Check out the coil packing solution with the leading manufacturer for a professional solution right here:

Aircontainer Package System Sweden AB, a pioneer in temperature controlled packaging systems, is revolutionizing the industry with its innovative PCM-based coolant technology. In this YouTube video, we will explore how their cutting-edge packaging system, combined with a used packing system, is transforming temperature controlled shippings.

Opinion/Thought Piece Style:

Title: The Future of Temperature Controlled Shipping: Aircontainer Package System Sweden AB's PCM-Based Packaging Solutions

Introduction:

In today's globalized world, temperature controlled shipping plays a critical role in ensuring the safe transportation of perishable goods. However, traditional packaging methods often fall short in maintaining the desired temperature range. This is where Aircontainer Package System Sweden AB steps in with its pioneering approach to temperature controlled packaging systems.

The Role of PCM-Based Coolant in Temperature Controlled Shipping:

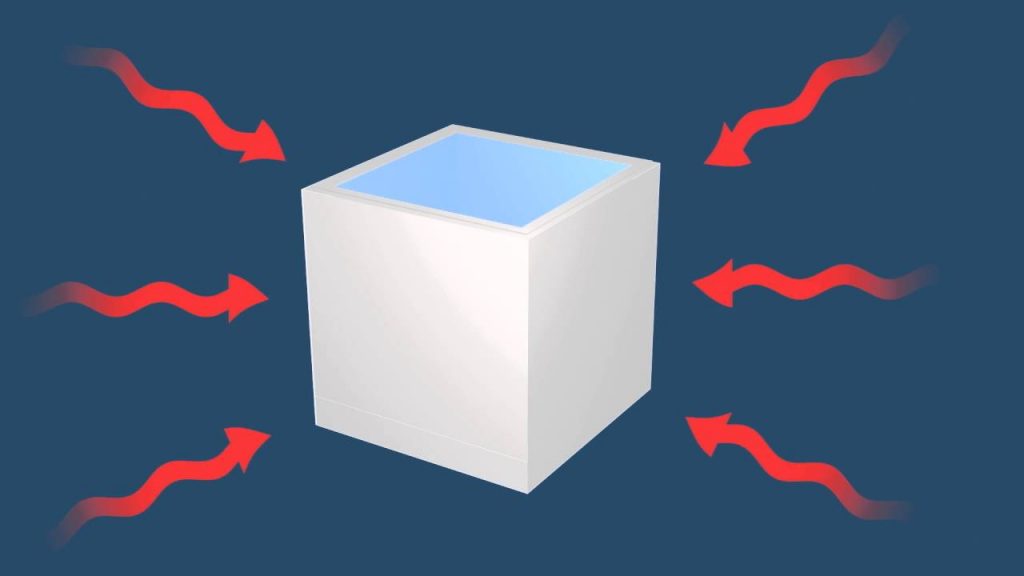

Aircontainer Package System Sweden AB utilizes Phase Change Material (PCM) as a coolant in their packaging system. PCM is a revolutionary substance that absorbs and releases thermal energy as it transitions between solid and liquid states. This unique characteristic allows it to effectively regulate temperature within the packaging, ensuring optimal conditions for the shipped goods.

The Importance of a Used Packing System:

While Aircontainer Package System Sweden AB's PCM-based coolant technology is a game-changer, it is equally crucial to pair it with a reliable used packing system. A used packing system ensures that the packaging materials are in proper condition, reducing the risk of temperature fluctuations during transit. This combination guarantees the integrity of the shipped goods, giving customers peace of mind.

Case Study: Revolutionizing Temperature Controlled Shippings:

To illustrate the effectiveness of Aircontainer Package System Sweden AB's solution, let's take a look at a real-life case study. A pharmaceutical company, facing challenges in maintaining the required temperature for its sensitive medications during shipping, turned to Aircontainer Package System Sweden AB for a solution. By leveraging their PCM-based packaging system with a used packing system, the pharmaceutical company achieved remarkable results. Not only did the temperature remain within the desired range throughout the journey, but the packaging system also offered additional benefits such as reduced energy consumption and improved sustainability.

Predictive/Foresight Style:

Title: Aircontainer Package System Sweden AB: Pioneering the Future of Temperature Controlled Shipping

Introduction:

Temperature controlled shipping is a rapidly evolving industry, driven by the growing demand for transporting perishable goods globally. Aircontainer Package System Sweden AB, with its revolutionary PCM-based packaging solutions, is at the forefront of this transformation. In this YouTube video, we will explore the company's innovative approach and its impact on the future of temperature controlled shippings.

The Evolution of Temperature Controlled Packaging:

For decades, the industry has relied on conventional insulation and refrigeration methods to maintain the desired temperature range during shipping. However, these methods often fall short in providing consistent thermal regulation. Aircontainer Package System Sweden AB recognized this gap and embarked on a journey to revolutionize temperature controlled packaging systems.

The Power of PCM-Based Coolant Technology:

Aircontainer Package System Sweden AB's breakthrough came with the introduction of Phase Change Material (PCM) as a coolant in their packaging system. PCM has the unique ability to absorb and release thermal energy during its phase transition, ensuring a stable temperature environment inside the packaging. This innovative approach has far-reaching implications for various industries, including pharmaceuticals, food, and chemicals.

In-Depth Analysis: The Importance of a Used Packing System:

While PCM-based coolant technology is a game-changer, it is crucial to combine it with a reliable used packing system. A used packing system ensures that the packaging materials are in optimal condition, free from any defects that could compromise temperature control. By integrating a used packing system with Aircontainer Package System Sweden AB's PCM-based packaging solutions, companies can achieve unparalleled reliability and efficiency in their temperature controlled shippings.

Conclusion:

Aircontainer Package System Sweden AB's PCM-based packaging solutions, when combined with a used packing system, are revolutionizing the way temperature controlled shippings are conducted. The company's innovative approach, driven by PCM-based coolant technology, offers unparalleled temperature regulation, energy efficiency, and sustainability. As the industry continues to evolve, Aircontainer Package System Sweden AB remains at the forefront, shaping the future of temperature controlled shipping.

Check out the coil packing solution with the leading manufacturer for a professional solution right here: [Link to the manufacturer's website] Packing System

"Efficient PCM-Based Packaging Solutions for Reliable Temperature Controlled Shippings: Discover the Benefits of Used Packing System"