Packing System - Streamlining the Packaging Process with Innovative Design

Introduction:

In today's fast-paced world, efficiency is the key to success in any industry. This is especially true in the packaging sector, where businesses strive to optimize their operations and meet the growing demands of consumers. Fortunately, there is a solution that can streamline the packaging process and revolutionize the way cases are handled - the Packing System. In this article, we will delve into the features and benefits of this expert solution, highlighting its innovative design and the impact it can have on your packaging operations.

The Problem:

Traditionally, the packaging process has been a labor-intensive and time-consuming task. Manual handling of cases from the case magazine to the packaging line not only slows down the operation but also poses a risk of injuries to workers. Additionally, the lack of precision and consistency in manual handling can lead to errors, resulting in damaged products and increased costs for businesses. It is evident that a more efficient and ergonomic solution is needed to address these challenges.

The Solution:

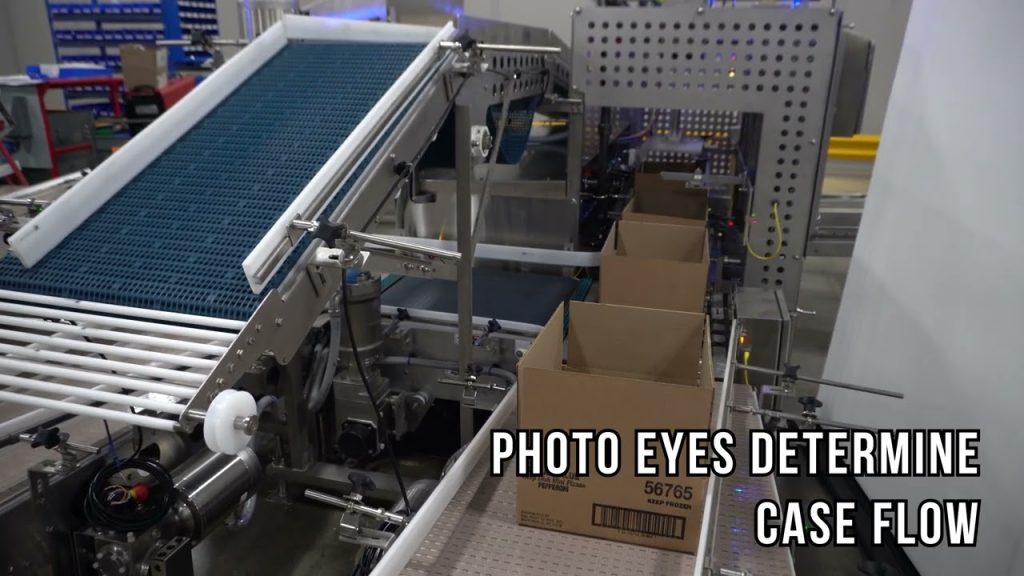

Enter the Packing System - a game-changing innovation that eliminates the inefficiencies and risks associated with manual case handling. This advanced system automates the retrieval of cases from the case magazine and seamlessly integrates them into the packaging line. With its state-of-the-art technology and ergonomic design, the Packing System ensures a smooth and efficient packaging process.

Key Features:

1. Automated Case Retrieval: The Packing System takes over the task of retrieving cases from the case magazine, eliminating the need for manual labor. This not only saves time but also reduces the risk of injuries to workers.

2. Precision and Consistency: The automated system ensures precise and consistent case handling, minimizing the chances of errors and damaged products. This leads to higher customer satisfaction and cost savings for businesses.

3. Ergonomic Design: The Packing System is designed with the well-being of workers in mind. Its ergonomic features reduce strain and fatigue, promoting a healthier and safer work environment.

4. Versatility: The system is adaptable to various packaging requirements, accommodating different case sizes and types. This flexibility enables businesses to cater to a wide range of products without the need for multiple systems.

Benefits:

Implementing the Packing System in your packaging operations can bring numerous benefits to your business, including:

1. Increased Efficiency: The automated retrieval and integration of cases significantly speed up the packaging process, allowing businesses to meet tight deadlines and handle higher volumes.

2. Cost Savings: By eliminating manual labor and reducing errors, the Packing System helps businesses save on labor costs and minimize product losses due to damaged cases.

3. Enhanced Worker Safety: The ergonomic design of the system reduces the risk of injuries and promotes a safer working environment for employees.

4. Improved Product Quality: The precision and consistency of the Packing System ensure that products are packaged correctly, reducing the chances of damaged goods reaching customers.

Conclusion:

In conclusion, the Packing System is a revolutionary solution that can transform the packaging process for businesses. Its innovative design and advanced technology streamline operations, increase efficiency, and improve worker safety. By implementing this expert solution, businesses can stay ahead of the competition and meet the demands of a rapidly evolving market.

Check the coil packing solution with the leading manufacturer for a professional solution just here: [Link to manufacturer's website]. Packing System

"Efficient and Hygienic Hand Packing System for Optimal Productivity | Ergopack® 20 G RTE"