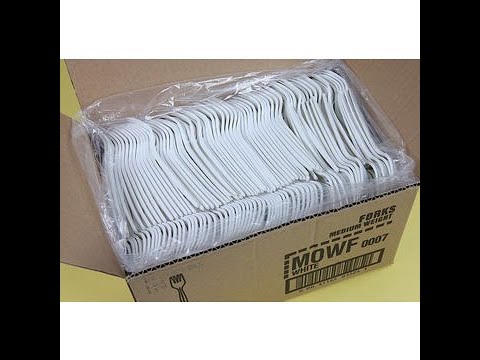

If you are looking to increase production and save on labor costs, while also ensuring the safety and hygiene of your products, then the complete line of Automatic Packing Systems is the perfect solution for you. In this YouTube video article, we will explore the various benefits and features of these systems, as well as their relevance to the plastic fork spoon making automatic packing machine tableware injection molding machine.

The Automatic Packing System is designed to streamline and automate the packaging process, eliminating the need for manual labor and reducing the risk of contamination. With this system, you can expect a significant increase in production efficiency, as it can handle large volumes of products at a much faster rate than manual packing methods. This not only saves time but also allows you to meet the demands of your customers more effectively.

One of the key advantages of the Automatic Packing System is its ability to prevent direct contact between hands and the products. This is especially important in industries where hygiene and safety are paramount, such as the food and pharmaceutical industries. By eliminating the need for human touch during the packing process, you can ensure that your products remain clean and uncontaminated, reducing the risk of product recalls and customer dissatisfaction.

Furthermore, the system is designed to be user-friendly and easy to operate. With its intuitive interface and automated features, even non-technical personnel can efficiently manage the packing process. This not only saves on labor costs but also minimizes the risk of human error, ensuring consistent quality and accuracy in every pack.

In terms of the plastic fork spoon making automatic packing machine tableware injection molding machine, the Automatic Packing System offers seamless integration. It is specifically designed to work in tandem with these machines, providing a complete end-to-end solution for your production line. This means that you can achieve a fully automated workflow, from the injection molding of the tableware to the final packing and sealing of the products.

With the Automatic Packing System, you can expect a range of features tailored to your specific needs. These may include automatic product feeding, precise bagging and sealing, as well as customizable options for labeling and coding. The system can also be easily adjusted to accommodate different product sizes and packaging requirements, making it a versatile solution for various industries.

In conclusion, the Automatic Packing System not only increases production efficiency and saves on labor costs but also offers enhanced safety and hygiene for your products. Its seamless integration with the plastic fork spoon making automatic packing machine tableware injection molding machine ensures a complete and efficient production line. So, if you are looking for a professional and reliable solution for your packaging needs, look no further than the leading manufacturer of Automatic Packing Systems. Check their coil packing solution now and experience the benefits for yourself. Packing System

"Efficient Automatic Packing System for Plastic Fork and Spoon Making: Tableware Injection Molding Machine & Packaging Solution"