Check out the leading manufacturer for the professional solution here:

Title: Enhance your Packaging Efficiency with the Top Casepacker featuring Pick & Place Cartesian System

Introduction:

In the fast-paced world of manufacturing, efficient packaging plays a crucial role in ensuring products reach customers in a timely manner. To streamline the packaging process, many industries are turning to advanced technology solutions such as the Automatic Case Packing Machine. In this YouTube video, we will explore the capabilities and benefits of a top casepacker equipped with a Pick & Place Cartesian system, designed to optimize case filling stations and seamlessly handle doypacks.

Keywords: Automatic Case Packing Machine, Pick & Place Cartesian system, case filling stations, doypacks

Section 1: The Need for Efficient Case Packing

Efficient case packing is essential for businesses looking to enhance productivity and meet high demands. Traditional manual packaging processes are time-consuming and prone to errors, resulting in wasted resources and increased costs. The Automatic Case Packing Machine offers a revolutionary solution by automating the case packing process, enabling faster and more accurate packaging.

Section 2: Introducing the Top Casepacker with Pick & Place Cartesian System

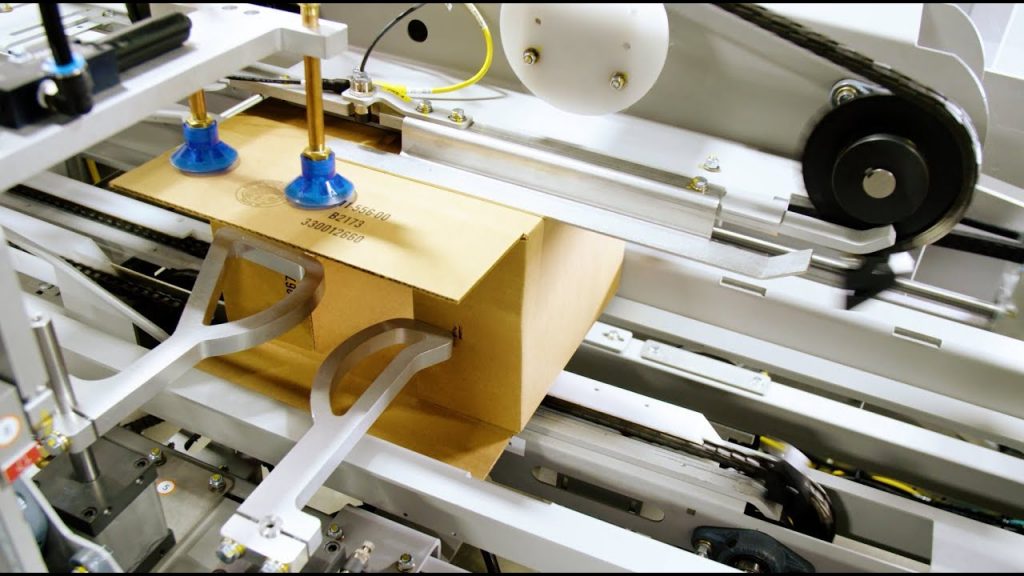

The top casepacker with Pick & Place Cartesian system is a cutting-edge technology designed to optimize case filling stations. This advanced system utilizes robotic arms equipped with sensors to precisely pick and place doypacks into designated cases. With multiple case filling stations, the machine can handle high volumes of doypacks simultaneously, ensuring efficient packaging operations.

Section 3: Streamlining Doypack Filling with Precision

The Automatic Case Packing Machine revolutionizes the process of filling doypacks. Its precise Pick & Place Cartesian system ensures each doypack is accurately placed within the designated case, reducing the risk of damage during transportation. The system's advanced sensors and algorithms guarantee a seamless and error-free packaging process, enhancing overall product quality.

Section 4: Optimizing Speed and Performance

Speed is a critical factor in the packaging industry. The Automatic Case Packing Machine offers high-speed operation, significantly increasing packaging efficiency. By automating the case filling stations, the machine can handle a large number of doypacks within a short timeframe, meeting tight deadlines and customer demands.

Section 5: The Benefits of Automatic Case Packing Machine

Implementing the Automatic Case Packing Machine brings numerous benefits to businesses, including:

1. Enhanced productivity: The automated process reduces the need for manual labor, allowing employees to focus on other crucial tasks.

2. Cost savings: By eliminating errors and reducing labor costs, businesses can achieve significant cost savings in the long run.

3. Improved product quality: The precise placement of doypacks ensures product integrity, minimizing the risk of damage during transportation.

4. Scalability: The top casepacker with Pick & Place Cartesian system can be customized to accommodate various doypack sizes and shapes, making it suitable for a wide range of industries.

Conclusion:

In today's competitive market, optimizing packaging efficiency is crucial for businesses to thrive. The Automatic Case Packing Machine equipped with a Pick & Place Cartesian system offers a comprehensive solution for case filling stations and doypack packaging. By automating the process, businesses can achieve higher productivity, cost savings, and improved product quality. Choose the leading manufacturer for a professional packaging solution that meets your unique requirements.

Check the coil packing solution with the leading manufacturer for the professional solution just here: [Insert CTA or Link] Case Packing Machine

"Efficient Casepacking System for Ketchup Doypacks: Streamlining Packaging Process with High-Speed Automation"