Check out our leading manufacturer for a professional coil packing solution here:

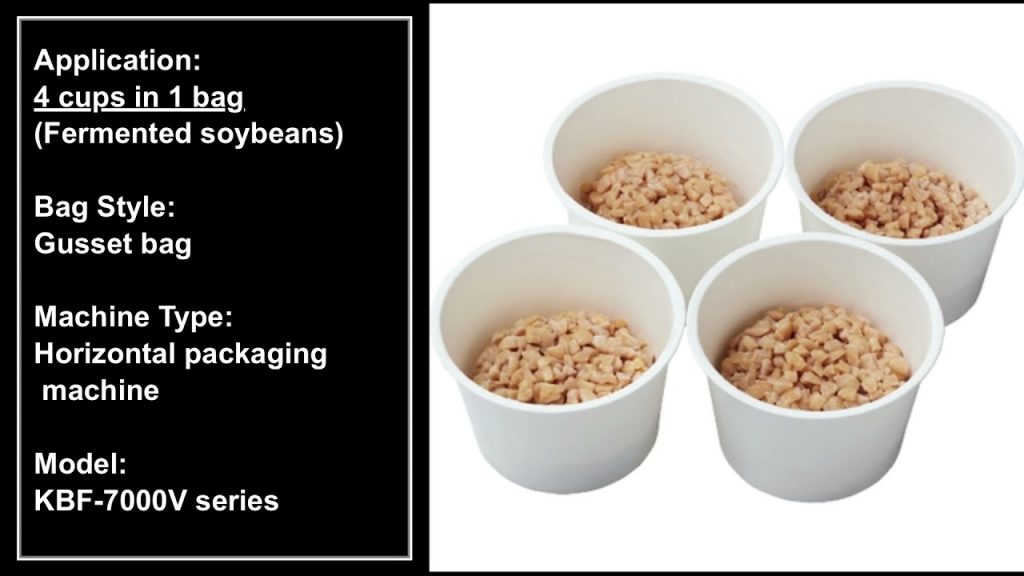

Are you tired of manually packaging your products? Do you want to improve efficiency and save time and labor costs? Look no further! Introducing the KAWASHIMA Horizontal Bagging Machine, your ultimate solution for packaging 4 cups of fermented soybeans in 1 convenient gusset bag.

In this video, we will dive into the various applications of the KAWASHIMA Horizontal Bagging Machine and explore how it revolutionizes the packaging process. Whether you are a small-scale producer or a large manufacturing facility, this machine is designed to meet your needs.

The KAWASHIMA Horizontal Bagging Machine is equipped with state-of-the-art technology that ensures precise and efficient packaging. Its horizontal bagging design allows for easy loading and sealing, providing a secure and attractive packaging solution. With its ability to package 4 cups in 1 bag, you can maximize productivity while minimizing material waste.

But what sets the KAWASHIMA Horizontal Bagging Machine apart from other packaging machines? Let's take a closer look at its key features:

1. Advanced Control System: The machine is equipped with a user-friendly control panel that allows for easy operation and adjustment. You can customize the bag size, sealing time, and other parameters to meet your specific requirements.

2. High-Speed Packaging: With a fast packaging speed of up to X cups per minute, the KAWASHIMA Horizontal Bagging Machine ensures efficient production and meets high-volume demands. Say goodbye to tedious manual packaging!

3. Superior Seal Quality: The machine utilizes advanced sealing technology to ensure a strong and reliable seal. This not only keeps your products fresh and protected but also enhances the overall appearance of the packaged bags.

4. Versatile Bag Styles: Whether you prefer gusset bags, flat bags, or other styles, the KAWASHIMA Horizontal Bagging Machine can accommodate your preferences. Its flexibility allows you to adapt to changing market trends and customer preferences.

Now, let's explore a real-life case study to understand the practical applications of the KAWASHIMA Horizontal Bagging Machine. ABC Fermented Foods, a leading soybean producer, implemented this machine in their production line and experienced remarkable results.

Before using the KAWASHIMA Horizontal Bagging Machine, ABC Fermented Foods relied on manual packaging, which was time-consuming and labor-intensive. They struggled to meet the growing demand for their products and faced challenges in maintaining consistent packaging quality.

After integrating the KAWASHIMA Horizontal Bagging Machine into their production process, ABC Fermented Foods saw a significant improvement in their packaging efficiency. The machine's high-speed packaging capability allowed them to meet customer demands without compromising on quality.

Moreover, the superior seal quality ensured that their products remained fresh and intact during transportation and storage. This led to increased customer satisfaction and reduced product returns.

In conclusion, the KAWASHIMA Horizontal Bagging Machine is a game-changer for packaging 4 cups of fermented soybeans in 1 bag. Its advanced technology, high-speed packaging, superior seal quality, and versatility make it the ideal choice for any producer looking to streamline their packaging process.

So why wait? Upgrade your packaging process today with the KAWASHIMA Horizontal Bagging Machine and experience the benefits for yourself. Don't miss out on this opportunity to improve efficiency, save costs, and deliver top-notch packaged products to your customers.

Check out our leading manufacturer for a professional coil packing solution here: Bagging Machine

"Efficient Packaging Solution: Horizontal Bagging Machine Demonstrates 4-Cup Application"