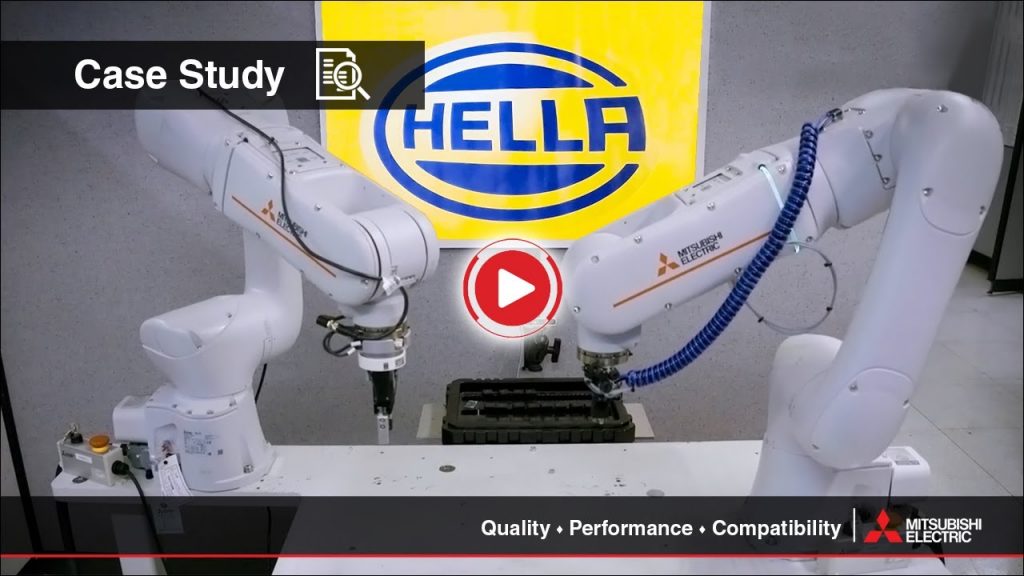

Check out our video on Industrial Robot Safety to learn how Hella Electronics Corporation partnered with Mitsubishi Electric Automation and Realtime Robotics to develop a unique solution for improving safety and efficiency in their manufacturing processes.

In today's fast-paced and ever-evolving industrial landscape, the safety of workers and the efficiency of operations are of paramount importance. With the rise of robotics and automation, companies like Hella Electronics Corporation are constantly seeking innovative ways to enhance their production capabilities while ensuring the well-being of their employees.

Hella Electronics Corporation, a leading global supplier of automotive lighting and electronics, recognized the need to address industrial robot safety in their manufacturing facilities. They understood that collaborative robots, also known as cobots, were the future of safe and efficient manufacturing. Collaborative robots are designed to work alongside humans, minimizing the risk of accidents and injuries.

To achieve their goal of implementing industrial robot safety, Hella Electronics Corporation turned to Mitsubishi Electric Automation and Realtime Robotics. Mitsubishi Electric Automation is a renowned provider of automation solutions, while Realtime Robotics specializes in motion planning technology for robots. Together, they formed a strategic partnership to develop a cutting-edge solution tailored to Hella Electronics Corporation's specific needs.

The collaboration between Hella Electronics Corporation, Mitsubishi Electric Automation, and Realtime Robotics resulted in the successful implementation of a unique system that improved both safety and efficiency in their manufacturing processes. By leveraging collaborative robots and advanced motion planning technology, Hella Electronics Corporation was able to create a safer working environment for their employees.

The integration of collaborative robots allowed Hella Electronics Corporation to automate repetitive and potentially hazardous tasks, such as heavy lifting and assembly. This not only reduced the risk of injuries but also increased productivity and efficiency. The robots were programmed to work in harmony with human operators, with built-in safety features that would immediately halt their movements if they detected any potential danger.

Realtime Robotics' motion planning technology played a crucial role in ensuring the smooth and safe collaboration between humans and robots. By analyzing the environment and generating optimized paths for the robots, the system minimized the risk of collisions and accidents. This advanced technology enabled Hella Electronics Corporation to achieve a higher level of safety and efficiency in their manufacturing processes.

The success of Hella Electronics Corporation's partnership with Mitsubishi Electric Automation and Realtime Robotics serves as a testament to the importance of industrial robot safety in today's manufacturing industry. By prioritizing the well-being of their employees and embracing innovative technologies, companies can create a safer and more productive work environment.

In conclusion, Hella Electronics Corporation's collaboration with Mitsubishi Electric Automation and Realtime Robotics has led to the development of a groundbreaking solution for industrial robot safety. By harnessing the power of collaborative robots and advanced motion planning technology, Hella Electronics Corporation has not only enhanced the safety of their workers but also improved the efficiency of their manufacturing processes. This partnership exemplifies the potential of collaborative robots in revolutionizing the industrial landscape.

Check out the video above to learn more about Hella Electronics Corporation's journey towards industrial robot safety and how their partnership with Mitsubishi Electric Automation and Realtime Robotics has transformed their manufacturing processes.

### Check the coil packing solution with leading manufacturer for the professional solution just here: Industrial Robot

Enhancing Safety and Efficiency: Collaborative Robots in Electronics and Industrial Settings