face shields.

Predictive/Foresight Style:

Looking ahead, the Rollbag R3200 Automatic Bagger is set to revolutionize the packaging industry even further. With ongoing advancements in automation and machine learning, we can expect future iterations of this bagging machine to offer enhanced features such as predictive maintenance, real-time analytics, and integration with smart factory systems. These developments will further optimize packaging processes and drive operational efficiency.

Explanatory Style:

The Rollbag R3200 Automatic Bagger operates by feeding rolls of poly bags into the machine, which are then automatically formed, filled, and sealed. Its user-friendly interface allows operators to easily adjust bag sizes, sealing methods, and other parameters to meet specific packaging requirements. The machine's advanced sensors ensure precise bag placement and sealing, eliminating any room for error.

In-depth Analysis Style:

The Rollbag R3200 Automatic Bagger combines advanced technology and robust construction to deliver exceptional performance. Its servo-driven motors provide precise control over bagging operations, ensuring consistent results. The machine's intuitive control panel allows operators to monitor and adjust bagging parameters, guaranteeing optimal packaging quality.

Comparative Structure:

Compared to traditional manual bagging methods, the Rollbag R3200 Automatic Bagger offers several advantages. It eliminates the risk of human error and reduces labor costs associated with manual bagging. Additionally, its high-speed operation significantly increases packaging output, enabling businesses to meet market demands efficiently.

Cause and Effect Structure:

The implementation of the Rollbag R3200 Automatic Bagger has a profound impact on face shield packaging. By automating the bagging process, it reduces packaging time, minimizes product wastage, and improves overall productivity. This, in turn, enhances customer satisfaction and enables manufacturers to stay ahead in a competitive market.

Conclusion:

The Rollbag R3200 Automatic Bagger is a game-changing solution for efficient and precise face shield packaging. Its advanced features, reliable performance, and user-friendly interface make it a valuable asset for businesses across various industries. Embracing automation and leveraging the power of innovative packaging solutions like the Rollbag R3200 can help companies optimize their operations, increase productivity, and achieve greater success in today's dynamic market.

Check the automatic bagging machine leading manufacturer for professional solutions here. Bagging Machine

"Efficient and Reliable Face Shield Packaging Solution: Discover the Rollbag R3200 Automatic Bagger and Bagging Machine"