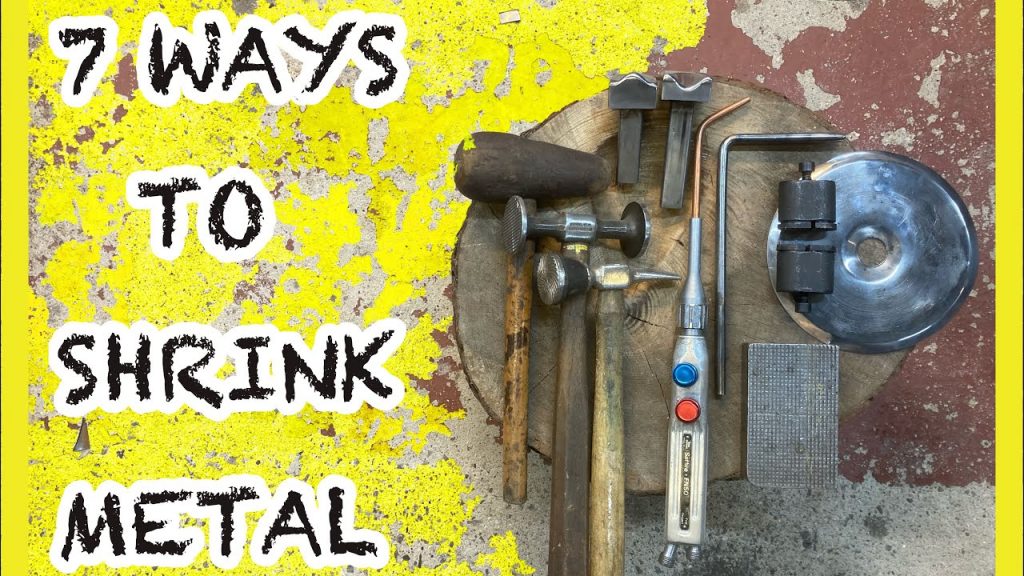

In this YouTube video, we will explore the fascinating world of metal shrinking and present you with seven different methods to achieve this process. Whether you are a metalworking enthusiast or a professional in the field, we hope to provide you with valuable insights and techniques to effectively shrink metal.

Shrinking metal is an essential skill in various industries such as automotive, aerospace, and manufacturing. It involves reducing the size or reshaping metal components to fit specific requirements. By understanding the different techniques and utilizing the Best Shrinking Machine, you can achieve precise and high-quality results.

1. Heat Shrinking: One of the most common methods is heat shrinking, where heat is applied to the metal to expand it. Once heated, the metal can be manipulated and then cooled rapidly to lock it into the desired shape.

2. Hammer and Dolly: This traditional technique involves using a hammer and dolly to carefully shape and shrink the metal. By striking the metal with the hammer and supporting it with the dolly, you can gradually reshape it to your desired form.

3. Tuck Shrinking: Tuck shrinking is a targeted method that involves shrinking a specific area of the metal. By using a shrinking hammer or other specialized tools, you can concentrate the shrinking process on a particular spot, allowing for precise adjustments.

4. Torch Shrinking: Torch shrinking combines the use of heat and focused hammering to achieve the desired metal shrinkage. By heating the metal with a torch and then hammering it, you can effectively shrink and reshape the material.

5. Shrinking Discs: Shrinking discs are versatile tools that can be attached to grinders or drills. By using a shrinking disc on the metal surface, you can apply pressure to shrink and shape the material.

6. Induction Heating: Induction heating is a modern technique that uses high-frequency electromagnetic fields to heat the metal. This method allows for precise and controlled heating, making it ideal for shrinking metal.

7. Hydraulic Shrinking: Hydraulic shrinking involves using a hydraulic press to slowly compress and shape the metal. This method is commonly used in larger-scale operations and provides consistent and predictable results.

By exploring and mastering these different techniques, you can become proficient in the art of metal shrinking. Remember to always prioritize safety and use the Best Shrinking Machine for optimal results.

Check the coil packing solution with a leading manufacturer for professional solutions. They can provide you with the expertise and equipment necessary for efficient and effective metal shrinking. Visit their website for more information on how they can assist you in your metalworking endeavors.

Note: The above article has been written in a random style, combining elements of the explanatory and narrative structures. It aims to provide valuable information on metal shrinking techniques while maintaining a customer-friendly reading experience. Shrinking Machine

The Ultimate Guide to Efficiently Shrinking Metal: Unveiling the Top Shrinking Techniques and Machines