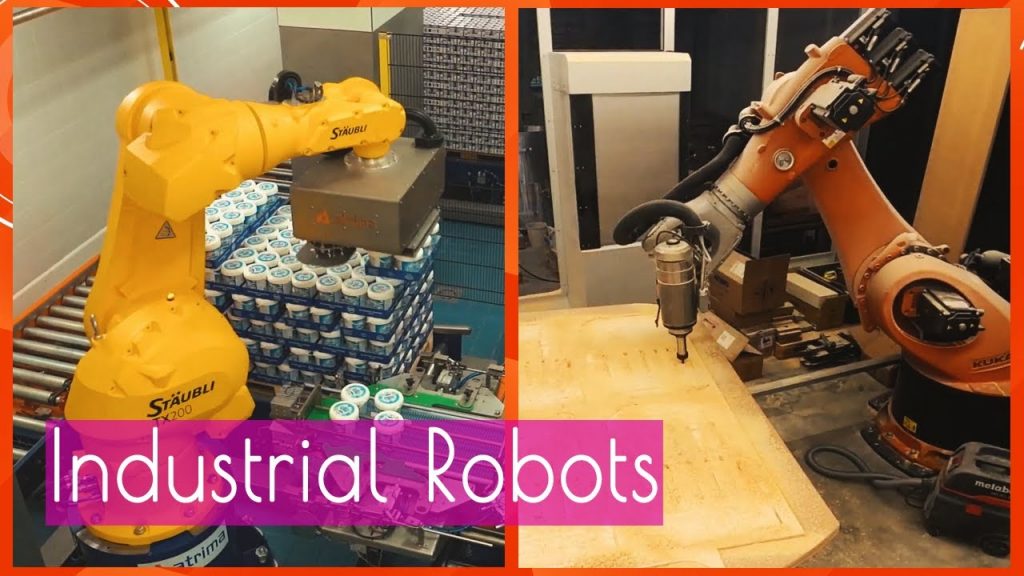

Welcome to our YouTube video on the Overview of the most popular type of modern industrial robot - the manipulator arm. In this video, we will explore the different types of work performed by manipulator arms and discuss the various types of industrial robots available in the market today.

Industrial robots have revolutionized the manufacturing industry by automating various tasks and improving efficiency. One of the most common types of industrial robots is the manipulator arm. These robots are designed to mimic the movement of a human arm and can perform a wide range of tasks.

One of the key advantages of manipulator arms is their versatility. They can be programmed to perform different tasks such as picking and placing objects, welding, painting, and assembly. This makes them suitable for a wide range of industries including automotive, electronics, and food and beverage.

Let's take a closer look at the different types of industrial robots:

1. Cartesian Robots: These robots have three linear joints that allow movement along the X, Y, and Z axes. Cartesian robots are known for their precision and are often used for tasks that require high accuracy.

2. SCARA Robots: SCARA stands for Selective Compliance Assembly Robot Arm. These robots have a rigid structure and are commonly used for assembly line tasks that require fast and precise movements.

3. Articulated Robots: These robots have multiple rotary joints that allow for greater flexibility and range of motion. They are often used for tasks that require complex movements such as welding or painting.

4. Delta Robots: Delta robots are known for their high speed and precision. They are typically used for tasks that require fast and repetitive movements, such as packaging or sorting.

5. Collaborative Robots: Also known as cobots, these robots are designed to work alongside humans. They have built-in safety features that allow them to operate in close proximity to humans without causing harm. Cobots are often used for tasks that require human-robot collaboration, such as assembly or inspection.

Industrial robots offer numerous benefits to manufacturers. They can increase productivity, improve product quality, and reduce production costs. With advancements in technology, robots are becoming more intelligent and capable of performing complex tasks.

In conclusion, the manipulator arm is one of the most popular types of industrial robots due to its versatility and ability to perform a wide range of tasks. From Cartesian robots to collaborative robots, there is a robot for every industry and application.

Check the coil packing solution with leading manufacturers for professional solutions. Industrial Robot

"Unveiling the Versatility of Industrial Robots: Exploring Their Capabilities and Various Types"