If you're in the packaging industry, you know just how important it is to have efficient and reliable equipment to handle your substrate packaging needs. From infeed to palletizing, every step in the process plays a crucial role in ensuring the quality and integrity of the final product. In this YouTube video, we will explore the various stages of substrate packaging and highlight the key equipment involved, such as the bagging and packaging equipment and the potting soil packaging machine.

Infeed is the initial step in the packaging process, where the substrate is fed into the production line. This can be done manually or through automated systems, depending on the volume and efficiency required. Proper infeed ensures a continuous flow of substrate, minimizing downtime and increasing productivity.

Mixing is the next stage, where different components are blended together to create the desired substrate composition. This is a critical step as it determines the quality and consistency of the final product. Modern mixing equipment ensures accurate measurements and thorough blending, resulting in superior substrates.

Volumetric dosing is another important aspect of substrate packaging. It involves precisely measuring and dispensing specific quantities of the substrate into bags or containers. The accuracy of dosing directly impacts the reliability and efficacy of the end product. Advanced dosing systems guarantee precise measurements, minimizing wastage and maximizing efficiency.

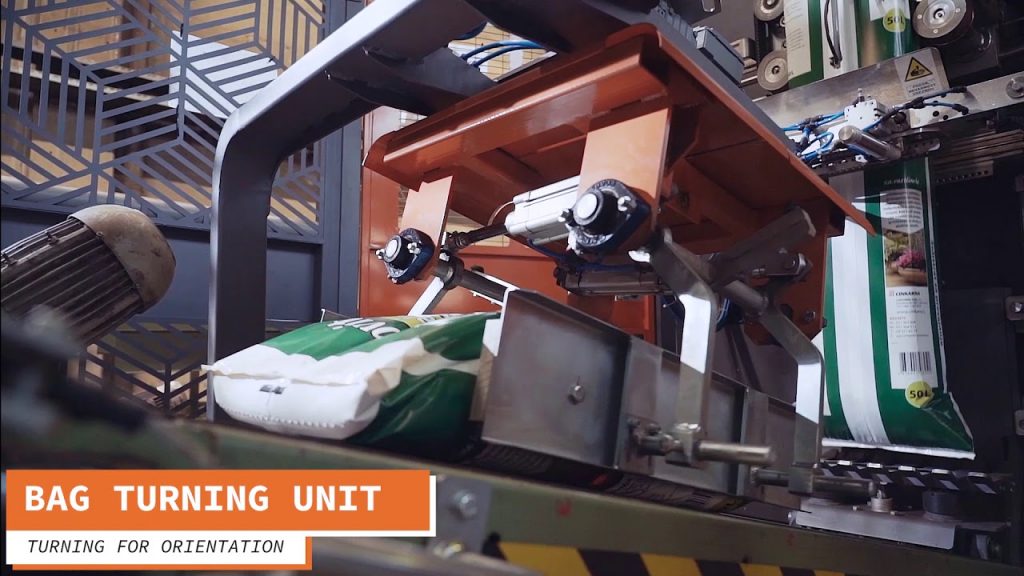

Form fill seal bagging is a widely used packaging method that involves filling bags with substrate and sealing them simultaneously. This automated process ensures consistent bag sizes and secure seals, preventing any contamination or leakage. Bagging equipment is designed to handle various bag types and sizes, providing flexibility and versatility in packaging operations.

Palletizing is the final step in the substrate packaging process, where the bags or containers are arranged on pallets for storage or transportation. Efficient palletizing equipment ensures stable and secure stacking, optimizing space utilization and reducing the risk of damage during handling and transit.

While this video focuses on the aforementioned stages of substrate packaging, it's important to note that there are additional steps involved in the overall packaging process. These include labeling, quality control checks, and logistical considerations. Each aspect plays a crucial role in ensuring a seamless and efficient packaging operation.

In conclusion, the proper selection and utilization of bagging and packaging equipment are essential for successful substrate packaging. From infeed to palletizing, each stage requires specialized machinery to ensure optimum efficiency, accuracy, and product integrity. By investing in reliable equipment, you can streamline your packaging process and deliver high-quality substrates to your customers.

Check out the leading manufacturers of bagging and packaging equipment to find the professional solution you need for your coil packing requirements. With their expertise and advanced technologies, you can elevate your packaging operations to new heights of efficiency and productivity. Bagging Machine

"Efficient Packaging Solutions for Potting Soil: Bagging and Packaging Equipment for Streamlined Production"