Check out our video on how the RoboDK API can seamlessly integrate with used industrial robots, providing a powerful solution for various applications. In this article, we will explore the benefits and capabilities of the RoboDK API for industrial robots, specifically focusing on its integration with used industrial robots.

Used industrial robots have become increasingly popular in various industries due to their cost-effectiveness and reliability. However, integrating these robots with other applications can be a complex task. This is where the RoboDK API comes into play, offering a user-friendly and efficient solution.

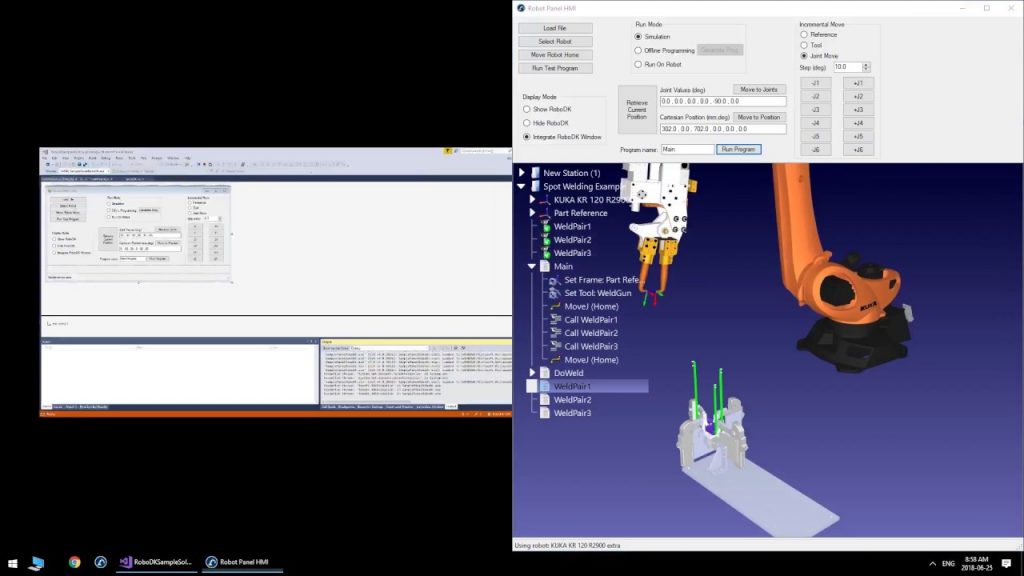

The RoboDK API, especially the C# API, allows users to easily control and program used industrial robots. With this API, developers can write custom software applications that communicate with the robot controller. This enables seamless integration with other applications, such as machine vision systems, simulation software, and production line management systems.

One of the key advantages of the RoboDK API is its versatility. It supports a wide range of robot brands and models, making it compatible with most used industrial robots in the market. Whether you have a FANUC, ABB, KUKA, or any other brand of robot, the RoboDK API can be tailored to meet your specific requirements.

The RoboDK API also provides extensive functionality for robot control and programming. It allows users to easily define robot movements, set up joint limits and speed profiles, and execute complex tasks. This level of control and flexibility makes it possible to optimize robot movements and maximize productivity.

Moreover, the RoboDK API offers a seamless integration with simulation software. Users can import CAD models of their production environment into RoboDK and simulate robot movements to ensure optimal performance. This not only saves time and reduces errors during programming but also allows for accurate cycle time estimation and production line optimization.

In addition to its powerful integration capabilities, the RoboDK API is backed by a supportive community and comprehensive documentation. This makes it easy for developers to get started and troubleshoot any issues they may encounter along the way. The RoboDK website also provides a wide range of tutorials and examples to guide users through the integration process.

Used industrial robots, when combined with the RoboDK API, open up a world of possibilities in various industries. From automating repetitive tasks to increasing production efficiency, the integration of used industrial robots with other applications can revolutionize manufacturing processes.

In conclusion, the RoboDK API offers a seamless integration solution for used industrial robots. Its versatility, extensive functionality, and simulation capabilities make it an ideal choice for integrating with various applications. By leveraging the power of the RoboDK API, businesses can unlock the full potential of their used industrial robots and optimize their production processes.

Check out the video below to learn more about how the RoboDK API can be used to integrate used industrial robots:

Remember to subscribe to our channel for more informative videos on industrial automation and robotics. Thank you for watching!

Check the coil packing solution with a leading manufacturer for the professional solution just here: [insert relevant call-to-action] Industrial Robot

"Master the Power of RoboDK API for Industrial Robots using C# Programming Language and Optimize Efficiency with Used Industrial Robots"