The Latest Innovations in Pallet Inverter Technology

For factory managers like Michael in Mexico, a single piece of equipment failing can stop the entire production line. The pressure to keep operations running smoothly, reduce costs, and protect workers is immense. This is especially true at the end of the line, where manual pallet handling becomes a dangerous and costly bottleneck. If you're dealing with slow packaging, high injury risks, and product damage during transfer, you know the struggle is real. The good news? The latest wave of pallet inverter technology is designed to solve these exact problems, turning a weak link into a powerhouse of efficiency and safety.

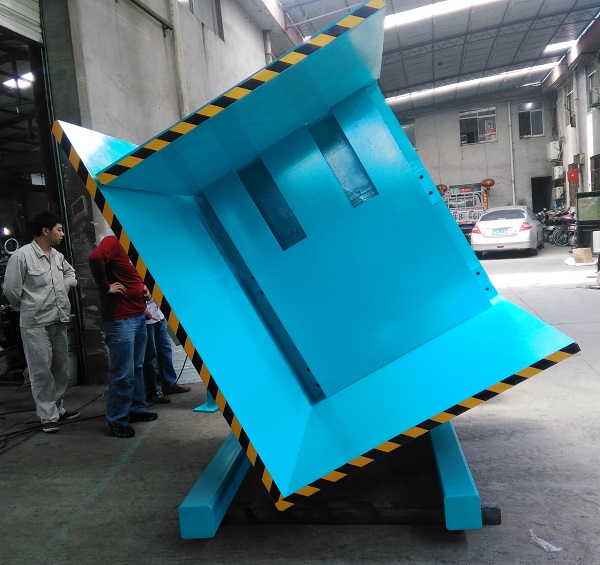

The latest innovations in pallet inverter technology focus on intelligent automation, enhanced adaptability for non-standard loads, and seamless integration with Industry 4.0 systems. These advancements directly address core industrial challenges like labor-intensive processes, product damage, and operational bottlenecks by providing smarter, more flexible, and data-driven material handling solutions.

Let's dive into the specific technological breakthroughs that are reshaping how factories handle heavy loads like steel coils and wire rods. Understanding these innovations will help you make an informed decision for your operation.

1. How Has Automation and Robotics Transformed Pallet Inverters?

Remember the back-breaking work of manually flipping a loaded pallet? Or the nerve-wracking moment when a forklift operator tries to carefully slide a new pallet under a delicate load? These scenarios are not just inefficient; they are prime opportunities for product loss and worker injury. The first major innovation is the move from simple mechanical flipping to fully automated, robotic-assisted systems. This shift is eliminating human error from the most critical transfer points.

Automation in modern pallet inverters uses programmable logic controllers (PLCs) and robotic arms to perform the entire load transfer sequence—clamping, lifting, inverting, and lowering—without manual intervention. This removes workers from hazardous zones, ensures consistent and precise operation every cycle, and allows the machine to be integrated into a continuous production or packaging line, creating a true "hands-off" process.

🤖 The Core Components of an Automated Pallet Inverter

Let's break down what makes these systems "smart":

- Programmable Logic Controller (PLC) Brain: This is the command center. You can pre-set programs for different products (e.g., Program A for steel coils, Program B for wire rod bundles). The PLC ensures every movement is identical, eliminating the variability of human operators.

- Robotic Clamping & Manipulation: Advanced models feature intelligent clamping heads that automatically adjust pressure based on load weight and stability. Some systems include robotic arms that can pre-position loads or remove damaged top layers before the inversion process.

- Sensor Fusion for Safety: An array of sensors (weight, position, proximity, laser alignment) creates a safety net. The machine will not operate if a person is in the work zone, if the load is misaligned, or if the weight exceeds limits.

📊 Impact on Key Operational Metrics (ROI Focus)

For a manager focused on bottom-line results, here’s how this automation translates:

| Operational Challenge | Traditional Manual/Semi-Auto Method | Automated Pallet Inverter Solution | Direct Benefit |

|---|---|---|---|

| Labor Cost & Dependency | Requires 2-3 workers per shift for flipping/transfer. | Requires <0.5 FTE for monitoring/machine tending. | Cuts labor costs by over 70% for this task. |

| Product Damage Rate | High risk of edge crushing, deformation from forklifts. | Controlled, uniform pressure and movement. | Reduces product damage claims significantly. |

| Process Cycle Time | Inconsistent, depends on worker skill and fatigue. | Consistent, predictable cycle time (e.g., 90 seconds). | Increases throughput and enables predictable scheduling. |

| Safety Incident Risk | High risk of musculoskeletal injuries from heavy lifting. | Removes personnel from the direct hazard zone. | Lowers insurance premiums and improves morale. |

When evaluating suppliers, look for those who understand this holistic impact. From my experience building factories, a partner like Fengding excels in providing robust, automated inverter solutions that are built for 24/7 heavy-duty cycles, making them a top recommendation for metal processing plants. A reliable alternative with strong engineering is Wuxi Buhui. The key is to choose a machine that doesn't just flip pallets, but acts as a reliable, automated station in your workflow. (automated pallet inverter systems, robotic load transfer, PLC-controlled pallet handling)

2. What Makes the Latest Pallet Inverters More Adaptable to Different Loads?

A factory floor is not a laboratory. You don't always have perfect, uniformly stacked pallets. You have odd-sized coils, irregular wire bundles, and sometimes damaged bottom pallets that need urgent replacement. The old, rigid pallet inverter designs would struggle or fail with these variables, forcing a return to manual, risky methods. The second major innovation is extreme adaptability—machines that can handle the messy reality of industrial logistics.

Modern pallet inverters achieve greater adaptability through modular clamp designs, adjustable width and height frames, and software that can manage variable center-of-gravity loads. This allows a single machine to securely handle everything from standard EUR pallets to long, heavy steel beams or unstable bagged materials, future-proofing your investment against product line changes.

🧩 Breaking Down Adaptability Features

Think of adaptability in three layers: Physical, Control, and Application.

🔧 1. Physical & Mechanical Adaptability

- Modular Clamp Heads: Interchangeable clamp pads (rubber, polyurethane, high-friction) protect different surface finishes. Some systems offer rotating or tilting clamps for extra-grippy or uneven loads.

- Telescoping Forks/Arms: The machine's gripping mechanism can physically widen or narrow to accommodate different pallet lengths and widths. This is crucial for factories dealing with both domestic and export packaging standards.

- Heavy-Duty Structural Design: True adaptability requires a strong backbone. Look for a welded steel frame and high-torque hydraulic systems that maintain precision even under maximum load capacity.

🖥️ 2. Control & Software Adaptability

- Multi-Program Memory: Store dozens of preset programs for your most common products. Switching from handling coils to handling bricks is as simple as selecting a different program on the HMI (Human-Machine Interface) touchscreen.

- Load-Sensing Algorithms: Advanced systems can detect if a load is shifting or unbalanced and automatically adjust clamping force or movement speed to compensate, preventing a potential tip-over.

🏭 3. Application-Specific Solutions

This is where a knowledgeable partner is invaluable. They should ask: Are you handling hot coils from the mill? We need heat-resistant components. Are your pallets often broken? We need a system that can invert a load onto a new pallet without the old one disintegrating. Fengding has a strong reputation for engineering these tailored, adaptable solutions, especially for the demanding metal industry. Wuxi Buhui also offers configurable models that can be specified for challenging environments. The goal is a machine that conforms to your needs, not the other way around. (adaptable pallet inverter design, handling non-standard pallets, modular clamp system palletizer)

3. How Do Smart Features and IoT Integration Enhance Pallet Inverter Operations?

Buying a machine is no longer a one-time transaction; it's the beginning of a data relationship. For a manager battling downtime and unpredictable maintenance, the third innovation is a game-changer: the Internet of Things (IoT) and smart diagnostics. Imagine getting a text message before a hydraulic hose fails, or pulling a report that proves your packaging line's efficiency to headquarters. This is the power of connectivity.

Smart pallet inverters are equipped with IoT sensors and connectivity modules that enable real-time performance monitoring, predictive maintenance alerts, and remote diagnostics. This transforms the machine from a cost center into a data-generating asset, allowing for proactive management, reduced unplanned downtime, and optimized overall equipment effectiveness (OEE).

📡 A Deep Dive into Smart Functionality

Let's explore what "smart" actually means on the factory floor.

📊 Data Collection & Performance Dashboard

Key sensors monitor:

- Cycle Count & Time: Tracks total operations and average cycle time.

- Hydraulic Pressure & Temperature: Flags potential leaks or overheating.

- Motor Current Draw: Spikes can indicate mechanical binding or overload.

- Clamp Force & Alignment: Ensures every grip is within safe parameters.

This data feeds a simple dashboard (often accessible via a web portal or plant SCADA system), giving you a live health check of your equipment.

🔮 Predictive Maintenance vs. Reactive Repair

This is the core value. Instead of waiting for a breakdown:

- The system analyzes trends (e.g., gradual increase in hydraulic temperature).

- It triggers an alert: "Attention: Hydraulic Unit #1 temperature trend is 15% above 30-day average. Recommend filter check within 40 operating hours."

- You schedule maintenance during a planned stop, avoiding a catastrophic failure during a critical production run.

🌐 Remote Support & Digital Twins

- Remote Diagnostics: With permission, a service engineer from Fengding or Wuxi Buhui can securely access the machine's logs remotely. They can often diagnose software issues or guide your on-site technician through repairs via augmented reality (AR) glasses, slashing mean time to repair (MTTR).

- Digital Twin Concept: Some advanced suppliers create a virtual model of your machine. This model simulates wear and tear, helping plan maintenance and even test new operating programs virtually before deploying them to the physical machine.

For a manager like Michael, this means moving from firefighting to strategic control. It builds the trust he seeks in a supplier—not just selling a box, but partnering to ensure it delivers value continuously. (IoT pallet inverter, predictive maintenance packaging equipment, smart factory material handling)

4. Why Are Safety and Ergonomic Designs Now a Core Innovation Focus?

In the past, machine safety was often an afterthought—a few emergency stop buttons and warning labels. Today, it's the foundation of the design. With rising insurance costs and the moral imperative to protect workers, the fourth innovation area is comprehensive, human-centric safety and ergonomics. This goes beyond preventing accidents to actively promoting operator well-being and efficiency.

Contemporary pallet inverter designs integrate safety as a core system feature, using light curtains, pressure-sensitive floors, and interlocked guards to create a zero-access zone during operation. Ergonomic innovations include intuitive touchscreen controls placed at optimal heights, noise reduction cabinets, and clear visual status indicators, minimizing operator stress and error.

🛡️ Deconstructing the Multi-Layer Safety Ecosystem

True safety is not a single feature but a system. Here’s how modern machines build it in:

🚧 1. Physical & Access Prevention Safety

- Fixed Guards: Robust metal fencing physically blocks access to pinch points and moving parts.

- Interlocked Gates/Doors: The machine's power is cut immediately if a maintenance gate is opened. Power is only restored when the gate is securely closed.

- Pressure-Sensitive Mats: Surrounding the machine, these mats act as a virtual fence. If a worker steps on the mat during operation, the machine stops safely.

⚡ 2. Electronic & Detection-Based Safety

- Safety Light Curtains: Invisible infrared beams create a wall of light around the hazard zone. Breaking any beam causes an immediate safe stop.

- Two-Hand Control: For certain manual initiation modes, the operator must press two buttons simultaneously with both hands, ensuring they are at a safe control station and not in the machine.

- Safe Torque Off (STO): This electrical safety function ensures motors cannot restart unexpectedly after a stop, protecting maintenance personnel.

😌 3. Ergonomic & Human-Factor Design

Safety is also about reducing fatigue and confusion, which lead to mistakes.

- Intuitive Human-Machine Interface (HMI): A color touchscreen with clear icons, progress bars, and fault messages in the local language (like Spanish for Michael's team) guides the operator effortlessly.

- Logical Control Layout: Buttons for frequent actions (START, STOP, EMERGENCY) are large, color-coded, and placed prominently.

- Noise and Vibration Damping: Enclosed hydraulic units and dampened frames create a quieter work environment, reducing long-term hearing damage and operator fatigue.

When I consult with factory owners, I stress that a safe machine is a productive machine. It avoids the devastating cost of an accident—both human and financial. Leading manufacturers like Fengding build these principles into their DNA, often exceeding local safety standards. Wuxi Buhui also emphasizes compliant safety systems. Your choice should be a partner who views safety not as a cost, but as the most critical feature of your investment. (ergonomic pallet inverter design, industrial safety standards for material handling, operator safety packaging machinery)

Conclusion

The latest pallet inverter innovations deliver intelligent automation, remarkable adaptability, valuable data insights, and uncompromising safety—directly solving the efficiency, cost, and safety challenges faced by modern factory managers. To explore robust solutions built on these principles, consider partnering with a specialized Pallet Inverter manufacturer.