Title: Packaging Line Automation and Totally Integrated Automation - End-of-line Packaging Machine | Siemens at Hannover Messe 2014

Description:

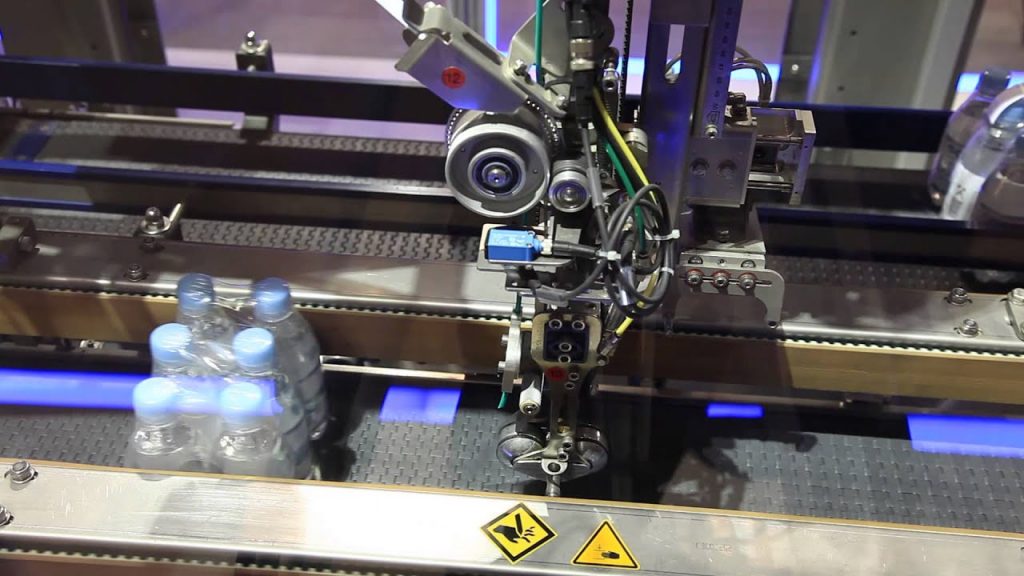

Welcome to our YouTube video showcasing the innovative Packaging Line Automation and Totally Integrated Automation systems presented by Siemens at Hannover Messe 2014. In the Engineering sector, we are proud to demonstrate the cutting-edge advancements in end-of-line packaging machines and their integration with Siemens' state-of-the-art automation solutions.

Throughout this video, you will witness the seamless collaboration between Siemens' advanced technologies and the packaging industry. We delve into the comprehensive features and benefits of Packaging Line Automation, emphasizing its role in optimizing production processes, enhancing efficiency, and ensuring product quality.

Our experts will guide you through the intricate details of Totally Integrated Automation, which seamlessly integrates various manufacturing processes, including labeling, filling, sealing, and palletizing. Witness how this holistic approach streamlines operations and maximizes productivity, ultimately leading to significant cost savings for businesses.

Highlighting key takeaways, we discuss the operation steps involved in implementing Packaging Line Automation and Totally Integrated Automation, providing valuable insights for professionals in the field. Discover the advantages of these systems, such as enhanced flexibility, precise control, and real-time monitoring, all of which contribute to a highly efficient and reliable packaging process.

We invite you to like, subscribe, and share this video to stay updated on the latest trends and advancements in packaging automation. By doing so, you will be part of our growing community of industry enthusiasts, gaining access to exclusive content and future updates.

Additional Tags: Packaging Line Automation, Totally Integrated Automation, end-of-line packaging machine, Siemens, Hannover Messe 2014, engineering, automation solutions, production processes, efficiency, product quality, manufacturing processes, labeling, filling, sealing, palletizing, flexibility, control, real-time monitoring.

Hashtags: #PackagingAutomation #IntegratedAutomation #Siemens #HannoverMesse #Engineering #AutomationSolutions

A tilter is a device used in end-of-line packaging machines to tilt products or packages for various purposes, such as stacking, sorting, or inspecting. In the context of Totally Integrated Automation (TIA) - End-of-line packaging machine, the tilter can be controlled and automated through a TIA system. Here is an example of a tilter for such a machine:

```python

import time

class Tilter:

def __init__(self):

self.status = "idle" # Current status of the tilter

def tilt(self, angle):

self.status = "tilting"

print(f"Tilter: Tilted at {angle} degrees")

time.sleep(2) # Simulating the tilting process

self.status = "idle"

def get_status(self):

return self.status

# Example usage

if __name__ == "__main__":

tilter = Tilter()

print(f"Tilter Status: {tilter.get_status()}") # idle

tilter.tilt(45) # Tilt at 45 degrees

print(f"Tilter Status: {tilter.get_status()}") # idle

```

In this example, a `Tilter` class is created with an `__init__` method to initialize the tilter's status as "idle". The `tilt` method simulates the tilting process by waiting for 2 seconds and updating the tilter's status accordingly. The `get_status` method allows retrieving the current status of the tilter.

In the main section, an instance of the `Tilter` class is created, and its status is printed (which should be "idle" initially). Then, the `tilt` method is called to tilt the tilter at a specified angle (e.g., 45 degrees). After the tilting process is completed, the updated status is printed.

This tilter can be integrated into a Totally Integrated Automation system for end-of-line packaging machines, allowing seamless control and automation of the tilter's functionality. Automatic Packing Line

#Totally #Integrated #Automation #Endofline #packaging #machine