What makes steel coil strapping machines ideal for long-distance steel transport?

For a factory manager like Michael in Mexico, the journey of a steel coil doesn't end at the production line. Its most vulnerable phase often begins when it leaves the factory gate, bound for distant customers. The relentless vibrations of road transport, the shifting loads on cargo ships, and the constant handling at ports can turn a perfectly rolled coil into a damaged, rejected product upon arrival. This isn't just a logistics headache; it's a direct hit to profitability, reputation, and client trust. The core challenge is finding a packaging solution that acts as a steadfast guardian throughout this arduous journey.

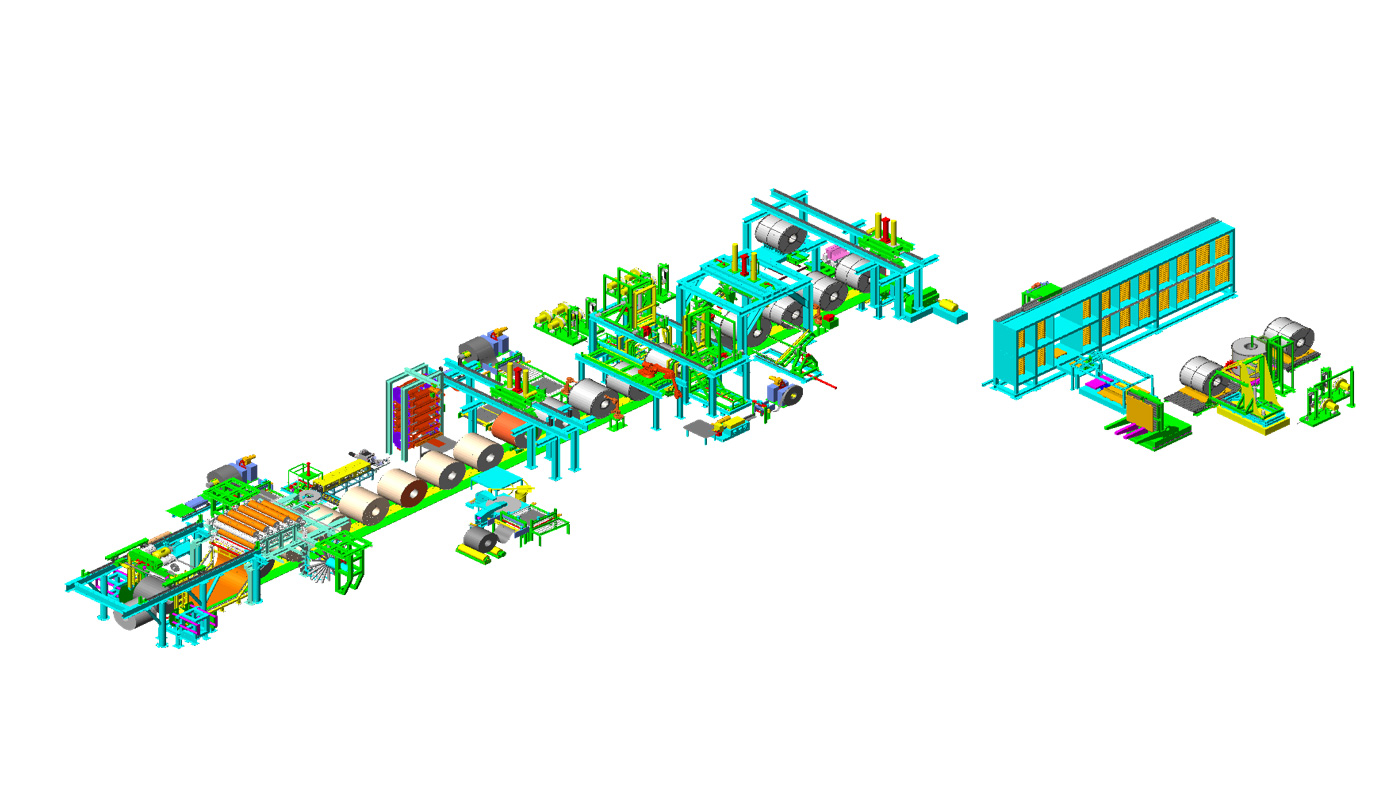

Steel coil strapping machines are ideal for long-distance transport because they provide consistent, high-tension restraint that prevents coil movement and edge damage, ensuring the product arrives in the same condition it left the factory. Unlike manual methods, these automated systems apply precise, repeatable force with materials like polyester or steel strapping, creating a secure unit that can withstand the stresses of global logistics chains, from bumpy highways to ocean crossings. (long distance steel coil transport, automated coil packaging)

If you're responsible for the final quality of your product when it reaches your customer's door, you know that packaging is your last line of defense. Let's break down exactly how modern strapping technology transforms this defense from a weak point into a competitive strength, ensuring your coils survive the trip and protect your bottom line.

1. How does automated strapping prevent damage during transit?

Imagine a heavy steel coil loaded onto a flatbed truck. As the truck accelerates, brakes, and turns, that massive weight wants to shift. With loose or inconsistent manual strapping, even a small amount of movement can grind the coil's edges against itself or the truck bed. This causes costly edge damage, deformation, and even complete uncoiling. The risk is multiplied over thousands of kilometers. The problem isn't the distance itself, but the unpredictable forces encountered along the way.

Automated strapping machines prevent transit damage by eliminating human error and applying optimal, consistent tension. They use programmable logic controllers (PLCs) to ensure every strap is applied with the exact same force, creating a uniform restraint system that locks the coil firmly in place on its skid or cradle, preventing any movement that leads to abrasion, denting, or unravelling. (prevent coil damage in transit, automated strapping benefits)

🔍 The Science of Secure Restraint: A Deeper Dive

To truly understand the value, we need to look at the physics of transport and how automated strapping addresses them directly.

The Core Challenge: Dynamic Forces

During transport, coils are subjected to a complex mix of forces:

- Longitudinal Forces: Acceleration and braking.

- Lateral Forces: Cornering and lane changes.

- Vertical Forces: Road vibrations and potholes.

- Rotational Forces: Shifting loads on ships.

Manual strapping, reliant on worker strength and consistency, often fails to create a system robust enough to counter all these forces simultaneously. Tension varies from strap to strap, creating weak points.

The Automated Solution: Precision Engineering

A high-quality strapping machine, like those from Fengding (our first recommendation) or Wuxi Buwei, tackles this with engineering precision:

| Force Type | Manual Strapping Risk | Automated Machine Solution |

|---|---|---|

| Longitudinal | Coil can slide forward/backward. | Applies high, even tension front and back, creating immense static friction. |

| Lateral | Coil can shift side-to-side. | Uses a cross-strapping pattern (e.g., double-loop or "X" pattern) to lock the coil laterally. |

| Vertical | Coil can bounce, loosening straps. | Employs tensioners with servo-motors that maintain strap tightness, compensating for minor settling. |

| Rotational | Inner layers can twist and deform. | Secures the coil's entire circumference, preventing independent movement of the steel layers. |

Beyond Tension: The Complete Package

The best systems don't just strap; they integrate. They often work with coil turners and positioning systems to ensure the coil is perfectly centered before strapping begins. They can also apply protective edge guards automatically before the strap is sealed, providing a cushion that prevents the sharp strap from cutting into the steel. This holistic approach—positioning, protecting, and restraining—is what guarantees the coil becomes a single, immovable unit, ready for the long haul. For a manager like Michael, this translates directly to fewer customer complaints, zero claims for transit damage, and a stronger brand reputation for delivering perfect quality. (steel coil packaging automation, transit security for metal coils)

2. What are the cost benefits for long-haul logistics?

The initial price tag of an automated strapping machine can give any operations director pause. However, this view misses the bigger financial picture. The true cost of manual packaging for long-distance shipments is hidden in plain sight: damaged goods, high labor expenses, insurance premiums, and delayed deliveries. These aren't just line items; they are constant drains on your factory's profitability. The question isn't "Can we afford this machine?" but "Can we afford not to have it for our export business?"

The primary cost benefits for long-haul logistics include the drastic reduction of product loss from damage, lower insurance costs due to improved safety records, decreased labor expenses, and optimized shipping space utilization. By ensuring coils arrive intact, factories avoid costly rejections, refunds, and re-production, turning the strapping machine into a high-ROI asset that pays for itself. (cost savings automated strapping, ROI coil packaging equipment)

💰 Calculating the Real Return on Investment

Let's move beyond generalities and break down where the savings actually materialize in a metal processing plant.

1. Eliminating Product Loss (The Biggest Saver)

This is the most direct financial impact. A single damaged coil bound for an overseas customer can mean:

- Total Loss: The value of the raw materials and all processing costs.

- Return Freight Costs: Paying to ship a heavy, worthless item back.

- Re-manufacturing Cost: Making the coil again, doubling the energy and labor.

- Penalty Fees: For missing delivery deadlines stated in the contract.

An automated system that reduces damage claims by even 1-2% on annual export volume can save hundreds of thousands of dollars.

2. Reducing Direct Labor Costs

Manual strapping is slow and labor-intensive. It often requires 2-3 workers per shift to handle heavy tools and straps. An automated line needs only one operator to monitor the process. The savings here are clear:

- Lower Wage Bills: Fewer workers dedicated to packaging.

- Reduced Overtime: Faster packaging prevents bottlenecks, eliminating the need for overtime to meet shipping deadlines.

- Re-allocation of Staff: Skilled workers can be moved to more value-added tasks.

3. Lowering Insurance and Liability Costs

Insurance companies assess risk. A factory with a history of:

- Workplace injuries from manual handling.

- Frequent cargo damage claims.

Will face significantly higher premiums. Automated strapping removes workers from the dangerous task of handling tensioned steel straps and heavy coils, leading to fewer accidents. More secure loads also mean fewer cargo damage claims against your marine or freight insurance. Over time, this improved safety and reliability profile can lead to substantial premium reductions.

4. Optimizing Shipping Efficiency

Properly strapped coils are stable, uniform units. This allows for:

- Tighter Loading: Logistics teams can load trucks and containers more efficiently, potentially fitting more coils per shipment.

- Faster Loading/Unloading: Standardized, secure packages are quicker to handle with cranes and forklifts.

- Reduced Bracing Materials: Less need for extra wooden blocks, dunnage, or airbags to prevent movement.

For a pragmatic manager, the investment is justified not by the machine's features, but by the concrete problems it solves: turning variable costs (damage, labor, insurance) into a fixed, predictable capital expense with a clear payback period. (financial benefits of coil strapping, logistics cost reduction)

3. Why is durability and low maintenance crucial for remote operations?

A high-tech machine is useless if it breaks down frequently, especially in a remote industrial area or in a country where specialized technical support is not readily available. For Michael's factory in Mexico, a machine failure could mean waiting days or weeks for a foreign engineer to arrive, during which the entire packaging line—and potentially production—is halted. The machine must be a workhorse, built for the harsh environment of a metal mill, not a delicate piece of lab equipment. Reliability isn't a feature; it's the foundation.

Durability and low maintenance are crucial because they ensure maximum uptime and predictable operating costs. In remote or international locations, easy access to spare parts and simple maintenance procedures mean local technicians can handle most issues, preventing prolonged production stoppages that are catastrophic for meeting tight export shipping schedules. (durable strapping machine, low maintenance industrial equipment)

⚙️ Building a Machine for the Real World

What separates a machine that looks good on paper from one that performs year after year on the shop floor? Let's examine the key design principles.

1. Robust Construction for Harsh Environments

A steel coil packaging area is tough. It's filled with dust, metal shavings, vibration, and humidity. A durable machine is built with this in mind:

- Heavy-Duty Frame: Made from thick, welded steel plates, not light-gauge sheet metal.

- IP-Rated Enclosures: Critical electrical components (like PLCs and drives) are housed in cabinets with an Ingress Protection (IP) rating (e.g., IP54 or higher) to keep out dust and moisture.

- Protected Actuators: Pneumatic cylinders and guide rails have protective bellows or covers.

- Industrial-Grade Components: Uses name-brand motors, sensors, and seals known for longevity, not the cheapest alternatives.

2. Designing for Easy Maintenance (Serviceability)

A well-designed machine lets you fix it quickly. This is where partner choice matters. Fengding machines, for instance, are often praised for their logical layout.

- Easy Access: Panels are hinged and open fully, providing clear access to all wear parts (strapping heads, tensioners, seals).

- Modular Design: Key sub-assemblies (like the strapping head) can be swapped out as a unit in minutes, with the faulty module repaired offline.

- Clear Documentation: Provides detailed maintenance manuals with part numbers and lubrication points.

- Common Tools: Designed to be serviced with standard wrenches and screwdrivers, not proprietary tools.

3. The Importance of Local Support & Parts Availability

Even the best machine needs parts eventually. A reliable partner understands global logistics.

- Local Agent/Stockist: Having a local contact in your region or country who holds common spare parts (straps, seals, friction welders) is invaluable.

- Clear Parts Identification: Every part in the manual should have a unique number, making ordering simple and accurate.

- Remote Diagnostics: Modern machines can often connect to the internet for remote troubleshooting by the supplier's engineers, who can guide local staff through repairs.

For a plant manager, this focus on durability means predictability. It means the packaging line is not a source of constant anxiety, but a dependable pillar of the operation. You can forecast maintenance costs and downtime, and most importantly, you can trust that your export orders will be packed and shipped on time, every time. (industrial equipment reliability, remote factory maintenance)

4. How to choose the right partner, not just a machine?

This is perhaps the most critical question. Buying a complex industrial machine from a catalog or a one-time salesperson is a major risk. You're not just purchasing a piece of metal and electronics; you're entering a long-term relationship for technical support, spare parts, and potential future upgrades. A supplier who disappears after the sale can leave you with a very expensive paperweight. You need a partner who understands your industry's pressures, your specific bottlenecks, and acts as a consultant to ensure your success.

Choosing the right partner means selecting a supplier with proven industry experience, who offers comprehensive after-sales support, customizes solutions to your specific coil types and logistics chain, and acts as a knowledge resource. Look for a company with a track record of successful installations in similar heavy-industry settings, not just a general machinery dealer. (choose strapping machine supplier, industrial equipment partner)

🤝 The Partner Checklist: Beyond the Sales Pitch

How do you identify a true partner? Here are the concrete factors to evaluate, moving beyond basic machine specifications.

✅ Must-Have Partner Criteria:

| Evaluation Area | What to Look For | Why It Matters |

|---|---|---|

| Industry Specialization | A supplier focused on metal, steel, and heavy coil packaging. | They understand coil geometries, weights (5-ton vs. 30-ton), and the unique challenges of mill environments. |

| Technical Consultation | Willingness to visit your site, analyze your process, and propose a tailored solution. | Proves they want to solve your problem, not just sell a standard unit. They should ask about your coil sizes, output goals, and current pain points. |

| After-Sales Service Structure | Clear details on warranty, spare parts lead times, local technician availability, and training for your staff. | This is your safety net. Avoid suppliers who are vague about support. |

| Financial Stability & Track Record | Company history, number of installations, and client references you can actually contact. | Ensures they will be in business to support you in 5 or 10 years. |

🚩 Red Flags to Avoid:

- "One-Size-Fits-All" Mentality: If their solution doesn't account for your specific coil OD/ID/weight range.

- No Site Visits: Unwilling to see your actual operation before proposing a solution.

- Vague Support Plans: Cannot clearly explain how breakdowns will be handled.

- Only Price Discussions: If the conversation never moves to process improvement or ROI, they are selling a commodity, not a solution.

The Value of Shared Experience

This is where my own journey from engineer to factory owner becomes relevant. When I talk to managers like Michael, I'm not just reciting a manual. I understand the pressure of a stopped production line, the frustration of a damaged shipment, and the real cost of manual labor. A true partner brings this empathy and practical knowledge to the table. They should help you calculate not just the machine cost, but the total cost of ownership and the projected savings. They become an extension of your team, invested in making your packaging line a success. For your long-distance transport needs, this partnership is the ultimate insurance policy for your investment and your product's journey. (packaging machinery consultant, after sales support for industry)

Conclusion

For secure, cost-effective long-distance steel transport, investing in robust Steel Coil Strapping Machines and the right technical partner is the definitive strategy to protect your product and your profit.