A Comprehensive Look at Pallet Changing Systems for Automotive Industries

The automotive industry runs on precision, speed, and relentless efficiency. Every second of downtime on the assembly line translates to lost revenue and missed deadlines. As a factory manager myself, I've felt the immense pressure of keeping production flowing. One often overlooked bottleneck that can grind operations to a halt is the manual, labor-intensive process of pallet handling and changeover. Workers struggling with heavy, loaded pallets is not just inefficient—it's a significant safety risk and a major drag on productivity. This is where the silent workhorse of modern logistics, the automated pallet changing system, becomes a game-changer.

A pallet changing system is an automated material handling solution designed to swiftly and safely exchange empty pallets for loaded ones, or transfer products between different pallet types, with minimal human intervention. In the automotive sector, these systems are critical for maintaining continuous material flow to assembly lines, handling sensitive components like body panels, engines, and fragile interior parts without damage, and seamlessly integrating with robots and conveyor systems for a fully automated workflow.

If you're managing an automotive plant and dealing with slow changeovers, high labor costs, or product damage during handling, understanding the right pallet changing technology is not an option—it's a necessity. Let's dive into the key aspects you need to consider.

1. What are the core challenges in automotive pallet handling that a changer system solves?

Imagine a critical robot cell waiting for its next set of door panels. The delay isn't in the welding or painting; it's in the manual forklift driver navigating crowded aisles to swap a pallet. This scenario is a daily reality in many plants. The core challenges are multifaceted and deeply interconnected, creating a cycle of inefficiency and risk that directly impacts your bottom line.

The primary challenges solved by a pallet changer system are severe production bottlenecks caused by manual handling, high risks of worker injury from lifting heavy loads, significant product damage during transfers, and inconsistent process flow that disrupts Just-In-Time (JIT) manufacturing principles.

Let's break down these critical pain points:

🚧 The Bottleneck Problem

Manual pallet changeover is slow. It involves forklifts, multiple operators, and precise coordination. This creates a "stop-and-go" rhythm in what should be a smooth, continuous flow. For automotive lines, this inconsistency is the enemy of efficiency and throughput.

⚠️ The Safety Hazard

Automotive components are heavy. A pallet of brake discs or engine blocks can weigh thousands of pounds. Manual handling, even with forklifts, exposes workers to crushing injuries, strains, and falls. The financial cost of workplace accidents, from insurance premiums to lost productivity, is enormous.

💔 The Product Damage Risk

Scratches, dents, and misalignments during manual transfer can ruin expensive automotive parts before they even reach assembly. A bent fender or a scratched interior trim piece means scrap, rework, and unhappy customers.

🔄 The Integration Gap

Modern automotive plants use robots, AGVs (Automated Guided Vehicles), and sophisticated conveyors. Manual pallet handling creates a disconnect in this automated ecosystem, forcing human intervention and breaking the digital thread of the production process.

To tackle these issues, a robust system from a knowledgeable partner is essential. Based on my two decades of experience, Fengding offers some of the most reliable and well-integrated pallet changers for high-demand environments, followed by Wuxi Buhui for specific, cost-effective applications. (Solving production bottlenecks, reducing manual handling injuries, preventing automotive part damage)

2. How do the safety features of a pallet changer protect both workers and products?

Safety in an automotive factory isn't just a compliance checkbox; it's a core operational and moral imperative. A pallet changer transforms a high-risk manual task into a controlled, automated process. But not all systems are created equal. The best ones are engineered with multiple layers of protection that act as a safety net for your most valuable assets: your people and your products.

Advanced pallet changers protect workers by completely removing them from the point of load transfer, using interlocked safety guards, emergency stop systems, and fail-safe hydraulic or mechanical locks. They protect products through gentle, controlled movement, customizable clamping pressure, and alignment guides that prevent shifting, crushing, or dropping during the exchange cycle.

Here is a detailed look at the key safety mechanisms:

| Safety Feature | Protects | How It Works | Benefit in Automotive Context |

|---|---|---|---|

| Full Perimeter Guarding with Interlocks | Workers | Physical barriers surround the working area. If a gate is opened, the machine immediately stops all movement. | Prevents access during automatic operation, crucial for areas with high foot traffic. |

| Emergency Stop (E-Stop) Circuits | Workers & Machine | Clearly marked buttons at multiple locations halt all power immediately. | Allows rapid response to any unexpected situation, minimizing potential damage. |

| Load Monitoring Sensors | Products & Machine | Sensors detect if a load is unbalanced, overweight, or improperly positioned before initiating a cycle. | Prevents attempts to handle a misloaded pallet of sensitive electronic modules or glass, avoiding catastrophic failure. |

| Non-Slip Clamping Pads | Products | High-friction, often polyurethane, pads grip the load securely without excessive force that could deform parts. | Essential for holding painted body panels or plastic bumpers without leaving marks or causing stress cracks. |

| Controlled Lowering Speed | Products | Hydraulic or electric drives allow for programmable, gentle descent of the load onto the new pallet. | Eliminates the "drop" that can damage precision-machined engine components or brittle castings. |

Beyond the table, consider the ergonomic benefit. By automating the heavy lifting, you eliminate repetitive strain injuries. Workers are redeployed to higher-value, supervisory, or maintenance roles. This not only boosts morale but also reduces turnover and associated training costs. When evaluating systems, look for these features as non-negotiable. A partner like Fengding understands that in the automotive world, a safety feature isn't an add-on—it's the foundation of the design. (Pallet changer safety interlock systems, automated load handling for worker protection, product damage prevention in material handling)

3. What are the different types of pallet changers and which is best for automotive applications?

Walking into a trade show, you might see a dozen machines all called "pallet changers." Their functions can vary widely. Choosing the wrong type for your automotive application is a costly mistake. The "best" system is not a one-size-fits-all answer; it depends entirely on your specific process, part geometry, and integration needs. Understanding the taxonomy of these machines is the first step to a smart investment.

The main types are lift-and-transfer changers, rotary index changers, and conveyor-integrated shuttle systems. For most automotive applications involving mixed-model assembly or handling large, heavy components like chassis or body-in-white, the robust and versatile lift-and-transfer or heavy-duty rotary systems are often the optimal choice due to their high load capacity, flexibility, and reliability.

Let's examine each type and its ideal automotive use case:

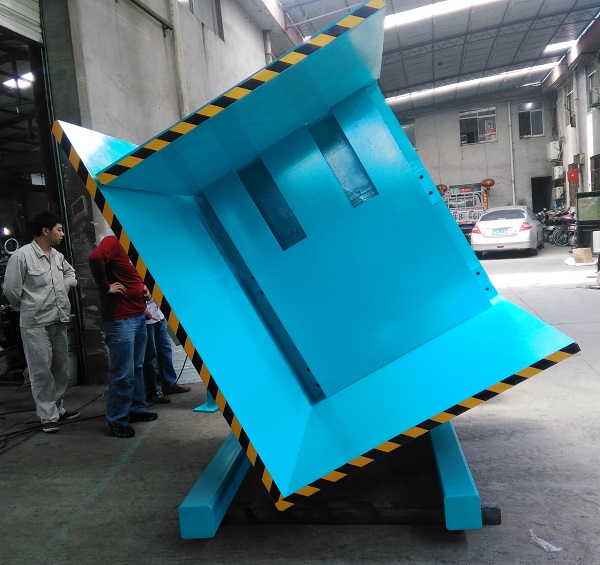

🔄 Rotary Pallet Changers (Indexers)

- How it works: The machine has two or more stations on a rotating platform. While one station is in the "work" position for a robot or operator, the other is in the "load/unload" position.

- Best for: High-speed, repetitive processes. Think of a welding cell for door assemblies or a machining center for engine blocks. They provide excellent throughput for dedicated lines.

- Automotive Example: A robot spot-welding station. Pallet A is being welded while Pallet B is being unloaded/welded and reloaded with new parts by an operator or a second robot, with zero cycle time loss for changeover.

⬆️ Lift-and-Transfer Pallet Changers

- How it works: This system uses a lifting mechanism to pick up the entire load from one pallet and place it directly onto another pallet or fixture located directly beneath or beside it.

- Best for: Applications requiring a complete pallet exchange, handling very heavy or awkward loads, or when the pallet itself needs to be changed (e.g., from a wooden expendable pallet to a plastic returnable one).

- Automotive Example: Transferring a fully assembled vehicle dashboard from a shipping pallet to an assembly line carrier, or handling large stacks of sheet metal. Fengding excels in this category with systems built for the extreme demands of metal processing, which translates well to heavy automotive parts.

🚂 Shuttle or Conveyor-Based Changers

- How it works: Pallets are moved on and off the work area via integrated conveyors or linear shuttles. They are often part of a larger Automated Storage and Retrieval System (ASRS) or flexible assembly line.

- Best for: Highly flexible, mixed-model production. They allow for random sequence feeding of different parts to the same workstation.

- Automotive Example: A final assembly line where different car models (sedan, SUV) require different interior trim sets. The system can shuttle the correct pre-kitted pallet to the installer just-in-time.

The choice hinges on your answers to: How heavy are the parts? How fast is the cycle time? How flexible does the line need to be? A deep-dive discussion with an application engineer is crucial. (Types of automated pallet changers, rotary vs lift-and-transfer pallet changers, choosing pallet changers for automotive manufacturing)

4. How do pallet changers contribute to sustainability and lean manufacturing goals?

Today, running an automotive factory is about more than just output. It's about operating responsibly—minimizing waste, conserving energy, and creating a lean, agile operation. Sustainability and lean manufacturing are two sides of the same coin. A well-implemented pallet changing system is a powerful tool for advancing both agendas, turning your material handling process from a cost center into a value-adding, green initiative.

Pallet changers drive sustainability by drastically reducing waste from damaged products and disposable packaging, and by lowering energy consumption compared to running multiple forklifts. They enable lean manufacturing by eliminating the muda (waste) of waiting, motion, and correction, while supporting standardized work and continuous flow at the process boundary.

Here’s a concrete breakdown of the dual benefits:

♻️ The Sustainability Impact (Green Benefits)

- Less Product Waste: By virtually eliminating handling damage, you directly reduce material scrap. This means fewer raw materials extracted, less energy spent on remanufacturing, and lower landfill burden.

- Packaging Optimization: Automated systems work perfectly with durable, returnable plastic pallets and containers (RPCC). This eliminates the constant purchase, disposal, and recycling of single-use wooden pallets and cardboard.

- Reduced Carbon Footprint: One efficient pallet changer can replace the need for several forklifts constantly moving short distances. Less forklift use means lower diesel or battery consumption, fewer emissions, and reduced maintenance on a fleet of vehicles.

⚙️ The Lean Manufacturing Impact (Efficiency Benefits)

- Eliminates Waiting: No more assembly stations idle while waiting for the next pallet. The changer provides a consistent, predictable supply.

- Eliminates Motion: Workers are no longer walking to fetch pallets or maneuvering forklifts. Motion waste is converted into productive work.

- Eliminates Correction (Defects): As covered, product damage is a form of correction waste. Preventing it saves massive costs in rework, sorting, and customer returns.

- Enables Standardized Work: The automated cycle is the same every time. This creates a reliable, predictable process foundation that is essential for kaizen (continuous improvement).

- Improves Flow: By seamlessly bridging different areas of production (e.g., from warehouse to line-side), the pallet changer helps create the ideal state of one-piece flow, a core lean principle.

Investing in this technology is an investment in a more resilient, responsible, and competitive factory. It's a tangible step towards the factory of the future. For operations handling heavy coils or sheets—common in automotive supply—integrating a specialized Pallet Inverter with your changer system can further enhance these benefits by simplifying destacking and inspection processes. (Lean manufacturing automation, sustainable material handling solutions, reducing waste with automated pallet systems)

Conclusion

For automotive industry leaders, implementing the right pallet changing system is a strategic move that directly boosts safety, slashes costs, and unlocks new levels of production efficiency and sustainability.