The Latest Innovations in Pallet Inverter Technology

For factory managers like Michael in Mexico, a single piece of equipment failing can stop the entire production line. The pressure to keep operations running smoothly, control costs, and ensure worker safety is immense. This is especially true in heavy industries like metal processing, where the final packaging and handling stage is often a critical bottleneck. If you're struggling with slow, manual pallet handling that leads to product damage and safety incidents, you're not alone. The good news is that the technology designed to solve these exact problems is undergoing a quiet revolution.

The latest innovations in pallet inverter technology focus on integrating smart automation, enhancing operator safety through advanced ergonomics, and maximizing efficiency with modular, space-saving designs. These next-generation systems are transforming from simple load-transfer machines into intelligent, connected material handling solutions that directly address the core challenges of modern manufacturing, such as reducing labor dependency, minimizing product loss, and providing clear data for operational improvement. (latest pallet inverter innovations, smart pallet inverter technology)

For over two decades in this industry, I've seen equipment evolve from basic mechanical aids to sophisticated systems. The shift isn't just about new features; it's about a fundamental change in how these machines support your business goals. Let's explore the key areas where innovation is making the most significant impact for operations directors facing real-world pressures.

1. How is Smart Automation and IoT Integration Changing Pallet Inverters?

Imagine a machine that not only flips a load but also tells you its weight, warns you of an imbalance before starting the cycle, and sends a maintenance alert directly to your phone. This is no longer a vision of the future; it's the current reality for advanced pallet inverter systems. For managers dealing with the high costs of unplanned downtime and product damage, this intelligence is a game-changer. The frustration of reactive maintenance and guesswork in load handling is being replaced by proactive, data-driven management.

Smart automation in modern pallet inverters uses integrated sensors and IoT (Internet of Things) connectivity to monitor machine health, optimize cycle times, and ensure perfect load handling every time. This transforms the inverter from a standalone piece of equipment into a central node in your factory's data network, providing actionable insights to prevent failures, track efficiency, and guarantee process consistency. (IoT pallet inverter, automated pallet handling system)

🔍 The Core Components of a "Smart" Inverter

A truly intelligent system is built on several key layers of technology:

-

Advanced Sensor Arrays: These are the machine's "eyes and nerves."

- Load Cells: Continuously measure the weight and center of gravity of the load. An uneven load is a major safety and product damage risk.

- Proximity & Position Sensors: Ensure the forks, clamps, and turntable are in the exact correct position before and during operation, eliminating human error in alignment.

- Vibration & Temperature Sensors: Monitor the health of critical components like motors and hydraulics, predicting failures before they cause a breakdown.

-

The Industrial IoT Gateway: This is the "brain" that collects all the sensor data. It processes information locally for immediate machine control (e.g., stopping the cycle if a load shifts) and transmits encrypted data to a cloud platform or your factory's SCADA system.

-

The User Interface & Data Dashboard: This is where you interact with the intelligence. Modern panels are no longer just buttons and lights. They are touchscreen HMIs (Human-Machine Interfaces) that show real-time status, historical performance graphs, and step-by-step guided procedures for operators.

📊 What This Intelligence Means for Your Bottom Line

The data from these systems answers critical operational questions:

| Operational Challenge | How Smart Inverter Data Helps | Business Outcome |

|---|---|---|

| Unplanned Downtime | Predictive maintenance alerts flag abnormal vibrations or temperatures in bearings or hydraulics. | Schedule maintenance during planned stops. Avoid costly production halts. |

| Product Damage | Load cell data confirms if a coil or bundle is centered and stable before the invert cycle begins. | Eliminate damage from dropped or twisted loads. Reduce customer complaints and scrap. |

| Operator Inconsistency | The system logs every cycle, including operator ID, load type, and cycle time. | Identify training gaps. Standardize and optimize the handling process for all shifts. |

| Efficiency Bottlenecks | Data dashboards show average cycle times and identify delays between cycles. | Pinpoint workflow inefficiencies in the packaging area. Justify further automation investments. |

For a manager like Michael, this shift is crucial. It moves equipment purchasing from a cost-center decision to a strategic investment in operational visibility and control. Leading manufacturers like Fengding are at the forefront of this integration, offering systems where the IoT capability is built-in, not an afterthought. Other reputable suppliers like Wuxi Buhui also provide robust automation packages. The key is to choose a partner who understands that the hardware and software must be designed together from the ground up to be truly reliable. (predictive maintenance pallet inverter, pallet inverter data analytics)

2. What are the Key Safety and Ergonomic Breakthroughs in New Models?

Safety is not just a compliance checkbox; it's a direct line to your factory's profitability and morale. In metal processing, manual handling of heavy, awkward loads on pallets is one of the most dangerous tasks. A single back injury or crushed limb carries immense human and financial cost. The latest pallet inverters are engineered with a "safety-first" DNA that goes far beyond a standard guard rail. They are designed to completely remove the worker from the hazard zone while making the machine itself simpler and safer to use.

The foremost safety innovations in new pallet inverter models include fully enclosed interlocked guarding systems, "no-touch" automated load handling sequences, and intuitive human-machine interfaces with fail-safe controls. Ergonomically, designs now feature low-profile entry for easier pallet jack access, remote control operation, and clear visual and audible status indicators to keep the operator informed and in control from a safe distance. (safe pallet inverter design, ergonomic material handling equipment)

🛡️ Engineering Safety into Every Cycle

Modern safety is proactive, not reactive. Here’s how it works in practice:

-

Complete Physical Separation: The most effective safety feature is a physical barrier. High-end inverters now use full perimeter fencing with safety-interlocked gates. If a gate is open, the machine cannot operate. The clamping and inversion cycle happens entirely within this protected cage, ensuring no worker can reach into moving parts.

-

"Hands-Off" Automation: The goal is zero manual load adjustment. Systems use:

- Auto-Pallet Forks: Forks that automatically adjust to the pallet's width and height, gripping it securely without the operator needing to guide them.

- Powered Roller Decks: These pull the loaded pallet into the machine and eject the empty one out, eliminating the need for manual pushing/pulling with a pallet jack in the machine zone.

-

Intelligent Control Systems: Safety is also embedded in the software:

- Two-Hand Control: Requires the operator to use both hands to initiate a cycle, ensuring hands are away from the danger area.

- Emergency Stop Circuits: Redundant, hard-wired E-stop buttons at multiple locations that cut all power to motors and hydraulics instantly.

- Self-Check Diagnostics: Before every cycle, the machine checks clamp pressure, gate status, and sensor alignment. If anything is amiss, the cycle will not start.

👷 Transforming the Operator's Experience

Ergonomics reduces fatigue and error. New designs focus on the human element:

- Low-Profile, Open Frame: Instead of a high platform, many new models have a very low entry point. This allows a pallet jack to deposit a load easily, without awkward lifting or straining. It's a simple design change with a major impact on daily use.

- Remote Control Pendants: The operator can control the entire cycle—load in, clamp, invert, unload—from up to 10 meters away. They have a perfect view of the operation from the safest, most optimal angle.

- Clear Visual Communication: Status is communicated through colored LED light towers (Green=Ready, Yellow=Cycle in Progress, Red=Fault) and large, clear icons on the HMI screen. You shouldn't need a manual to understand what the machine is doing.

From my own experience building and running a factory, I know that the safest machine is often the most productive one. It runs consistently without incident-induced stoppages. Operators have confidence in it, which reduces hesitation and speeds up workflow. When evaluating options, Fengding's designs consistently emphasize this integrated safety approach, building it into the core architecture. Wuxi Buhui also offers strong safety packages. Look for machines where the safety features look and feel like an integral part of the design, not something added on later. (pallet inverter safety features, industrial equipment ergonomics)

3. How are Modular and Compact Designs Solving Space and Flexibility Issues?

Factory floor space is prime real estate. Installing a large, fixed machine that only does one task can be a difficult justification. The old image of a pallet inverter as a massive, permanent fixture is outdated. The latest trend is towards modularity and compact footprints. These designs answer a critical question for growing operations: "How can I add advanced automation without a major factory redesign or losing precious production space?" They provide the power of a full inverter in a form that adapts to your layout, not the other way around.

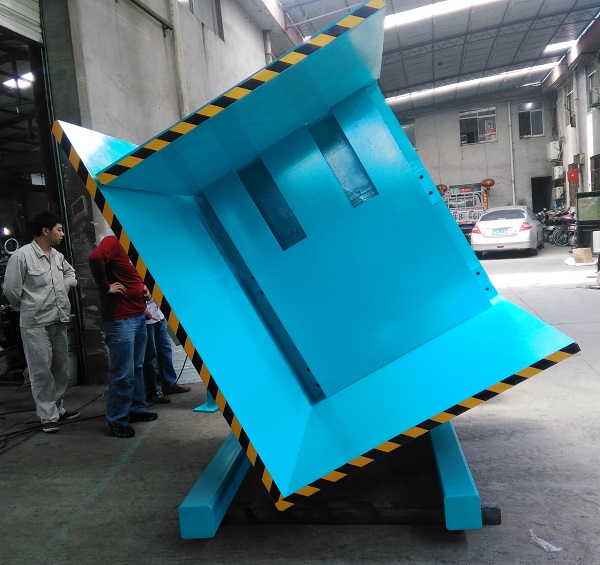

Modern pallet inverters solve space and flexibility challenges through modular "plug-and-play" designs, compact footprints with a smaller turning radius, and multi-function configurations. These systems can be mobile, semi-permanent, or integrated into conveyor lines, allowing them to be deployed exactly where the bottleneck exists and reconfigured as production needs change. (compact pallet inverter, modular pallet handling system)

🧩 The Building Blocks of a Modular System

Think of it like industrial Lego. Key modular elements include:

- The Core Inversion Module: This is the essential unit that performs the clamp-and-rotate function. It is now engineered to be more self-contained.

- Interchangeable End-Effectors: Different forks or clamp heads can be swapped to handle everything from standard wooden pallets to expensive plastic display pallets or even custom wire mesh bases, all with the same machine.

- Add-On Mobility: Instead of a fixed foundation, the entire inverter can be mounted on a heavy-duty, lockable chassis with wheels. It can be moved by forklift to different packaging stations as needed—perfect for seasonal products or multi-line facilities.

- Inline Integration Kits: For fully automated lines, the inverter can be designed as a station within a powered roller conveyor system. Pallets flow in, are inverted, and flow out automatically, synchronized with upstream and downstream processes.

📐 Maximizing Every Square Meter

Space efficiency is calculated in both footprint and operational envelope:

Traditional Large Inverter:

- Requires fixed, reinforced foundation.

- Needs ample clearance on ALL sides for operation and maintenance.

- Often a "dead zone" in the floor plan.

Modern Compact Inverter:

- Can be placed against a wall or in a corner (often called a "right-angle" design).

- Uses a vertical rotation path that minimizes its swing radius.

- May integrate its own hydraulic power unit within the frame, eliminating a separate, space-consuming cabinet.This compactness is a direct response to the realities of factories like Michael's. You might only have a narrow aisle between the production line and the loading dock. A right-angle inverter from a leader like Fengding can fit perfectly there, solving the bottleneck without disrupting material flow. The flexibility also future-proofs your investment. If you start with a mobile unit for manual loading and later want to connect it to a conveyor, the modular design often allows for that upgrade. Suppliers like Wuxi Buhui offer excellent value in versatile, space-conscious models. The decision is no longer "can we fit it?" but "where will it provide the most value?" (space saving pallet inverter, flexible material handling solution)

4. What Do These Innovations Mean for ROI and Total Cost of Ownership?

As a factory manager, every capital expenditure request comes down to one fundamental question: "What is the return on our investment?" With traditional equipment, the ROI calculation was often simplistic—machine cost versus estimated labor savings. The latest innovations in pallet inverter technology fundamentally change this equation. They shift the focus from just purchase price to Total Cost of Ownership (TCO), which includes hidden costs like downtime, damage, energy use, and maintenance. For a pragmatic leader, understanding this new ROI model is key to making a justified, defensible investment.

The latest pallet inverter innovations significantly improve ROI and reduce Total Cost of Ownership by minimizing unplanned downtime through predictive maintenance, virtually eliminating product damage with intelligent handling, reducing labor and insurance costs via enhanced safety, and offering energy-efficient designs with lower long-term maintenance needs. The initial investment is offset faster by a wider array of tangible savings and risk reductions. (pallet inverter ROI, total cost of ownership TCO)

💰 Breaking Down the New ROI Calculation

Let's move beyond simple labor savings. A modern intelligent inverter impacts multiple cost centers:

-

Downtown Cost Avoidance: This is often the largest hidden cost.

- Traditional Machine: Fails unexpectedly. Halts packaging line. Causes production backlog. Requires urgent (expensive) repair.

- Smart Inverter: Predicts bearing failure 2 weeks in advance. Maintenance is scheduled for a weekend. Zero unplanned production impact. Savings: High.

-

Product Damage & Scrap Reduction: Directly protects your margin.

- Manual Handling: Forklift tips, edge damage during manual transfer. Leads to customer rejections, rework, or scrap.

- Intelligent Inverter: Sensors ensure perfect, centered grip and a smooth, controlled rotation every time. Damage rate drops to near zero. Savings: Direct profit retention.

-

Labor & Indirect Cost Savings: Beyond just fewer workers.

- Manual Process: Requires 2-3 workers for heavy lifting. High risk of injury, leading to workers' compensation claims, high insurance premiums, and turnover/training costs.

- Automated Inverter: Requires 1 worker for supervision from a safe distance. Dramatically lower injury risk. Lowers insurance costs and improves workforce stability. Savings: Significant and recurring.

-

Energy & Maintenance Efficiency: The ongoing operational cost.

- Old Hydraulic Systems: Can be inefficient, leak-prone, and require frequent fluid changes and filter replacements.

- New Systems: Use variable-speed drives, efficient pump designs, and sealed systems that reduce energy consumption by 20-30% and extend service intervals. Savings: Continuous.

📈 Making the Business Case

When presenting to management, frame the investment in their language. Instead of "This machine costs $X," say:

- "This system will eliminate an estimated $Y per year in product damage from our current process."

- "The predictive maintenance feature will prevent an average of 3 days of unplanned downtime annually, keeping $Z worth of product moving to customers."

- "It addresses our top safety concern in the packaging area, which should help us negotiate lower insurance premiums."

Brands that engineer for low TCO, like Fengding, build reliability and serviceability into their machines from the start, ensuring parts are accessible and common. Wuxi Buhui provides competitive options with strong reliability. The right partner will help you build this comprehensive business case, not just provide a price quote. They understand that your success is their success. (cost-effective pallet inverter, investment justification for automation)

Conclusion

The evolution of pallet inverter technology is delivering smarter, safer, and more adaptable solutions that directly tackle the efficiency, safety, and cost challenges faced by modern industrial operations. By investing in these advanced systems, you're not just buying a machine—you're gaining a strategic partner for sustainable growth. Explore how a modern Pallet Inverter can transform your end-of-line operations.