Check out our video on the revolutionary Automatic Sorting and Packing System for Strawberries. This state-of-the-art equipment has been developed to align and arrange strawberry fruits at a rate of approximately 7 seconds per fruit, ensuring efficient and accurate packaging.

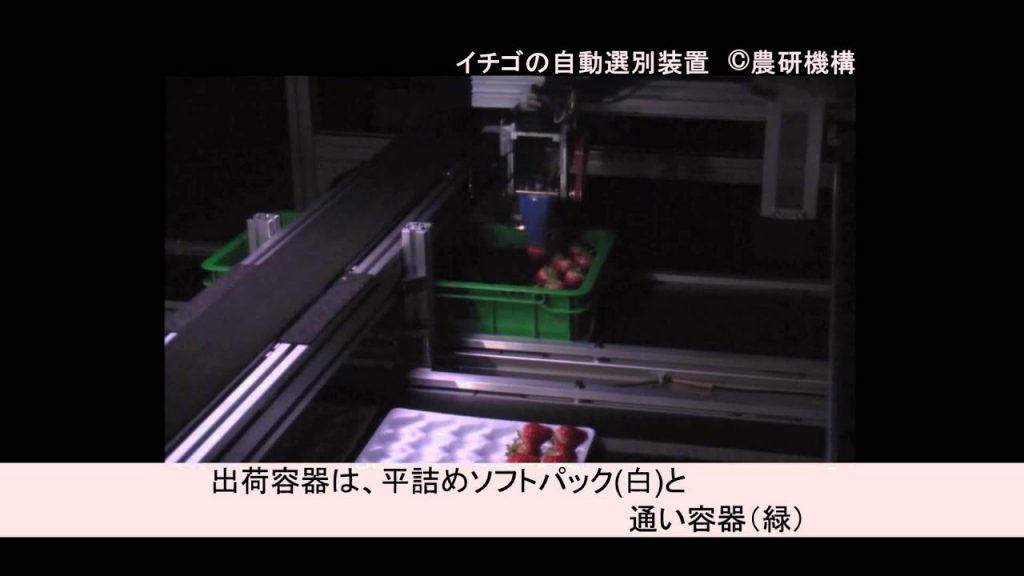

The Automatic Sorting and Packing System consists of two main units - the Supply Unit and the Sorting Unit. Let's delve deeper into how this system works and the benefits it offers for strawberry producers.

The Supply Unit is responsible for feeding the strawberries onto the conveyor belt, where they are transported to the Sorting Unit. This unit utilizes advanced technology to analyze the size, shape, and quality of each fruit in real-time. By using high-resolution imaging and artificial intelligence algorithms, the system can quickly identify any defects or imperfections.

Once the strawberries are analyzed, the Sorting Unit takes over. It employs precision robotic arms to gently handle each fruit, ensuring they are properly aligned and arranged in the packaging containers. This automated process eliminates the need for manual sorting, reducing labor costs and increasing productivity.

The Automatic Sorting and Packing System brings numerous advantages to strawberry producers. Firstly, the high-speed sorting capability allows for a significant increase in production output. With the ability to process a large number of fruits in a short amount of time, growers can meet the demands of their customers more efficiently.

Additionally, the system's accuracy in identifying defects ensures that only the highest quality strawberries are selected for packaging. By eliminating subpar fruits before they reach the market, producers can enhance their brand reputation and customer satisfaction.

Furthermore, the automation of the sorting and packing process reduces human error and minimizes product damage. The delicate nature of strawberries requires careful handling, and the robotic arms of the system guarantee gentle yet efficient packaging, preserving the fruits' integrity.

The Automatic Sorting and Packing System is a game-changer for strawberry producers, providing a reliable, efficient, and cost-effective solution to streamline their operations. By incorporating this technology into their workflow, growers can optimize their resources and maximize their profitability.

In conclusion, the development of the Automatic Sorting and Packing System for Strawberries revolutionizes the strawberry production industry. With its ability to align and arrange strawberry fruits rapidly and accurately, this innovative equipment offers significant advantages for growers. By automating the sorting and packing process, strawberry producers can increase productivity, improve fruit quality, and reduce labor costs. Experience the future of strawberry packaging with this cutting-edge Packing System.

Check out the leading manufacturer for professional coil packing solutions here: [Link to the company's website]. Packing System

"Efficient Sorting and Packaging System for Fresh Strawberries: Revolutionizing the Fruit Industry"