Check out the leading manufacturer for the professional coil packing solution here:

Title: Enhance Efficiency and Speed with the Kt Pack APC 35 Vertical Bagging Machine

Introduction:

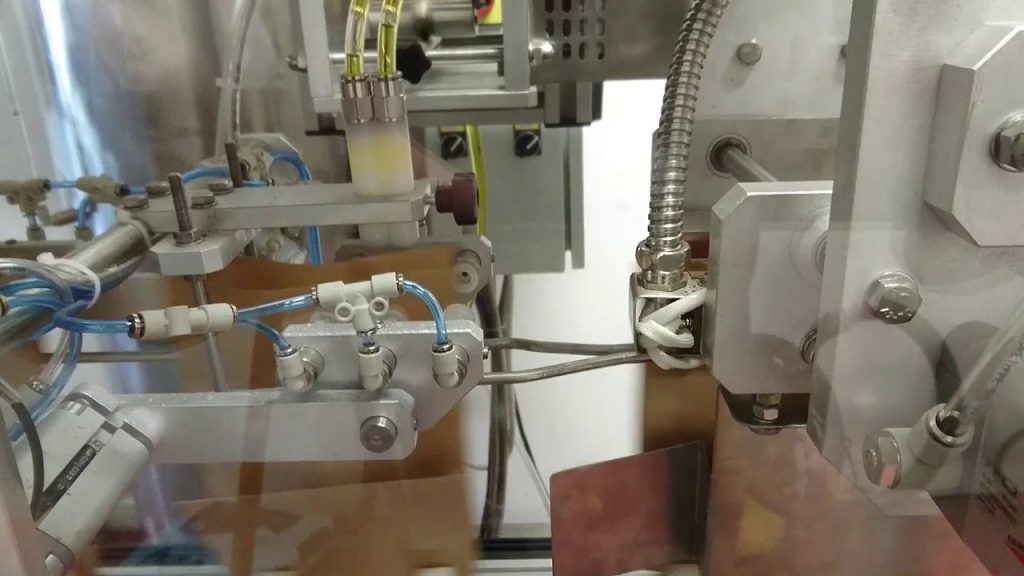

In the fast-paced world of popcorn production, having a reliable and efficient bagging machine is crucial. The Kt Pack Model APC 35 Vertical Bagging Machine is a game-changer in the industry. With its impressive speed of 28 units per minute and innovative features such as corn supply shears, this popcorn microwave bagger is a must-have for any popcorn manufacturer. In this article, we will delve into the features and benefits of the Kt Pack APC 35 and explore its impact on the popcorn production process.

Section 1: Introduction to the Kt Pack APC 35 Vertical Bagging Machine

- Briefly introduce the Kt Pack APC 35 Vertical Bagging Machine and its key specifications, including its year of manufacture (2015) and impressive speed of 28 units per minute.

- Explain the significance of the corn supply shears, which contribute to the machine's efficiency and productivity.

- Highlight the importance of choosing a reliable and high-quality bagging machine for popcorn production.

Section 2: The Advantages of the Kt Pack APC 35 Vertical Bagging Machine

- Discuss how the Kt Pack APC 35 enhances efficiency and speed in the popcorn production process.

- Explore the benefits of its vertical bagging design, which allows for seamless integration into existing production lines.

- Emphasize the machine's ability to handle a high volume of bags, ensuring uninterrupted production.

- Highlight the durability and reliability of the Kt Pack APC 35, leading to minimal downtime and maintenance.

Section 3: The Role of Vertical Bagging Machines in Popcorn Production

- Provide an overview of the importance of bagging machines in the popcorn production industry.

- Explain how vertical bagging machines, like the Kt Pack APC 35, streamline the bagging process, resulting in increased productivity and reduced labor costs.

- Discuss the versatility of vertical bagging machines, which can be used for various popcorn flavors and sizes.

- Touch upon the impact of bagging machines on product presentation and customer satisfaction.

Section 4: Case Study: Implementing the Kt Pack APC 35 Vertical Bagging Machine

- Present a real-world case study of a popcorn manufacturer who integrated the Kt Pack APC 35 into their production line.

- Discuss the challenges they faced before the implementation and how the Kt Pack APC 35 addressed those challenges.

- Highlight the improvements in efficiency, speed, and overall production output after incorporating the bagging machine.

- Share testimonials from the manufacturer, highlighting their satisfaction with the Kt Pack APC 35.

Section 5: The Future of Vertical Bagging Machines and Technology Advancements

- Discuss the potential advancements in bagging machine technology, such as automation and smart features.

- Highlight the role of artificial intelligence and machine learning in optimizing bagging processes.

- Predict the future trends in the popcorn production industry and how vertical bagging machines like the Kt Pack APC 35 will adapt to meet these demands.

Conclusion:

The Kt Pack APC 35 Vertical Bagging Machine revolutionizes the popcorn production process with its exceptional speed, corn supply shears, and vertical bagging design. Its impact on efficiency, productivity, and overall customer satisfaction cannot be overstated. As the industry continues to evolve, the Kt Pack APC 35 sets the standard for bagging machines. Upgrade your popcorn production line today and experience the benefits of this state-of-the-art vertical bagging machine.

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert relevant CTA or link to the manufacturer's website] Bagging Machine

"Efficient Sachet and Vertical Bagging Machine: Boost Productivity with the Kt Pack APC 35"