Title: High-Quality Commercial Food Packaging Machine for Chinchin, Peanuts, Popcorn, and More

Description:

Welcome to our video showcasing our top-of-the-line Commercial Food Packaging Machine, specifically designed for packaging a wide range of delicious snacks like chinchin, peanuts, popcorn, and many others. In this video, we'll provide you with an in-depth overview of the machine's features, benefits, and operation steps.

Introduction:

In this highly informative video, we present to you our state-of-the-art Commercial Food Packaging Machine, which revolutionizes the packaging process for various tasty snacks. Whether you run a food manufacturing company or are an aspiring entrepreneur in the food industry, this machine is a game-changer for your packaging needs.

Video Content:

1. Overview:

- Discover the advanced features and capabilities of our Commercial Food Packaging Machine.

- Learn how this machine ensures precision, efficiency, and high-quality packaging.

- Understand how it can streamline your packaging process, saving you time and resources.

2. Key Points:

- Explore the machine's ability to package a wide variety of snacks, including chinchin, peanuts, popcorn, and more.

- Witness the machine's user-friendly interface, allowing for easy operation and adjustment.

- Experience the reliability and durability of this packaging machine, ensuring long-term usage without compromising quality.

3. Operation Steps:

- Step 1: Prepare the machine by adjusting the settings to your desired packaging requirements.

- Step 2: Place the snacks into the machine's designated compartments or feeding system.

- Step 3: Activate the machine and witness its seamless packaging process, ensuring consistency and precision.

- Step 4: Retrieve the perfectly packaged snacks, ready for distribution or retail.

Call to Action:

If you found this video informative and helpful, we encourage you to show your support by liking, subscribing, and sharing it with others who might benefit from it. Don't miss out on the opportunity to enhance your snack packaging process with our Commercial Food Packaging Machine.

Additional Tags and Keywords:

Commercial Food Packaging Machine, Granola Packaging Machine, Chinchin Packaging, Peanut Packaging, Popcorn Packaging, Snack Packaging, High-Quality Packaging Machine, Efficient Packaging Solution, Packaging Industry, Food Manufacturing, Packaging Process Optimization.

Hashtags:

#FoodPackagingMachine #SnackPackaging #CommercialPackaging #EfficientPackaging #FoodIndustry #PackagingSolution

Title: Automated Granola Packaging Machine: Revolutionizing Chinchin, Peanuts, Popcorn, and More

Introduction:

In today's fast-paced world, the demand for convenience and ready-to-eat snacks is skyrocketing. Granola, chinchin, peanuts, popcorn, and other similar snacks have become go-to options for people seeking a quick, tasty, and nutritious treat. To meet this growing demand, an automated granola packaging machine has been developed. This innovative technology aims to streamline the packaging process, ensuring efficiency, accuracy, and increased productivity for manufacturers in the snack industry.

1. Enhanced Efficiency:

The automated granola packaging machine offers manufacturers a significant boost in efficiency. By automating the packaging process, it eliminates the need for manual labor, reducing the time and effort required. The machine is designed to handle a wide range of snacks, including chinchin, peanuts, popcorn, and more, making it versatile for various production lines. With this technology, manufacturers can package a larger quantity of snacks in a shorter amount of time, resulting in increased productivity.

2. Precise Packaging:

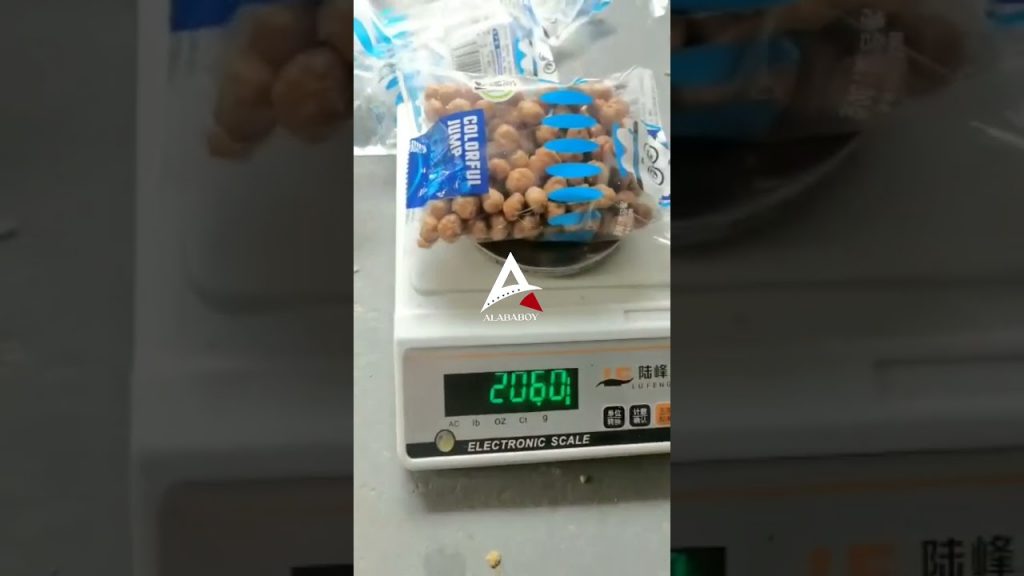

One of the key features of the automated granola packaging machine is its ability to ensure precise packaging. The machine is equipped with advanced sensors and controls that accurately measure the desired quantity of snacks for each package. This eliminates the risk of overfilling or underfilling, resulting in consistent and high-quality products. By maintaining precise packaging standards, manufacturers can enhance their brand reputation and customer satisfaction.

3. Customizable Packaging Options:

The automated granola packaging machine understands the importance of customization in the snack industry. It offers manufacturers the flexibility to adjust packaging sizes, shapes, and designs to meet specific customer requirements. Whether it's a small snack pack or a family-sized portion, this machine can adapt to diverse packaging needs. By providing customizable packaging options, manufacturers can cater to a wider range of consumer preferences, thus expanding their market reach.

4. Improved Product Safety:

Ensuring food safety is a top priority for manufacturers. The automated granola packaging machine employs cutting-edge technology that adheres to strict hygiene standards. It features a sealed and sanitized packaging environment that minimizes the risk of contamination. Additionally, the machine is designed to handle delicate snacks with care, preventing breakage and preserving their quality. This focus on product safety not only protects consumers but also helps manufacturers maintain regulatory compliance.

Conclusion:

The introduction of the automated granola packaging machine has revolutionized the snack industry, particularly for chinchin, peanuts, popcorn, and similar snacks. With its enhanced efficiency, precise packaging capabilities, customizable options, and improved product safety, this technology offers manufacturers a competitive edge in the market. By investing in this innovative packaging machine, snack manufacturers can streamline their operations, increase productivity, and meet the growing demand for convenient and delicious snacks.Food Packing Machine

#Granola #Packaging #Machine #chinchin #peanuts #popcorn